Machining metal is a process of cutting and shaping metal into a desired shape or form. It is a subtractive manufacturing process, meaning that material is removed from the workpiece to create the desired shape. The most common methods of machining metal include milling, turning, drilling, grinding, and sawing.

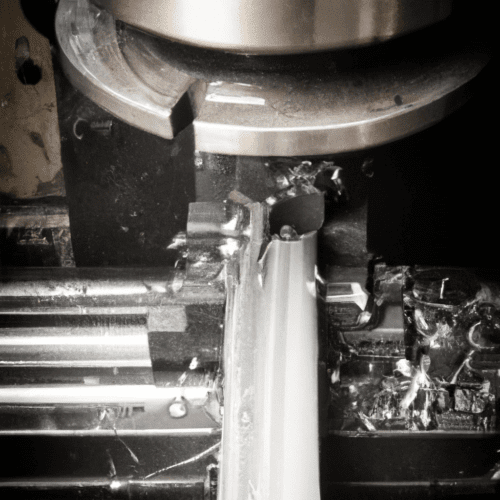

Milling is a process that uses a rotating cutting tool to remove material from the workpiece. The cutting tool is usually a milling cutter, which is a multi-point cutting tool that has several cutting edges. The cutting tool is moved along the surface of the workpiece in a linear or rotary motion, and the material is removed from the workpiece in the form of chips.

Turning is a process that uses a single-point cutting tool to remove material from the workpiece. The cutting tool is usually a lathe tool, which is a single-point cutting tool that has a cutting edge at the end. The cutting tool is moved along the surface of the workpiece in a linear or rotary motion, and the material is removed from the workpiece in the form of chips.

Drilling is a process that uses a rotating cutting tool to create a hole in the workpiece. The cutting tool is usually a drill bit, which is a multi-point cutting tool that has several cutting edges. The cutting tool is moved along the surface of the workpiece in a linear or rotary motion, and the material is removed from the workpiece in the form of chips.

Grinding is a process that uses an abrasive wheel to remove material from the workpiece. The abrasive wheel is usually a grinding wheel, which is a multi-point cutting tool that has several cutting edges. The abrasive wheel is moved along the surface of the workpiece in a linear or rotary motion, and the material is removed from the workpiece in the form of chips.

Sawing is a process that uses a saw blade to cut material from the workpiece. The saw blade is usually a band saw blade, which is a multi-point cutting tool that has several cutting edges. The saw blade is moved along the surface of the workpiece in a

What does it mean to machine a metal?

Machining metal is the process of cutting, shaping, and forming metal into a desired shape or size. It is a process that involves the use of specialized tools and machines to cut, shape, and form metal into a desired shape or size. The process of machining metal involves the use of cutting tools such as drills, milling cutters, and lathes, as well as other specialized tools such as grinding wheels, taps, and reamers. The process of machining metal also involves the use of heat and pressure to shape the metal into the desired shape or size.

The process of machining metal is used in a variety of industries, including automotive, aerospace, and medical. It is used to create components for machines, tools, and other products. It is also used to create custom parts for specific applications.

The process of machining metal involves the use of a variety of techniques, including turning, milling, drilling, grinding, and tapping. Each of these techniques is used to create a specific shape or size. The process of machining metal also involves the use of heat and pressure to shape the metal into the desired shape or size.

The process of machining metal is a complex process that requires a great deal of skill and precision. It is important to use the right tools and techniques to ensure that the metal is machined correctly and safely. It is also important to use the right materials and techniques to ensure that the metal is machined to the desired shape or size.

How is steel machined?

Steel machining is the process of cutting, drilling, grinding, and shaping metal components using specialized tools and machinery. It is a highly precise and intricate process that requires a great deal of skill and experience. The process begins with the selection of the right type of steel for the job. Different types of steel have different properties and require different machining techniques. Once the right type of steel is chosen, the machining process begins.

The first step in steel machining is to create a blueprint or design for the part that needs to be machined. This blueprint will include the dimensions, tolerances, and other specifications that need to be met. Once the blueprint is created, the machinist will use a variety of tools and machines to cut, drill, grind, and shape the steel into the desired shape. This includes the use of lathes, milling machines, drill presses, and other specialized tools.

The machinist will then use a variety of cutting tools to cut the steel into the desired shape. These tools include end mills, reamers, taps, and other specialized tools. The machinist will also use grinding tools to smooth out the edges of the steel and create a more precise finish.

Once the machining process is complete, the machinist will inspect the part to ensure that it meets the specifications outlined in the blueprint. If any adjustments need to be made, the machinist will make them and then the part is ready for use.

Steel machining is a complex and precise process that requires a great deal of skill and experience. It is important to choose the right type of steel for the job and to use the right tools and machines to ensure that the part is machined correctly. With the right tools and techniques, steel machining can produce high-quality parts that are precise and durable.

What metal is easy to machine?

Aluminum is one of the most popular metals that is easy to machine. It is lightweight, corrosion-resistant, and has a relatively low melting point, making it easy to shape and form. Aluminum is also relatively soft, which makes it easier to cut and shape than other metals. Additionally, aluminum is non-magnetic and non-sparking, making it a great choice for machining in hazardous environments. Aluminum is also relatively inexpensive, making it a great choice for machining projects on a budget.

Aluminum is not the only metal that is easy to machine. Copper and brass are also relatively soft metals that are easy to shape and form. Copper is also corrosion-resistant and non-magnetic, making it a great choice for machining in hazardous environments. Brass is also relatively inexpensive and is often used for decorative machining projects.

Stainless steel is another metal that is easy to machine. It is corrosion-resistant and non-magnetic, making it a great choice for machining in hazardous environments. Stainless steel is also relatively strong and durable, making it a great choice for machining projects that require strength and durability.

