Formlabs offers a comprehensive range of advanced 3D printing solutions, including stereolithography (SLA) and selective laser sintering (SLS) technologies. Their SLA printers, such as the Form 4, utilize a laser to cure liquid resin into high-resolution parts with smooth surface finishes. Formlabs provides a wide selection of engineering-grade, dental, medical, and specialty resins to suit various applications. The company’s ecosystem includes user-friendly software like PreForm for print preparation and Dashboard for remote printer management.

Post-processing solutions, such as Form Wash and Form Cure, streamline the finishing process. For higher volume production, Formlabs offers the Form Auto, an automated part removal system that enables 24/7 printing. Their SLS printers, like the Fuse Series, produce durable nylon parts ideal for functional prototypes and end-use components. Formlabs’ advanced 3D printing technologies empower businesses across industries to bring high-quality, custom parts production in-house, reducing costs and accelerating innovation.

The History of Formlabs

Formlabs, a 3D printing giant, was founded in September 2011 by three MIT Media Lab students. From the beginning, the company aimed to revolutionize the industry with its advanced technology and innovative solutions. One of the pivotal moments in Formlabs’ journey was their highly successful Kickstarter campaign, which raised nearly $3 million.

This groundbreaking campaign not only provided the necessary funding for further development but also generated significant attention and interest in the emerging field of affordable and professional-grade 3D printing. The campaign showcased the potential of Formlabs’ stereolithography technology, which utilizes resin-based materials to produce high-resolution prints with exceptional detail and accuracy.

However, Formlabs faced a legal challenge when 3D Systems claimed rights to the stereolithography technology used in their printers. The lawsuit posed a significant obstacle for Formlabs, but the determined team navigated through the legal complexities and eventually settled the dispute, enabling them to move forward and continue their mission.

Formlabs’ commitment to innovation and growth also led them to secure significant investments through multiple financing rounds. This financial support allowed the company to expand its product portfolio, improve its manufacturing capabilities, and meet the growing demand in the market.

The Formlabs story exemplifies the spirit of entrepreneurship and perseverance in the face of challenges. It highlights the power of a groundbreaking idea, coupled with strategic funding and legal resolutions, to create a 3D printing powerhouse that continues to push the boundaries of what’s possible.

