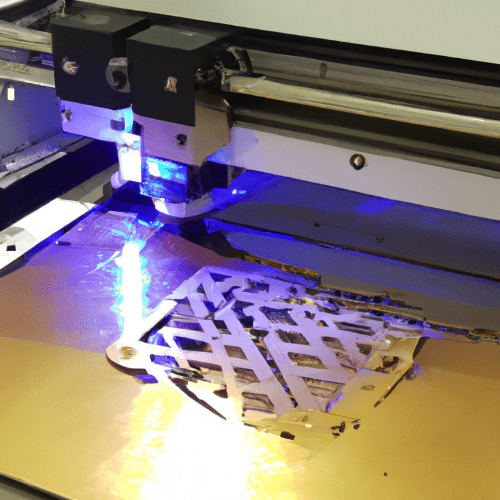

A laser cutter is a powerful tool that can be used to cut, engrave, and mark a variety of materials. It is a type of CNC (Computer Numerical Control) machine that uses a laser beam to cut and engrave materials. Laser cutters are used in a variety of industries, including manufacturing, engineering, and design.

The most common use of a laser cutter is to cut materials such as wood, acrylic, paper, cardboard, and fabric. The laser beam is focused on the material and the material is cut along the desired line. Laser cutters can also be used to engrave materials such as wood, metal, and glass. The laser beam is focused on the material and the material is engraved along the desired line.

Laser cutters can also be used to mark materials such as metal and plastic. The laser beam is focused on the material and the material is marked with a permanent mark. This is often used in the manufacturing industry to mark parts with serial numbers or other identifying information.

In addition to cutting and engraving, laser cutters can also be used to create 3D objects. This is done by using a 3D printer to create a 3D model of the object, and then the laser cutter is used to cut the 3D model into the desired shape.

Finally, laser cutters can also be used to create intricate designs and patterns. This is done by using a vector file to create a design, and then the laser cutter is used to cut the design into the desired material. This is often used in the design industry to create custom designs for products or artwork.

What can a laser cutter be used for?

A laser cutter is a type of machine that uses a laser beam to cut or engrave materials such as wood, plastic, metal, and even fabric. It is a versatile tool that can be used for a variety of applications, including cutting, engraving, marking, and etching. Laser cutters are used in a variety of industries, including manufacturing, engineering, and design.

In manufacturing, laser cutters are used to cut and shape materials for a variety of products, such as automotive parts, medical devices, and consumer electronics. They can also be used to create intricate patterns and designs on a variety of materials. Laser cutters are also used in engineering to create prototypes and models for testing and development.

In design, laser cutters are used to create intricate patterns and designs on a variety of materials, such as wood, plastic, metal, and fabric. They can also be used to create custom logos and signage. Laser cutters are also used in the arts and crafts industry to create unique and intricate designs on a variety of materials.

Can you make money with a laser cutter?

Yes, you can make money with a laser cutter. Laser cutters are a versatile tool that can be used to create a variety of products, from custom signs and labels to intricate jewelry and artwork. With the right materials and a bit of creativity, you can turn your laser cutter into a profitable business.

The first step to making money with a laser cutter is to determine what type of products you want to create. You can use a laser cutter to create custom signs, labels, and artwork, as well as intricate jewelry and other items. Once you have decided what type of products you want to create, you can start researching the materials and supplies you will need to get started. You will also need to decide on a pricing structure for your products.

Once you have the materials and supplies you need, you can start creating your products. You can use a variety of software programs to design your products, or you can create them from scratch. Once you have designed your products, you can use your laser cutter to cut them out of the materials you have chosen.

Can a laser cutter cut a mirror?

Yes, a laser cutter can cut a mirror. Laser cutters use a focused beam of light to cut through materials, and mirrors are no exception. The laser beam is focused on the surface of the mirror, and the heat generated by the beam causes the material to melt, vaporize, or burn away. Depending on the type of laser cutter being used, the beam can be adjusted to cut through different thicknesses of material. The laser cutter can also be used to engrave or etch designs into the surface of the mirror.

When cutting a mirror with a laser cutter, it is important to take safety precautions. The laser beam is very powerful and can cause serious injury if not handled properly. It is also important to use the correct settings on the laser cutter to ensure that the mirror is cut properly. Additionally, the laser cutter should be set up in a well-ventilated area to prevent the fumes from the burning material from becoming hazardous.

Can a laser cutter cut wood?

Yes, a laser cutter can cut wood. Laser cutters use a highly focused beam of light to cut through materials, and wood is one of the materials that can be cut with a laser cutter. The laser cutter works by focusing a beam of light onto the material, which causes the material to heat up and vaporize. The laser cutter is able to cut through the material by vaporizing it, and the laser cutter can be adjusted to cut through different thicknesses of wood.

When cutting wood with a laser cutter, it is important to use the correct settings for the material being cut. The laser cutter should be set to the correct power and speed for the material being cut, and the focus of the beam should be adjusted to ensure that the cut is clean and precise. Additionally, the type of wood being cut should be taken into consideration, as some woods are more difficult to cut than others.

Can you cut metal with a laser cutter?

Yes, you can cut metal with a laser cutter. Laser cutters use a focused beam of light to cut through materials, and metal is one of the materials that can be cut with a laser cutter. The laser cutter works by focusing a beam of light onto the material, which is then absorbed by the material and causes it to heat up and melt. The laser cutter then follows a predetermined path to cut the material into the desired shape.

The type of metal that can be cut with a laser cutter depends on the type of laser cutter being used. Some laser cutters are designed to cut through softer metals such as aluminum, while others are designed to cut through harder metals such as steel. The thickness of the metal also affects the type of laser cutter that is needed. Thicker metals require more powerful laser cutters, while thinner metals can be cut with less powerful laser cutters.