Proto Labs offers fast and reliable rapid prototyping services through three core manufacturing processes: 3D printing, CNC machining, and injection molding. Their digital manufacturing approach enables production of high-quality prototype parts in as little as 1 day, with automated design analysis and real-time pricing provided within hours of CAD file upload. Proto Labs’ comprehensive capabilities include a wide range of plastic and metal materials, multiple 3D printing technologies like SLA and SLS, precision CNC machining with tight tolerances, and low-volume injection molding using aluminum tooling.

Their rapid prototyping services accelerate product development by integrating prototyping into design, testing, and validation phases. With ISO certifications and a global manufacturing network, Proto Labs offers consistent lead times, material options, and a reliable supply chain for both prototypes and production parts. Their online platform streamlines the entire process from quoting to order tracking, making Proto Labs a single, comprehensive resource for rapid prototyping and low-volume manufacturing needs.

- Proto Labs offers fast and reliable rapid prototyping services.

- They specialize in custom prototyping using injection molding, CNC machining, and additive manufacturing.

- Proto Labs’ proprietary software provides interactive quotes and design analysis.

- Their experienced engineering team provides design feedback and recommendations.

- They offer a wide range of materials and finishing options to meet project requirements.

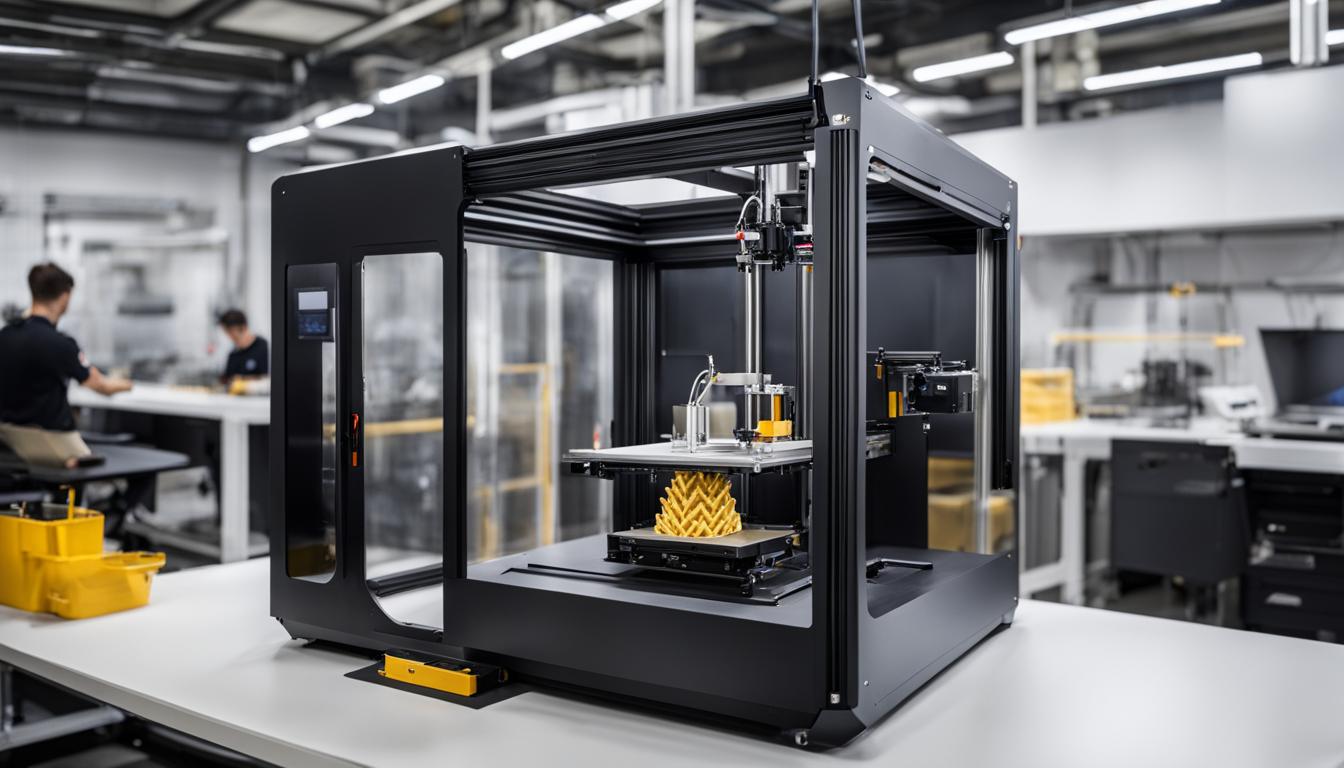

Proto Labs Additive Manufacturing

Proto Labs offers a wide range of 3D printing technologies to transform 3D files into plastic, metal, and elastomeric parts. With over 120 3D printers, they have unmatched capacity and can deliver parts within days. Their additive manufacturing processes include stereolithography (SLA), selective laser sintering (SLS), multi jet fusion (MJF), PolyJet, Carbon DLS, and more. Each technology has its own capabilities and materials, allowing customers to choose the most suitable process for their application. Proto Labs also provides post-processing options, such as custom finishing, including clear coating, painting, plating, and machining, to enhance the aesthetics or mechanical properties of the prototypes.

| 3D Printing Technologies | Materials |

|---|---|

| SLA (Stereolithography) | Resins, including ABS-like, clear, flexible, and high-temperature materials |

| SLS (Selective Laser Sintering) | Nylon and other thermoplastic powders |

| MJF (Multi Jet Fusion) | Nylon and other thermoplastic powders |

| PolyJet | Photopolymers with a wide range of material properties |

| Carbon DLS (Digital Light Synthesis) | Elastomers and tough, rigid, and high-temperature resins |

Proto Labs’ additive manufacturing processes offer versatility in material selection, allowing customers to create prototypes and functional parts with various mechanical properties. Whether it’s for visual models, functional prototypes, or end-use parts, Proto Labs’ 3D printing services enable rapid prototyping and efficient production.