Formlabs’ Product Line

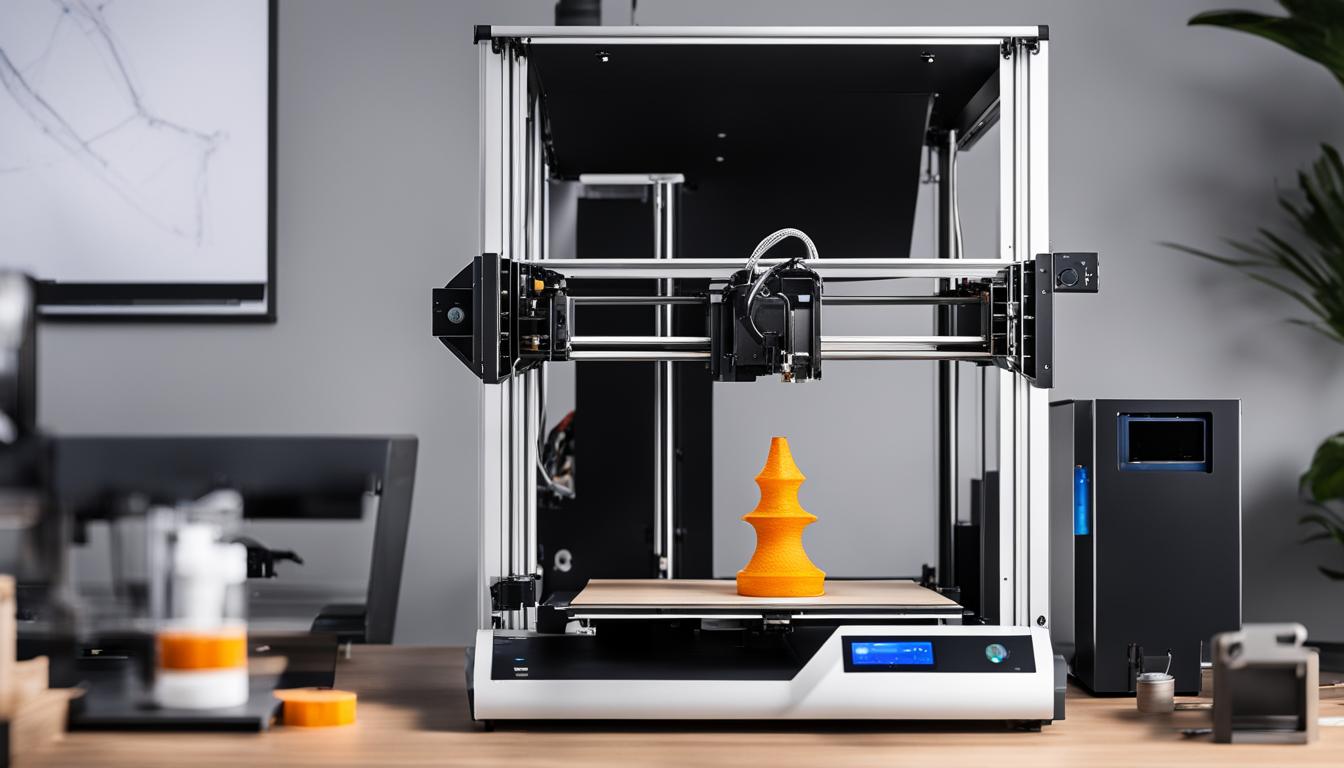

Formlabs offers a range of 3D printers that cater to both industrial and professional applications. With their advanced technology and innovative design, these printers have gained recognition in the industry for their high-quality prints and user-friendly features. Let’s take a closer look at the different models in Formlabs’ product line:

1. Form 1

The Form 1 is one of Formlabs’ early models, known for its affordability and ease of use. It utilizes stereolithography technology to create precise and detailed prints, making it an excellent choice for professionals and hobbyists.

2. Form 2

The Form 2 builds upon the success of its predecessor, offering improved performance and features. It is equipped with advanced stereolithography technology, allowing for even higher quality prints with smoother surfaces and finer details.

3. Form 3

The Form 3 takes 3D printing to the next level with its innovative Low Force Stereolithography (LFS) technology. This technology enables faster print times while maintaining exceptional accuracy and surface finish. The Form 3 is ideal for those who require professional-grade prints with minimal effort.

4. Fuse 1

For industrial applications, Formlabs offers the Fuse 1, a selective laser sintering (SLS) 3D printer. The Fuse 1 allows for the production of complex designs using a wide range of materials, making it a valuable tool for engineers, architects, and other professionals.

Formlabs’ printers are renowned for their ability to produce high-quality prints, affordability, and ease of use. These printers are suitable for a wide range of industries, including product design, manufacturing, healthcare, and more.

Formlabs’ Additional Products and Services

In addition to their cutting-edge 3D printers, Formlabs offers a range of complementary products and services that are designed to enhance the overall 3D printing workflow and deliver exceptional results. These additional offerings include:

Form Wash

The Form Wash is a post-processing device that automates the cleaning process of printed models. It utilizes ultrasonic technology to thoroughly remove uncured resin, ensuring a pristine surface finish. With customizable wash settings, users can easily adjust the wash duration and agitation to suit their specific needs. The Form Wash streamlines the post-production steps, saving time and effort.

Form Cure

The Form Cure is a vital component of the post-processing workflow, providing precise control over the curing process. Equipped with 405nm light and temperature control, it ensures thorough and efficient curing of prints. The Form Cure boasts a user-friendly interface, allowing users to easily select the appropriate curing settings based on the resin they’re using. This device guarantees consistent and optimal curing, resulting in strong, durable prints.

PreForm Software

PreForm is Formlabs’ powerful software package that simplifies the process of preparing 3D models for printing. It offers a suite of intuitive features that enable users to optimize their designs, generate supports, and efficiently manage print settings. With its user-friendly interface, PreForm empowers users to achieve exceptional print quality and precision. It supports various file formats and provides real-time print updates, making it an essential tool for streamlined 3D printing workflows.

