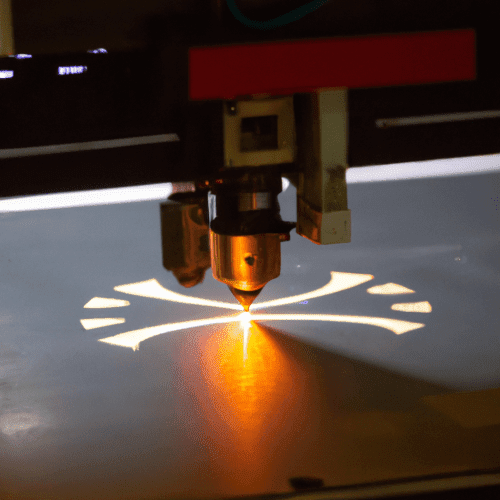

Laser cutting is a process that uses a laser beam to cut materials such as metal, wood, plastic, and more. The thickness of the material that can be cut depends on the type of laser used, the material being cut, and the power of the laser. Generally, laser cutting can cut materials up to a thickness of 1/4 inch (6.35 mm). However, some lasers can cut materials up to a thickness of 1 inch (25.4 mm).

The type of laser used for cutting is an important factor in determining the maximum thickness of the material that can be cut. CO2 lasers are the most common type of laser used for cutting and can cut materials up to a thickness of 1/4 inch (6.35 mm). Fiber lasers are more powerful than CO2 lasers and can cut materials up to a thickness of 1 inch (25.4 mm).

The material being cut also affects the maximum thickness that can be cut. For example, metals such as aluminum and stainless steel can be cut up to a thickness of 1/4 inch (6.35 mm) with a CO2 laser, while thicker metals such as mild steel can be cut up to a thickness of 1/2 inch (12.7 mm). Wood and plastic can be cut up to a thickness of 1/4 inch (6.35 mm) with a CO2 laser.

The power of the laser is also an important factor in determining the maximum thickness of the material that can be cut. Higher powered lasers can cut thicker materials than lower powered lasers. For example, a 100 watt laser can cut materials up to a thickness of 1/2 inch (12.7 mm), while a 50 watt laser can only cut materials up to a thickness of 1/4 inch (6.35 mm).

In conclusion, the maximum thickness of the material that can be cut with a laser depends on the type of laser used, the material being cut, and the power of the laser. Generally, laser cutting can cut materials up to a thickness of 1/4 inch (6.35 mm), but some lasers can cut materials up to a thickness of 1 inch (25.4 mm).

What is the maximum thickness laser can cut?

Laser cutting is a process that uses a laser beam to cut materials such as metal, plastic, wood, and other materials. The maximum thickness that a laser can cut depends on the type of laser used, the material being cut, and the power of the laser. Generally, a CO2 laser can cut up to 1 inch of material, while a fiber laser can cut up to 2 inches of material. However, the maximum thickness that a laser can cut can vary depending on the material being cut, the power of the laser, and the type of laser used. For example, a CO2 laser with a higher power can cut thicker materials than a CO2 laser with a lower power. Additionally, some materials, such as aluminum, can be cut with a higher power laser than other materials, such as wood. The maximum thickness that a laser can cut also depends on the type of laser used. For example, a CO2 laser is typically used to cut thicker materials than a fiber laser.

How thick can a laser be?

The thickness of a laser beam is determined by the wavelength of the light used to create it. The shorter the wavelength, the thinner the beam. The most common lasers used in industry are gas lasers, which use a mixture of gases to create a beam of light. These lasers typically have a wavelength of around 0.5 micrometers, which is about the same size as a human hair. This means that the beam of light created by these lasers is very thin, usually only a few micrometers in diameter. However, there are other types of lasers that can produce much thinner beams. For example, some solid-state lasers can produce beams with a diameter of only a few nanometers, which is about a thousand times thinner than a human hair. So, in theory, a laser beam can be as thin as a few nanometers, although this is not typically achievable in practice.

How thick can a 6000 watt laser cut?

The thickness of material that a 6000 watt laser can cut depends on a variety of factors, including the type of material, the type of laser, and the laser’s power output. Generally speaking, a 6000 watt laser can cut through materials up to 1 inch thick, depending on the material. For example, a 6000 watt laser can cut through mild steel up to 1 inch thick, while aluminum can be cut up to 0.5 inches thick. The laser’s power output also affects the thickness of the material it can cut. For example, a 6000 watt laser with a higher power output can cut through thicker materials than a laser with a lower power output. Additionally, the type of laser used can also affect the thickness of material it can cut. For example, a CO2 laser is better suited for cutting thicker materials than a fiber laser.

In conclusion, the thickness of material that a 6000 watt laser can cut depends on a variety of factors, including the type of material, the type of laser, and the laser’s power output.

How thick can a 12kW laser cut?