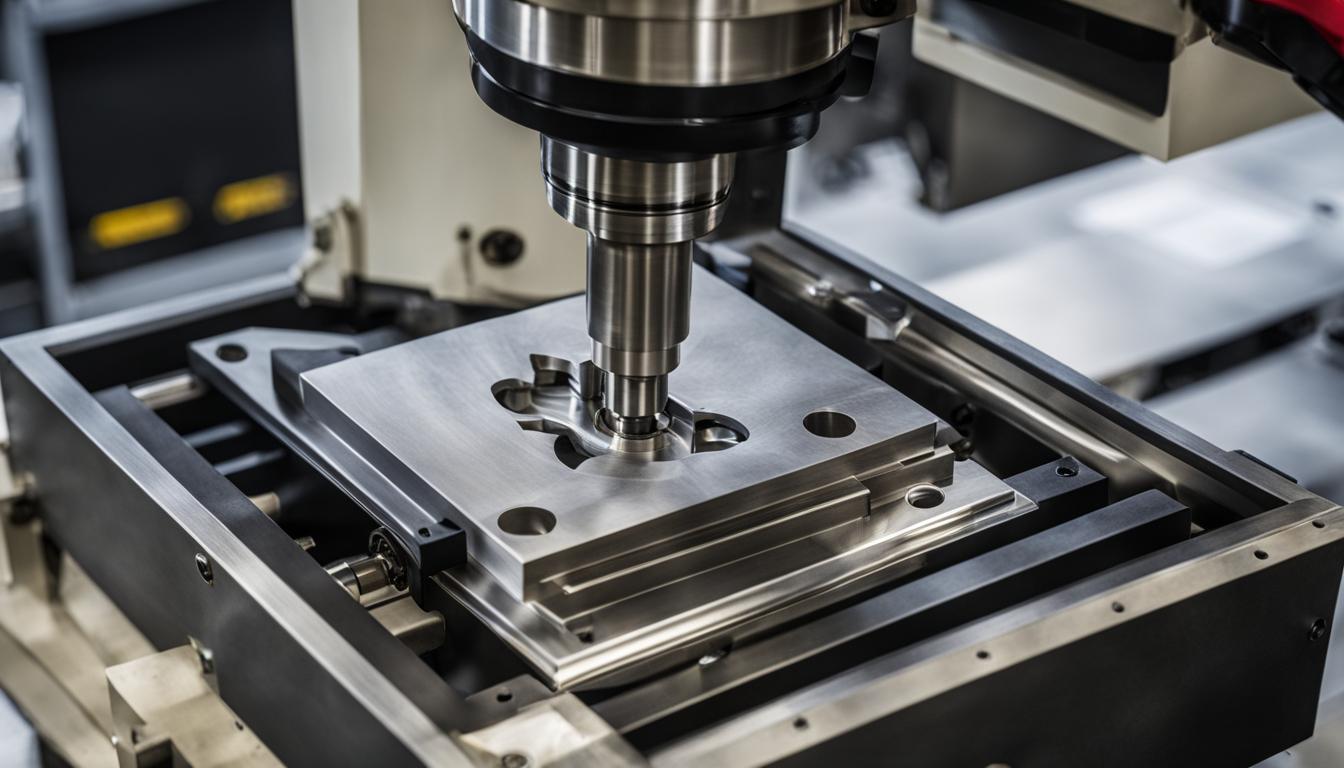

Proto Labs CNC Machining

Proto Labs offers CNC machining services for quick turnaround prototyping and production needs. With their advanced machining equipment and experienced engineering team, they provide high-quality proto parts in a timely manner. CNC machining is the ideal solution for functional testing, form and fit verification, and low-volume production.

High-Quality Proto Parts

Proto Labs utilizes state-of-the-art CNC machines to produce parts with tight tolerances, ensuring the highest level of precision and quality. Whether you need metal or plastic parts, Proto Labs can meet your design requirements with a wide range of materials available.

Quick Turnaround Prototyping

Proto Labs understands the importance of fast prototyping to accelerate the product development process. Their CNC machining capabilities enable quick turnaround times, allowing you to iterate and refine your designs efficiently.

Proto Labs’ streamlined process and automated manufacturing ensure that you receive your proto parts in the shortest time possible without compromising on quality.

