Laser cutting is highly accurate, with repeatability of up to ±0.02mm. Laser cutters are capable of cutting with extremely high precision, and can cut complex shapes with intricate detail. The accuracy of the cutting process is largely dependent on the type of laser being used, the material being cut, the thickness of the material, and the quality of the optics. The accuracy of laser cutting is further improved when combined with computer numerical control (CNC) technology. In summary, laser cutting is an extremely accurate process that can deliver high precision, complex shapes with outstanding results.

The Basics of Laser Cutting: What Is It and How Is It Used?

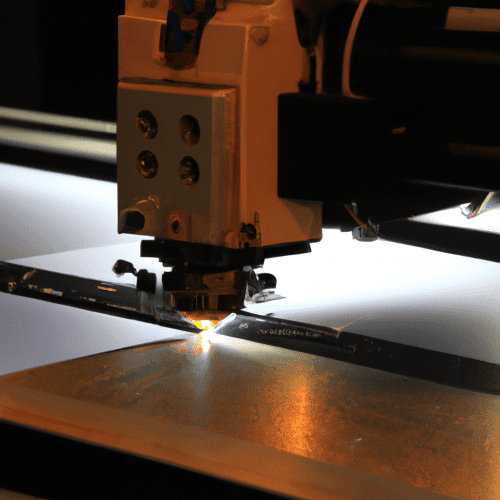

Laser cutting is a highly precise and accurate method for cutting and engraving materials such as wood, plastics, metals, and other composites. It is a process in which a focused laser beam is used to cut or engrave the material. This process uses a computer-controlled laser beam which is focused into a very small spot, allowing for very precise and intricate cuts without the need for manual intervention. The laser cutting process begins by creating a digital model of the shape or design that needs to be cut. This is done using a CAD (Computer Aided Design) program which creates a vector file. This vector file is then transferred to the laser cutting machine.

The laser cutting machine then focuses a beam of light onto the material, which is used to cut or engrave the desired shape or design. Depending on the material being cut, different laser power levels, speeds, and focal lengths may be used. Laser cutting is used in a variety of industries, ranging from aerospace to automotive to medical device manufacturing. It is often used for creating complex shapes or intricate designs that would otherwise be difficult or impossible to achieve with traditional cutting methods. Additionally, laser cutting is a very fast and efficient process, and it does not require any manual labor, allowing for highly accurate and repeatable results with minimal waste. Laser cutting is an invaluable tool for many applications, from prototyping and small scale production to industrial manufacturing. It is a precise and highly efficient method that can be used to create intricate shapes and designs with minimal effort.

Examining the Accuracy of Laser Cutting: What You Need to Know

Laser cutting is an extremely precise and cost-effective method of fabricating materials. However, to ensure accuracy and quality, it is important to know what factors to consider and what steps to take to guarantee a successful outcome. When it comes to accuracy in laser cutting, the quality of the cutting equipment is important. A laser beam needs to be of a higher power in order to cut through thicker materials. Be sure to look for lasers with a high power rating if you are cutting thicker materials. Additionally, the quality of the optics used to focus the laser beam must be taken into consideration. Low-quality optics can lead to material being cut inaccurately. Another factor that affects accuracy is the positioning of the material. The material must be placed in the exact spot desired before the laser beam is applied. If the material is not properly positioned, it will be cut inaccurately. Additionally, the material must be held securely and precisely in place as the laser beam is applied. The speed at which the laser beam is applied can also affect accuracy.

If the laser beam is applied too quickly, the material may not be cut properly. Conversely, if the laser beam is applied too slowly, the material may be cut inaccurately due to heat buildup. Finally, the programming of the laser cutting machine should be checked to ensure accuracy. The programming should be written in a way that takes into account the material, the desired shape, and the desired accuracy. If the programming is incorrect, the laser cutting machine may not be able to cut the material accurately. These are just a few of the factors to consider when examining the accuracy of laser cutting. By taking into account the quality of the laser, the positioning of the material, the speed of the laser beam, and the programming of the machine, you can ensure that your laser cutting project is completed with accuracy and precision.

Exploring the Benefits of Laser Cutting and Its Precision

Laser cutting is an increasingly popular manufacturing technique that is being used in a variety of industries today. Its precision and accuracy make it a preferred choice among engineers and manufacturers when it comes to cutting and engraving materials. Laser cutting uses a focused beam of light to cut through materials, allowing for precise cuts and intricate designs. The primary benefit of laser cutting is its precision. Laser cutting technology is capable of creating incredibly accurate and consistent shapes and sizes. It is so precise that it can create parts with dimensions that are as small as 0.001 inches (0.0254 mm). This accuracy allows manufacturers to create parts that are closely matched with the original design and specifications. Another benefit of laser cutting is its speed. Laser cutting machines can process large numbers of parts quickly and efficiently. This allows for faster production times and higher throughput for larger projects.