The thickness of material that a 12kW laser can cut depends on a variety of factors, including the type of material, the type of laser, and the laser’s power settings. Generally speaking, a 12kW laser can cut through materials up to 1 inch thick, depending on the material and the laser’s settings. For example, a 12kW laser can cut through mild steel up to 1 inch thick, while aluminum can be cut up to 0.5 inches thick. The laser’s power settings can also affect the thickness of material that can be cut. For example, if the laser is set to a lower power setting, it may be able to cut through thicker materials than if it is set to a higher power setting. Additionally, the type of laser can also affect the thickness of material that can be cut. For example, a CO2 laser is typically better suited for cutting thicker materials than a fiber laser. Ultimately, the thickness of material that a 12kW laser can cut will depend on the type of material, the type of laser, and the laser’s power settings.

How thick can a 1000 watt laser cut?

The thickness of material that a 1000 watt laser can cut depends on a variety of factors, including the type of material, the type of laser, and the laser’s power output. Generally speaking, a 1000 watt laser can cut through materials up to 1/2 inch thick, depending on the material. For example, a 1000 watt laser can cut through steel up to 1/4 inch thick, aluminum up to 1/2 inch thick, and stainless steel up to 1/8 inch thick. However, the thickness of material that a 1000 watt laser can cut can vary depending on the type of laser and the power output. For example, a CO2 laser with a power output of 1000 watts can cut through steel up to 1/2 inch thick, aluminum up to 3/4 inch thick, and stainless steel up to 1/4 inch thick. Additionally, the thickness of material that a 1000 watt laser can cut can also be affected by the type of laser optics used. For example, a laser with a higher numerical aperture (NA) can cut through thicker materials than a laser with a lower NA.

How thick can a 10kw laser cut?

The thickness of material that a 10kW laser can cut depends on a variety of factors, including the type of material, the type of laser, and the laser’s power settings. Generally speaking, a 10kW laser can cut through materials up to 1 inch thick, depending on the material. For example, a 10kW laser can cut through mild steel up to 1 inch thick, stainless steel up to 0.75 inches thick, and aluminum up to 0.5 inches thick. However, these thicknesses can vary depending on the laser’s power settings and the type of material being cut.

For example, if the laser is set to a lower power setting, it may not be able to cut through materials as thick as it would at a higher power setting. Additionally, some materials, such as titanium, require higher power settings to cut through thicker materials. As such, the thickness of material that a 10kW laser can cut can vary depending on the material and the laser’s power settings.

How thick metal can a laser cutter cut?

Laser cutters are capable of cutting through a wide range of materials, including metal. The thickness of metal that a laser cutter can cut depends on the type of laser cutter being used, the type of metal being cut, and the power of the laser. Generally, laser cutters are capable of cutting through metal up to a thickness of 1/4 inch. However, some laser cutters are capable of cutting through thicker metal, up to 1/2 inch or even 3/4 inch. The type of metal being cut also affects the thickness that can be cut. For example, aluminum is easier to cut than steel, so a laser cutter may be able to cut thicker aluminum than steel. Additionally, the power of the laser cutter affects the thickness of metal that can be cut. Higher powered laser cutters are able to cut through thicker metal than lower powered laser cutters.

In order to determine the exact thickness of metal that a laser cutter can cut, it is best to consult the manufacturer’s specifications.

How thick can a 60W laser cut?

The thickness of material that a 60W laser can cut depends on a variety of factors, including the type of material, the type of laser, and the settings used. Generally speaking, a 60W laser can cut through a variety of materials, including wood, acrylic, and some metals. For wood, a 60W laser can cut up to 1/4 inch thick, while for acrylic, it can cut up to 1/2 inch thick. For metals, a 60W laser can cut up to 1/8 inch thick, depending on the type of metal. Additionally, the settings used can affect the thickness of material that a 60W laser can cut. For example, if the speed is increased, the thickness of material that can be cut may be reduced.

In conclusion, a 60W laser can cut through a variety of materials, with the thickness of material that can be cut depending on the type of material, the type of laser, and the settings used.

How thick can a c02 laser cut?

The thickness of material that a CO2 laser can cut depends on a variety of factors, including the power of the laser, the type of material being cut, and the speed at which the laser is moving. Generally speaking, a CO2 laser with a power of 40-200 watts can cut through materials up to 1/4 inch thick. However, if the laser is moving faster, it can cut through thicker materials. For example, a laser with a power of 40-200 watts can cut through materials up to 1/2 inch thick if it is moving at a speed of 500 inches per minute.

The type of material being cut also affects the thickness that a CO2 laser can cut. For example, a laser with a power of 40-200 watts can cut through wood up to 1/2 inch thick, but it can only cut through metal up to 1/8 inch thick. Additionally, the type of laser beam used can also affect the thickness that a CO2 laser can cut. For example, a focused beam can cut through thicker materials than a defocused beam.