https://www.youtube.com/watch?v=MyX77QwqNms

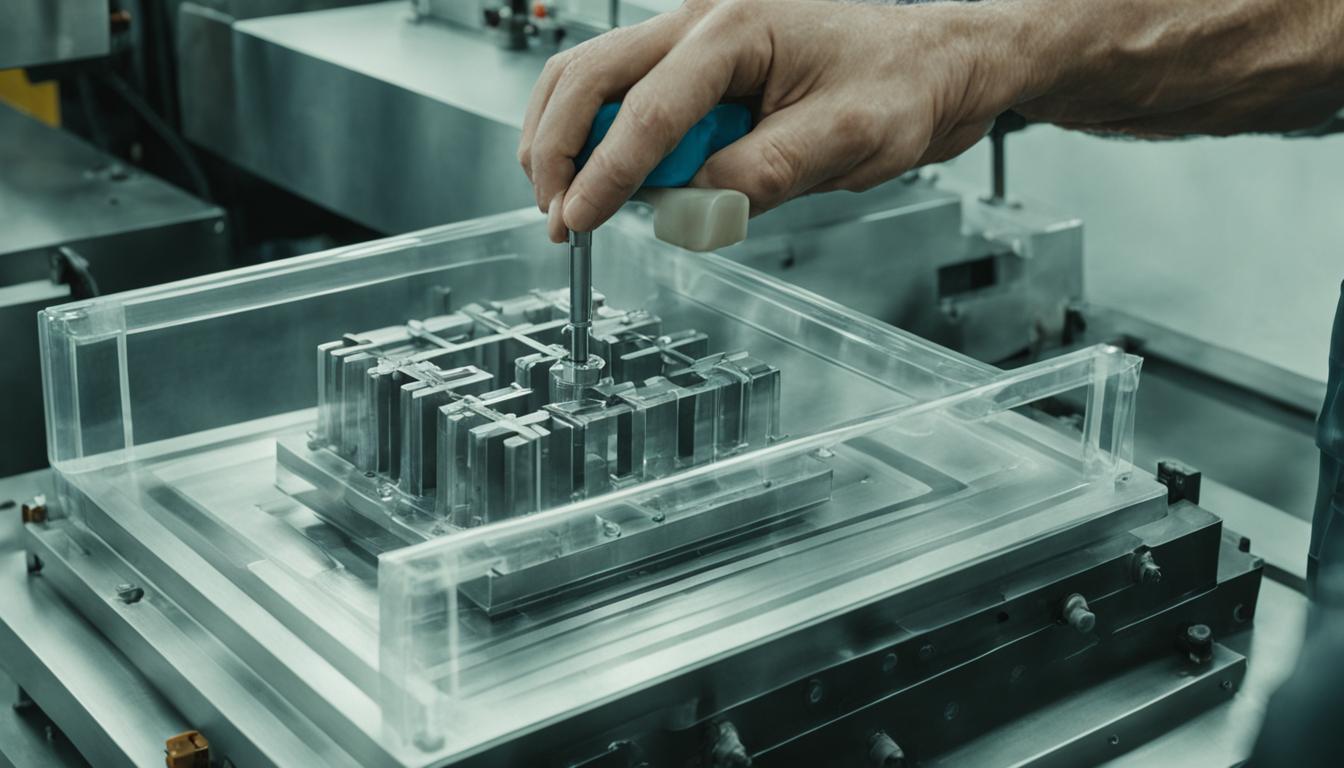

Proto Labs Injection Molding

Proto Labs offers exceptional injection molding services for the production of low to mid-volume plastic parts. With their expertise in mold building and proprietary processes, they can efficiently and quickly produce high-quality custom parts at competitive prices. Utilizing advanced software and automation, Proto Labs streamlines the injection molding process, reducing lead times and costs for customers.

Injection molding is an ideal solution for various applications and industries, including consumer products, automotive components, and medical devices. The process allows for the creation of intricate designs with close tolerances, making it suitable for complex parts. Product developers benefit from the fast turnaround time and cost-effectiveness of injection molding, enabling them to bring their prototypes and low-volume production to market quickly.

The Injection Molding Process

The injection molding process involves injecting molten plastic into a custom-designed mold, which is then cooled and solidified to form the desired shape. Proto Labs ensures the accuracy and quality of the molded parts by utilizing advanced technology and precise manufacturing processes. The high degree of automation minimizes human error and allows for consistent and reliable results.

Proto Labs offers a wide selection of materials for injection molding, including thermoplastics and elastomers. Whether the parts need to be durable, flexible, or heat-resistant, there is a suitable material available to meet the specific requirements. Proto Labs’ material selection ensures that the produced parts possess the necessary mechanical and physical properties.

With Proto Labs’ injection molding services, customers can expect:

- Fast turnaround time for prototyping and low-volume production

- Cost-effective manufacturing solutions

- High-quality, consistent parts

- Versatility in material selection

- Ability to handle intricate designs and complex geometries

The Benefits of Injection Molding

Injection molding offers numerous advantages for product development:

- High Efficiency: Injection molding allows for the simultaneous production of multiple identical parts, increasing productivity and reducing manufacturing costs.

- Design Flexibility: The process enables the creation of intricate and complex designs with precise details, providing designers with more design freedom.

- Cost-Effectiveness: Once the mold is manufactured, the cost per part decreases significantly, making it a cost-effective solution for low to mid-volume production.

