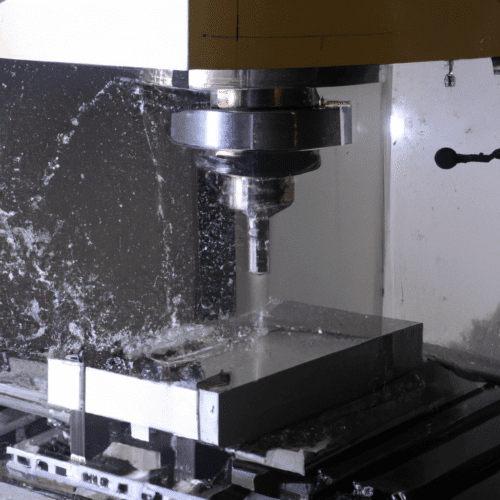

Milling is a machining process that uses a rotating cutting tool to shape and form materials such as metal and wood. There are two main types of milling operations: face milling and peripheral milling.

Face milling is a process in which the cutting tool is moved perpendicular to the surface of the material being machined. This type of milling is used to create flat surfaces on the material, as well as to create slots, grooves, and other features. The cutting tool is usually a multi-toothed end mill, which is designed to cut in a variety of directions.

Peripheral milling is a process in which the cutting tool is moved parallel to the surface of the material being machined. This type of milling is used to create curved surfaces, as well as to create slots, grooves, and other features. The cutting tool is usually a single-toothed end mill, which is designed to cut in a single direction.

What are the milling operations?

Milling operations are a category of machining processes that involve the use of rotary cutters to remove material from a workpiece in order to create a desired shape or finish. Milling operations can be divided into two general categories: face milling and peripheral milling. Face milling is used to cut flat surfaces into the workpiece, while peripheral milling is used to cut the sides of the workpiece.

The most common milling operations include end milling, slot milling, face milling, and contour milling. End milling is used to cut slots, grooves, and other features into the end of a workpiece. Slot milling is used to cut slots into the side of a workpiece. Face milling is used to cut flat surfaces into the workpiece, while contour milling is used to cut curved surfaces into the workpiece.

Other milling operations include form milling, which is used to create complex shapes, and straddle milling, which is used to cut two parallel slots in the same workpiece.

What are the operations on milling machine any one can do?

Milling machines are versatile tools used in metalworking and woodworking operations. They can be used to shape and form a variety of materials, including metal, wood, plastic, and composites. With the right tools and knowledge, milling machines can be used to perform a variety of operations, including drilling, boring, reaming, tapping, counterboring, and more.

Drilling is one of the most common operations performed on a milling machine. This involves using a drill bit to create a hole in the material being worked on. The drill bit is held in a chuck and rotated at a high speed to create the hole. The size of the hole is determined by the size of the drill bit being used.

Reaming is another common operation performed on a milling machine. This involves using a reamer to enlarge an existing hole. The reamer is held in a chuck and rotated at a high speed to enlarge the hole. The size of the hole is determined by the size of the reamer being used.

What are the two milling machines?

Milling machines are a type of machine tool used for shaping and machining metal and other materials. They are typically used to produce precision parts and components for a variety of industries, including automotive, aerospace, medical, and electronics. There are two main types of milling machines: vertical milling machines and horizontal milling machines.

Vertical milling machines are designed to cut material from the top down, using a rotating spindle and a vertical table to hold the material in place. The spindle is driven by a motor, which moves the cutting tool up and down. The cutting tool is usually a drill bit, end mill, or router bit. Vertical milling machines are used for a variety of applications, including drilling, boring, and contouring.

Horizontal milling machines are designed to cut material from the side, using a rotating spindle and a horizontal table to hold the material in place. The spindle is driven by a motor, which moves the cutting tool left and right. The cutting tool is usually a drill bit, end mill, or router bit.

What are the types of milling machine?

Milling machines are tools used in the metalworking industry for shaping solid materials like metal, wood, plastic, and foam. They are typically powered by electric motors and are used to shape materials by cutting, drilling, grinding, and other machining processes. There are several different types of milling machines, each with its own unique characteristics and capabilities.

The most common type of milling machine is the vertical milling machine. This type of machine has a spindle that is oriented vertically, and the workpiece is clamped to the bed of the machine. The spindle can move up and down, and the workpiece can be moved in the X, Y, and Z directions. This type of machine is used for a variety of machining operations, including drilling, reaming, boring, and milling.

Another type of milling machine is the horizontal milling machine. This type of machine has a spindle that is oriented horizontally, and the workpiece is clamped to the bed of the machine.

What is face milling operation?

Face milling is a machining process used to remove material from the surface of a workpiece. It is a type of milling operation that uses a rotating cutter to remove material from the surface of a workpiece in a direction perpendicular to the axis of the cutter. The cutter is usually mounted on a spindle and is held in place by a tool holder. The cutting action is performed by the teeth of the cutter as it rotates and moves along the surface of the workpiece.

Face milling is used to produce flat surfaces, slots, grooves, and contours. It is also used to produce shallow pockets and to machine angled surfaces. The cutting action of the face milling process is similar to that of end milling, but the cutter is mounted on a spindle and is held in place by a tool holder. The cutting action is performed by the teeth of the cutter as it rotates and moves along the surface of the workpiece.

The face milling process is used to produce a wide variety of parts, including automotive components, aerospace components, and medical components.

What is the difference between plain and side milling operation?

Milling is a machining process that uses a rotating cutting tool to remove material from a workpiece. Plain milling is a type of milling operation in which the cutting tool moves parallel to the workpiece surface. Side milling is a type of milling operation in which the cutting tool moves perpendicular to the workpiece surface.

Plain milling is used to produce flat surfaces that are parallel to the axis of the workpiece. It is also used to produce grooves, slots, and keyways. The cutting tool used for plain milling is usually a plain milling cutter, which is a multi-toothed cutter that has straight or helical teeth.

Side milling is used to produce flat surfaces that are perpendicular to the axis of the workpiece. It is also used to produce grooves, slots, and keyways. The cutting tool used for side milling is usually a side milling cutter, which is a multi-toothed cutter that has straight or helical teeth.

What the two common types of milling machine and how are they distinguished from each other?

Milling machines are used to shape and cut materials in a variety of industrial and commercial applications. There are two common types of milling machines: vertical milling machines and horizontal milling machines.

Vertical milling machines have a vertical spindle that is perpendicular to the work surface. The spindle holds the cutting tool and is driven by an electric motor. The cutting tool is moved up and down in a linear motion, and the workpiece is moved across the spindle to create the desired shape. Vertical milling machines are generally used for smaller parts and can be used to create complex shapes.

Horizontal milling machines have a horizontal spindle that is parallel to the work surface. The spindle holds the cutting tool and is driven by an electric motor. The cutting tool is moved in a rotary motion, and the workpiece is moved across the spindle to create the desired shape. Horizontal milling machines are generally used for larger parts and can be used to create more intricate shapes.

What is column and knee type milling?

Column and knee type milling is a form of milling machine that uses a vertical spindle and a horizontal table to cut and shape materials. The spindle is mounted on a vertical column, which is connected to the base of the machine. The table is mounted on a knee, which is connected to the column and can be adjusted up and down. The spindle is driven by a motor, which is connected to the column and can be adjusted to different speeds.

The column and knee type milling machine is one of the most versatile and widely used milling machines. It is capable of performing a variety of operations, including cutting, drilling, boring, and reaming. It is also capable of performing complex operations such as contouring, profiling, and helical milling. The column and knee type milling machine is used in a variety of industries, including automotive, aerospace, and medical.