This comprehensive suite of products and services provided by Formlabs enables users to unlock the full potential of customizable 3D printing. Whether it’s automating cleaning and curing or preparing models with precision, Form Wash, Form Cure, and PreForm Software contribute to a seamless and efficient 3D printing experience, ultimately resulting in high-quality, professional-grade prints.

| Product | Key Features |

|---|---|

| Form Wash |

|

| Form Cure |

|

| PreForm Software |

|

Formlabs’ Impact on Medical Industry

During the COVID-19 pandemic, Formlabs played a crucial role in addressing the global shortage of essential medical supplies. Leveraging their advanced 3D printing technology, Formlabs developed and produced 3D printed nasopharyngeal swabs using biocompatible resins. This innovative approach allowed for the rapid production of high-quality swabs, providing healthcare professionals with a reliable tool for COVID-19 testing.

The nasopharyngeal swabs produced by Formlabs were designed to be comfortable for patients while ensuring accurate sample collection. The biocompatible resins used in the printing process ensured that the swabs were safe and reliable for medical use. This initiative not only helped meet the increasing demand for testing supplies but also highlighted the potential of 3D printing technology in addressing healthcare challenges during emergencies.

Formlabs’ impact extended beyond the COVID-19 pandemic. Apart from producing nasopharyngeal swabs, the company has also made significant contributions to the dental industry. Recognizing the specific needs and requirements of dental professionals, Formlabs developed specialized printers and materials that revolutionized digital dentistry.

The dental industry has witnessed a remarkable transformation with the introduction of Formlabs’ 3D printing solutions. Dental laboratories and practices can now produce highly accurate dental models, surgical guides, and orthodontic aligners with ease and efficiency. The biocompatible materials used in Formlabs’ printers ensure the production of dental devices that meet the strict standards of the industry.

Formlabs’ commitment to innovation and their extensive expertise in 3D printing technology have expanded possibilities in the medical field. From addressing immediate healthcare needs to delivering customized solutions for dental professionals, Formlabs continues to drive advancements and contribute to the evolution of the healthcare industry.

Benefits of Formlabs’ Impact on Medical Industry:

- Rapid production of nasopharyngeal swabs during the COVID-19 pandemic

- Utilizing biocompatible resins for safe and reliable medical tools

- Revolutionizing the dental industry with specialized printers and materials

- Improving accuracy and efficiency in producing dental models, surgical guides, and orthodontic aligners

- Driving innovation and expanding possibilities in the healthcare sector

Formlabs’ Recognition and Achievements

Formlabs has garnered widespread recognition and achieved remarkable milestones in the 3D printing industry. Their dedication to innovation and excellence has been acknowledged through industry accolades and the inclusion of their story in the documentary “Print the Legend.”

The documentary “Print the Legend” delves into the narrative of influential companies within the desktop 3D printer industry, including Formlabs. It provides a deep insight into Formlabs’ profound contributions and remarkable success in revolutionizing the field of 3D printing.

Formlabs’ products have consistently received accolades and awards, testifying to their exceptional performance, cutting-edge technology, and significant impact on the industry. The company’s commitment to pushing the boundaries of what is possible in the 3D printing realm has been widely acknowledged and highly regarded.

Formlabs’ recognition and achievements validate their position as a leading player in the 3D printing industry. Their innovative solutions and dedication to delivering high-quality products have set them apart and earned the admiration and respect of peers and customers alike.

Future Developments and Expansion

Formlabs, a pioneer in the field of 3D printing technology, is continuously pushing the boundaries of innovation with its future developments and expansion plans. The company has recently announced the launch of new printer models, namely Form 3+ and Form 3B+, which are set to revolutionize the industry even further.

These new printers boast advanced LPU/Laser stability, ensuring precise and consistent printing results. The improved build chamber heating and monitoring system guarantees optimal print conditions, resulting in high-quality output. Additionally, Formlabs has introduced a new build platform that enhances part removal, streamlining the post-processing workflow for a more efficient user experience.

With these groundbreaking advancements, Formlabs aims to meet the evolving needs of its customers and maintain its status as a leading 3D printing solution provider. Their commitment to incorporating cutting-edge technology into their products reflects their dedication to delivering the highest quality and performance.

As the company continues to expand its product line and improve upon existing technologies, Formlabs is poised to shape the future of 3D printing. Through constant innovation and a customer-centric approach, they are revolutionizing a wide range of industries, from healthcare and manufacturing to design and architecture. Formlabs is at the forefront of the 3D printing revolution, enabling businesses and individuals alike to bring their ideas to life.