- Quick Turnaround Time: Injection molding offers fast production cycles, allowing product developers to quickly iterate designs and bring products to market faster.

- Customizability: With a wide range of materials and finishes available, injection molding allows for customized parts that meet specific requirements and enhance product functionality and aesthetics.

Injection molding plays a critical role in the rapid prototyping and low-volume production process. Proto Labs’ expertise and dedication to quality ensure that customers receive high-quality injection molded parts within tight timelines, supporting their product development goals.

Proto Labs Material Selection and Finishing Options

When it comes to prototyping, choosing the right materials and finishing options is essential for achieving the desired functionality, appearance, and performance of your parts. Proto Labs offers a diverse selection of materials for both 3D printing and CNC machining processes, ensuring that you have the flexibility to meet your specific requirements.

Materials for 3D Printing

Proto Labs provides a wide range of materials for 3D printing, each with its own unique characteristics and applications. Some of the materials available include:

- ABS: A durable and versatile thermoplastic suitable for a wide range of applications.

- Polycarbonate: Known for its high impact resistance and transparency, making it ideal for functional prototypes.

- Polypropylene: Offering good chemical resistance and flexibility, suitable for snap-fit assemblies.

- Silicone: A soft and flexible material often used for prototypes that require elasticity and heat resistance.

- Nylons: Providing excellent strength and durability, commonly used for functional prototypes and end-use parts.

These are just a few examples of the materials available for 3D printing at Proto Labs. The choice of material depends on factors such as desired mechanical properties, visual appearance, and functional requirements.

Materials for CNC Machining

Proto Labs also offers a variety of materials for CNC machining, providing high-quality parts with precision and accuracy. Some of the materials you can choose from include:

- Aluminum: Lightweight and corrosion-resistant, ideal for applications where weight reduction is important.

- Stainless Steel: Known for its strength and durability, suitable for parts that require resistance to heat and chemicals.

- Titanium: Offering high strength-to-weight ratio and excellent corrosion resistance, commonly used in aerospace and medical industries.

- Cobalt Chrome: Known for its biocompatibility and resistance to wear and corrosion, often used in medical and dental applications.