Additionally, laser cutting machines can be programmed to repeat the same cut multiple times, increasing the speed and efficiency of the process. Laser cutting also offers improved safety and cost savings. It does not require manual labor, which can reduce the risk of accidents. Additionally, laser cutting machines can be programmed to cut multiple materials at once, reducing setup time and labor costs. This allows manufacturers to save money on labor costs and increase their overall production efficiency. Finally, laser cutting provides superior quality results. The laser beam is capable of creating very smooth edges and precise shapes, which can reduce post-processing time and improve the quality of the finished product. In conclusion, laser cutting offers a variety of benefits for manufacturers and engineers. Its precision and speed make it an ideal choice for many projects, and its cost savings and improved safety make it an attractive option. Laser cutting is sure to remain a popular choice in the years to come.

Analyzing the Different Types of Laser Cutting and Their Capabilities

Laser cutting is a versatile and precise manufacturing process that uses a focused beam of light to cut through materials. Depending on the type of laser used and the material being cut, the process can offer a wide range of capabilities to businesses. CO2 Lasers are the most common type of laser cutter and are ideal for cutting and engraving non-metallic materials such as wood, plastic, paper, and fabrics. These lasers use a gas mixture of carbon dioxide, nitrogen, and helium to create a focused beam of light that can cut through materials up to 1.5″ thick. CO2 lasers are fast and accurate with a repeatability of up to 0.002”, making them a great choice for creating intricate designs and shapes. Fiber Lasers are similar to CO2 lasers but use a fiber-optic cable to transmit the laser beam. This type of laser is faster and more efficient than a CO2 laser, and can cut materials up to 0.75” thick. Fiber lasers are also well-suited for engraving and marking metals such as stainless steel, aluminum, and brass.

Excimer Lasers are powerful ultraviolet lasers that are used to cut and etch hard, durable materials such as glass, ceramics, and metals. These lasers are incredibly precise and can cut intricate shapes with a repeatability of up to 0.0005”. Excimer lasers are also capable of cutting materials up to 1” thick. Diode Lasers are the most powerful type of laser cutter, capable of cutting through almost any material up to 6” thick. Diode lasers are extremely fast and accurate, with a repeatability of up to 0.001”, and are perfect for cutting and engraving metals such as steel, aluminum, and brass. No matter the type of material being cut or the desired outcome, laser cutting offers a wide range of capabilities that can meet the needs of any business. From intricate engravings to thick metal cuts, laser cutting offers businesses the precision and accuracy they need to produce quality products.

Cost Comparison of Different Laser Cutting Techniques and Their Accuracy

Laser cutting is a highly precise and versatile manufacturing technique used to create custom products and components. It is used in a variety of industries, from automotive and aerospace to electronics and medical device production. Laser cutting offers several distinct advantages over traditional machining processes, including faster production times, higher accuracy, and better repeatability. Depending on the material being cut and the desired level of precision, there are several different laser cutting techniques available. Each technique has its own unique cost and accuracy profile. CO2 laser cutting is the most common laser cutting technique. It is relatively inexpensive, and its accuracy is typically within 0.015mm. This technique is suitable for cutting a wide variety of materials, including wood, plastics, composites, and mild steel. It can also be used to mark, engrave, or etch surfaces. Fiber laser cutting is a newer technology that has become increasingly popular in recent years. It offers higher speeds and greater accuracy than CO2 laser cutting, with accuracy up to 0.005mm.

This technique is suitable for cutting a wide variety of metals, including stainless steel, aluminum, and titanium. The cost of fiber laser cutting is higher than CO2 laser cutting due to the higher initial investment in the equipment. Ultrashort pulse laser cutting is a specialized form of laser cutting that uses ultrashort laser pulses to cut materials with extreme precision. This technique is capable of achieving accuracy up to 0.001mm, and it is suitable for cutting thin materials such as foils and foams. The cost of ultrashort pulse laser cutting is higher than CO2 and fiber laser cutting due to the specialized equipment required. When selecting a laser cutting technique, it is important to consider cost and accuracy. CO2 laser cutting is the most cost-effective option and is suitable for most applications. Fiber laser cutting is more expensive but offers higher speeds and greater accuracy. Ultrashort pulse laser cutting offers the highest level of accuracy but is the most expensive option.