In conclusion, aluminum, copper, brass, and stainless steel are all metals that are easy to machine. Each metal has its own unique properties that make it a great choice for different machining projects. It is important to consider the specific requirements of the project before selecting a metal for machining.

Is steel easy to machine?

Steel is a relatively easy material to machine, as it is strong and durable, yet malleable enough to be cut and shaped into a variety of forms. Steel is also relatively inexpensive, making it a popular choice for machining. Steel is often machined using a variety of tools, such as drills, lathes, milling machines, and saws. The hardness of steel can vary depending on the type of steel, so it is important to select the right type of steel for the job. Steel can also be machined using a variety of techniques, such as turning, drilling, milling, and grinding. The machining process can be time consuming, but the end result is usually a high-quality product. Steel is also relatively easy to weld, making it a popular choice for fabrication projects. Steel is also resistant to corrosion, making it a great choice for outdoor applications. Overall, steel is a great choice for machining, as it is strong, durable, and relatively easy to work with.

How do I get into machining?

Getting into machining can be a rewarding and challenging career path. To get started, you will need to have a basic understanding of the tools and processes involved in machining. You should also have a good understanding of mathematics, as this is a key component of machining.

The first step to getting into machining is to gain some experience. You can do this by taking classes at a local college or technical school, or by taking an apprenticeship with a machinist. This will give you the opportunity to learn the basics of machining and get hands-on experience. You can also look for internships or volunteer positions at local machine shops to gain more experience.

Once you have some experience, you can start looking for a job in machining. You can look for job postings online or in newspapers, or you can contact local machine shops to inquire about job openings. You may also want to consider joining a trade organization, such as the National Tooling and Machining Association, to network with other machinists and learn more about the industry.

When applying for a job in machining, you will need to demonstrate your knowledge and skills. You should be prepared to show your experience and qualifications, as well as any certifications you may have. You may also need to take a written or practical test to demonstrate your knowledge and skills.

Once you have been hired, you will need to continue to learn and develop your skills. You can do this by taking classes, attending seminars, or reading books and articles about machining. You should also take advantage of any training opportunities offered by your employer.

Finally, you should stay up to date on the latest trends and technologies in machining. This will help you stay competitive and ensure that you are able to keep up with the changing demands of the industry. With the right knowledge and experience, you can become a successful machinist and enjoy a rewarding career.

What is the principle of machining?

The principle of machining is the process of removing material from a workpiece to create a desired shape or form. This is done by using a variety of tools and machines, such as lathes, milling machines, and grinders. The process of machining involves cutting, drilling, grinding, and other operations to shape the workpiece. The tools used in machining are designed to remove material from the workpiece in a precise and controlled manner.

The principle of machining is based on the idea that the material being removed is not wasted, but instead is used to create a desired shape or form. This is done by using a variety of tools and machines to cut, drill, grind, and shape the workpiece. The tools used in machining are designed to remove material from the workpiece in a precise and controlled manner. The process of machining is used in a variety of industries, including automotive, aerospace, and medical.

The principle of machining is based on the idea that the material being removed is not wasted, but instead is used to create a desired shape or form. This is done by using a variety of tools and machines to cut, drill, grind, and shape the workpiece. The tools used in machining are designed to remove material from the workpiece in a precise and controlled manner. The process of machining is used in a variety of industries, including automotive, aerospace, and medical.

The process of machining is used to create a variety of shapes and forms, including complex shapes and intricate details. The process of machining is also used to create components with precise dimensions and tolerances. The process of machining is used to create components with a high degree of accuracy and repeatability.

The principle of machining is based on the idea that the material being removed is not wasted, but instead is used to create a desired shape or form. This is done by using a variety of tools and machines to cut, drill, grind, and shape the workpiece. The tools used in machining are designed to remove material from the workpiece in a precise and controlled manner. The process of machining is used in a variety of industries, including automotive

What are metal works and machine?

Metal works and machine are a type of engineering that involves the use of metal and other materials to create a variety of products. Metal works and machine involve the use of tools and machines to shape, cut, and form metal into a desired shape or product. This type of engineering is used in a variety of industries, including automotive, aerospace, construction, and manufacturing.

Metal works and machine involve the use of a variety of tools and machines, such as lathes, milling machines, drill presses, and grinders. These tools are used to shape, cut, and form metal into a desired shape or product. The tools used in metal works and machine are designed to be precise and accurate, allowing for the creation of complex and intricate products.

Metal works and machine also involve the use of welding and soldering techniques to join metal pieces together. Welding and soldering are used to create strong and durable connections between metal pieces. This type of engineering is also used to create custom parts and components for a variety of products.

Metal works and machine also involve the use of finishing techniques, such as grinding, polishing, and painting. These techniques are used to give metal products a desired finish and to protect them from corrosion and wear.

Overall, metal works and machine is a type of engineering that involves the use of tools and machines to shape, cut, and form metal into a desired shape or product. This type of engineering is used in a variety of industries, and involves the use of welding and soldering techniques, as well as finishing techniques, to create custom parts and components.

What is metal cutting machine?

A metal cutting machine is a machine tool used to cut metal into various shapes and sizes. It is typically used in industrial settings to create parts for machines, vehicles, and other products. Metal cutting machines can be powered by electricity, hydraulics, or pneumatics, and can be manual or automated. Manual machines are operated by hand, while automated machines are operated by a computer-controlled system. Metal cutting machines can be used to cut a variety of metals, including steel, aluminum, brass, copper, and titanium. The type of metal cutting machine used depends on the type of metal being cut, the size and shape of the part being cut, and the desired accuracy and speed of the cut. Common types of metal cutting machines include saws, lathes, milling machines, and laser cutters. Each type of machine has its own advantages and disadvantages, and the type of machine used will depend on the specific application.