These materials provide a wide range of options for CNC machining, allowing you to create prototypes with the desired mechanical properties and surface finishes.

Finishing Options

In addition to material selection, Proto Labs also offers various finishing options to enhance the appearance and properties of your prototypes. These finishing options include:

- Clear Coating: Provides a transparent and glossy finish to enhance the aesthetics of your parts.

- Painting: Allows you to add color and texture to your prototypes for visual appeal.

- Plating: Offers a metallic finish and improved corrosion resistance.

- Dyeing: Provides vibrant colors for parts made from certain materials.

- Decaling: Allows you to add logos or custom graphics to your prototypes.

- Polishing: Creates a smooth and reflective surface finish.

- Heat Treatment: Enhances the mechanical properties of certain materials.

- Custom Machining: Provides additional machining operations to achieve specific design requirements.

These finishing options give you the flexibility to customize your prototypes and meet your desired specifications, whether it’s for visual presentation or functional performance.

| Finishing Option | Description |

|---|---|

| Clear Coating | Adds a transparent and glossy finish to the parts for enhanced aesthetics. |

| Painting | Enables the addition of color and texture to the prototypes for visual appeal. |

| Plating | Offers a metallic finish and improved corrosion resistance. |

| Dyeing | Provides vibrant colors for parts made from certain materials. |

| Decaling | Allows the addition of logos or custom graphics to the prototypes. |

| Polishing | Creates a smooth and reflective surface finish. |

| Heat Treatment | Enhances the mechanical properties of certain materials. |

| Custom Machining | Provides additional machining operations to achieve specific design requirements. |

By choosing the most suitable material and finishing option, you can optimize the performance, functionality, and aesthetics of your prototypes. Proto Labs ensures that you have the tools and options needed to bring your ideas to life.

Proto Labs Customer Reviews and Ratings

Proto Labs has garnered positive feedback and exceptional ratings from its satisfied customers. With an impressive overall rating of 4.26 out of 5 based on 25 community reviews, Proto Labs proves to be a trusted and reliable partner for rapid prototyping needs.

Customers commend Proto Labs for their exceptional speed, top-notch quality, and outstanding customer service. Many reviewers specifically mention their experience with Proto Labs for CNC prototypes and rapid prototyping services. They highlight the company’s remarkable ability to deliver projects with a fast turnaround time, while also appreciating the helpfulness and professionalism of the knowledgeable customer service team.

Although occasional delays in communication are mentioned by some reviewers, the production process and the consistent quality of the parts are found to be extremely satisfactory. Based on their positive experiences, customers highly recommend Proto Labs to others who are in search of reliable rapid prototyping solutions.

Proto Labs’ commitment to customer satisfaction and the enduring partnerships they build with their clients contribute to their positive reputation within the industry. The exceptional ratings and community reviews showcase Proto Labs’ position as a leader in the rapid prototyping sector.

Customer Testimonials:

- “Proto Labs exceeded my expectations with their rapid prototyping services. The fast turnaround time and high-quality prototypes made the entire process seamless and efficient. I highly recommend them for any prototyping needs.” – John Smith

- “Having used Proto Labs for multiple projects, I am always impressed by their professionalism and attention to detail. Their customer service team is always there to assist with any inquiries, making the entire experience smooth and hassle-free.” – Sarah Davis

- “Proto Labs is my go-to company for CNC prototypes. They consistently deliver exceptional parts with remarkable precision. Their expertise and commitment to quality are truly commendable.” – Michael Johnson

Choosing the Right Rapid Prototyping Process

When it comes to rapid prototyping, selecting the appropriate process is essential to meet the specific requirements of your project. Proto Labs offers a range of prototyping processes, each with its own strengths and limitations. Understanding the differences between these processes enables you to make an informed decision and achieve optimal results for your design.

SLA vs. SLS

Two popular prototyping processes are Stereolithography (SLA) and Selective Laser Sintering (SLS). SLA is an ideal choice for detailed parts, providing high resolution and smooth surface finishes. SLS, on the other hand, is preferred for functional prototypes that require durability and intricate geometries. With SLS, you can produce parts with excellent mechanical properties and complex designs.

To help you decide between SLA and SLS, consider the specific needs of your project. If detailed aesthetics are crucial, SLA may be the better option. However, if functionality and robustness are paramount, SLS is the way to go.

SLA vs. FDM

Another comparison to consider is between SLA and Fused Deposition Modeling (FDM). SLA is known for its accuracy, making it a great choice for prototyping intricate parts with fine details. FDM, on the other hand, is commonly used for early-stage prototyping, offering quick turnaround times and cost-effective solutions.

In deciding between SLA and FDM, think about the level of detail required in your design and the time constraints of your project. If you need high precision and intricate features, SLA is recommended. Alternatively, if you prioritize speed and cost-efficiency, FDM is a suitable choice.

MJF vs. SLS

Multi Jet Fusion (MJF) and Selective Laser Sintering (SLS) are two additive manufacturing processes with distinct advantages. MJF is known for its fast production speed and produces parts with excellent mechanical properties. It is an ideal choice for applications that demand durable and high-quality prototypes. SLS, on the other hand, offers versatility and can produce functional prototypes with complex geometries and excellent surface finishes.

When deciding between MJF and SLS, consider the specific requirements of your project. If speed and mechanical strength are key factors, MJF is a great option. However, if you require intricate designs and superior surface finishes, SLS may be the better choice.

| Rapid Prototyping Process | Advantages | Limitations |

|---|---|---|

| SLA | High resolution Smooth surface finishes Ideal for detailed parts |

Limited material options Parts may be brittle |

| SLS | Durable prototypes with excellent mechanical properties Complex designs |

Less smooth surface finishes Material limitations |

| FDM | Quick turnaround times Cost-effective Early-stage prototyping |

Lower accuracy and surface finish Less ideal for intricate parts |

| MJF | Fast production speed Excellent mechanical properties |

Limited material options Less intricate details |

Proto Labs provides a helpful decision tree to guide customers in selecting the most suitable rapid prototyping process based on factors such as functionality, appearance, tolerances, and materials. By considering these factors and understanding the strengths and limitations of each process, you can make an informed choice and ensure the successful realization of your design.

Advantages of Rapid Prototyping

Rapid prototyping offers several advantages in product development. It allows for quick design iterations, enabling designers to test different concepts and make adjustments based on feedback. By using rapid prototyping processes like 3D printing and CNC machining, companies can save costs compared to traditional manufacturing methods that require tooling and setup.

Rapid prototyping also enables fast production, with parts being manufactured within a short timeframe. This speed to market can give companies a competitive edge by accelerating the product development cycle.

Rapid Design Iterations

One of the key advantages of rapid prototyping is the ability to quickly iterate on designs. With traditional manufacturing methods, making changes to a product design can be time-consuming and expensive. However, with rapid prototyping, designers can easily produce multiple iterations of a design and test them in a short period. This iterative process allows for refinement and improvement, leading to better final designs.

Cost Savings

Rapid prototyping can result in significant cost savings for companies. Traditional manufacturing methods often involve high setup costs, such as creating molds or tooling. These costs can be prohibitive for small-scale production or when making design changes. In contrast, rapid prototyping processes like 3D printing and CNC machining require minimal setup and tooling, reducing costs associated with manufacturing. Additionally, rapid prototyping eliminates the need for large-scale production runs, allowing companies to produce only the necessary quantity of parts.

Fast Production

Rapid prototyping enables fast production of parts, providing a competitive advantage in today’s fast-paced market. With traditional manufacturing methods, the production process can be lengthy, involving multiple stages and coordination. However, with rapid prototyping, parts can be manufactured within a short timeframe, often in a matter of days. This speed to market allows companies to quickly respond to customer demands, launch products faster, and gain a competitive edge over their competitors.

The Importance of Prototype Testing and Validation

Prototype testing and validation are critical components of the product development process. Designers rely on prototypes to test the form, fit, and function of their products or components. This crucial step allows them to identify any design flaws or shortcomings, make necessary modifications, and ensure that the final product meets the desired specifications.

Prototype testing encompasses various aspects, including functional testing, assembly and fit testing, and even regulatory compliance testing when applicable. By subjecting prototypes to rigorous testing procedures, companies can ensure that their products perform as intended and meet the highest quality standards.

Furthermore, market trials and user feedback provide invaluable insights into the viability of the design and help gauge market acceptance. By collecting feedback from potential customers and studying their experiences with the prototype, companies can make informed decisions about design refinements or adjustments to enhance the product’s appeal and usability.

Through thorough prototype testing and validation, companies can minimize potential issues, optimize the design, and increase the chances of a successful product launch. By investing time and resources in this crucial step, businesses can mitigate risks, uncover unknown challenges, and ultimately deliver products that exceed customer expectations.