The cost of CNC turning depends on a variety of factors, including the complexity of the part, the material used, the number of parts to be produced, and the turnaround time. Generally, CNC turning is more expensive than manual turning due to the cost of the machinery and the programming required to produce the parts. The cost of CNC turning also depends on the type of CNC machine used, as some machines are more expensive than others. Additionally, the cost of CNC turning can vary depending on the type of tooling used, as some tooling is more expensive than others.

The cost of CNC turning also depends on the type of material used. For example, aluminum is generally less expensive than steel, and titanium is more expensive than both. Additionally, the cost of CNC turning can vary depending on the complexity of the part. Parts with more complex shapes and features will require more time and effort to produce, and thus will cost more.

Finally, the cost of CNC turning can also depend on the number of parts to be produced. Generally, the more parts that need to be produced, the lower the cost per part. Additionally, the turnaround time can also affect the cost of CNC turning, as parts that need to be produced quickly may require additional labor and materials, resulting in a higher cost.

How much does it cost to CNC?

The cost of CNC machining depends on a variety of factors, including the type of machine used, the complexity of the part being machined, the material used, and the number of parts being machined. Generally speaking, CNC machining can range from a few hundred dollars for a simple part to tens of thousands of dollars for a complex part. The cost of CNC machining also depends on the type of machine used. For example, a 3-axis CNC milling machine is typically less expensive than a 5-axis CNC milling machine. Additionally, the cost of CNC machining can vary depending on the material used. For example, machining aluminum is typically less expensive than machining stainless steel. Finally, the cost of CNC machining can also vary depending on the number of parts being machined. For example, machining one part is typically less expensive than machining multiple parts.

How is CNC turn machine hour rate calculated?

The CNC turn machine hour rate is a measure of the cost of running a CNC turning machine for one hour. It is calculated by taking the total cost of running the machine for a given period of time (usually one hour) and dividing it by the number of parts produced during that period. This cost includes the cost of the machine itself, the cost of the materials used, the cost of labor, and any other costs associated with running the machine.

The cost of the machine itself is usually the largest component of the CNC turn machine hour rate. This cost includes the purchase price of the machine, any installation costs, and any maintenance costs. The cost of the materials used is also a major factor in the calculation of the CNC turn machine hour rate. This includes the cost of the raw materials, any cutting tools, and any other materials used in the production process. The cost of labor is also a factor in the calculation of the CNC turn machine hour rate.

How is CNC machine pricing calculated?

CNC machine pricing is typically calculated based on a variety of factors, including the type of machine, the size of the machine, the features and capabilities of the machine, and the complexity of the parts that the machine will be used to produce. The cost of the machine will also depend on the manufacturer, the quality of the components, and the availability of parts and service. Additionally, the cost of the machine will be affected by the cost of the materials used to produce the parts, the cost of labor, and the cost of shipping and handling.

When calculating the cost of a CNC machine, it is important to consider the cost of the machine itself, as well as the cost of the software and other components that are necessary to operate the machine. The cost of the software and other components can vary greatly depending on the type of machine and the complexity of the parts that the machine will be used to produce. Additionally, the cost of the machine will be affected by the cost of the materials used to produce the parts, the cost of labor, and the cost of shipping and handling.

How accurate is CNC turning?

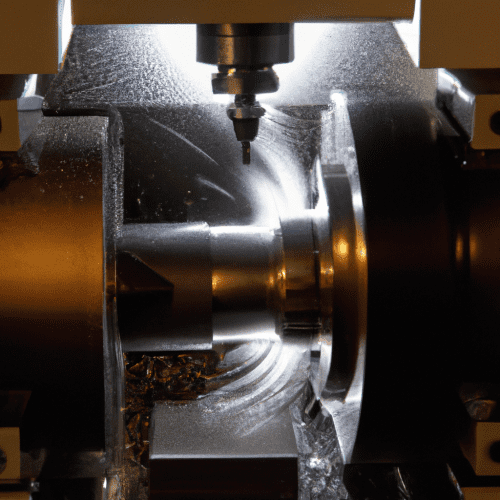

CNC (Computer Numerical Control) turning is a machining process that uses computer-controlled lathes to shape materials into a desired shape. CNC turning is a highly accurate process, with the ability to produce parts with tight tolerances and repeatable accuracy. The accuracy of CNC turning is determined by a variety of factors, including the quality of the machine, the type of tooling used, the programming of the machine, and the skill of the operator.

The accuracy of CNC turning is typically measured in terms of the tolerance of the finished part. Tolerance is the allowable deviation from the desired dimensions of the part. The tighter the tolerance, the more accurate the part will be. CNC turning can produce parts with tolerances as tight as 0.001 inches, depending on the machine and the material being machined.

The accuracy of CNC turning is also affected by the type of tooling used. The type of tooling used will determine the type of finish that can be achieved on the part.

Why is CNC machining so expensive?

CNC machining is a highly precise and automated process that requires specialized equipment and highly trained personnel to operate. This makes it more expensive than other machining processes, such as manual machining. CNC machining also requires a high level of precision and accuracy, which can be costly to achieve. Additionally, CNC machines require a significant amount of energy to operate, which can add to the cost of the process. Furthermore, CNC machines require a large amount of maintenance and upkeep, which can also add to the cost. Finally, CNC machining requires a large amount of raw materials, which can be expensive depending on the type of material being used. All of these factors contribute to the overall cost of CNC machining, making it more expensive than other machining processes.

How much do you charge for CNC router work?

Thank you for your inquiry about CNC router work. The cost of CNC router work depends on the complexity of the project, the materials used, and the time required to complete the job. Generally, CNC router work is priced by the hour, with an additional cost for materials. The cost of materials can vary depending on the type of material used and the quantity needed.

In order to provide you with an accurate estimate, I would need to know more about the project you have in mind. If you could provide me with a detailed description of the project, including the type of material you would like to use, the size of the project, and any other relevant information, I would be happy to provide you with a more accurate estimate.

Is CNC a good career?

CNC (Computer Numerical Control) is a rapidly growing field that offers a wide range of career opportunities. CNC is a type of machining process that uses computer-controlled machines to cut and shape materials into precise shapes and sizes. CNC machines are used in a variety of industries, including aerospace, automotive, medical, and manufacturing.

CNC is a great career choice for those who are interested in working with technology and machines. CNC operators are responsible for setting up and operating CNC machines, as well as programming and troubleshooting them. They must be able to read and interpret blueprints and technical drawings, as well as understand the principles of machining and tooling. CNC operators must also be able to use a variety of measuring instruments and tools, such as calipers, micrometers, and gauges.

CNC operators typically receive on-the-job training, and may also need to complete a formal apprenticeship program. Those who are interested in advancing their career may choose to pursue a certificate or degree in CNC technology.

How much does a 5 axis CNC cost?

The cost of a 5 axis CNC machine can vary greatly depending on the size, type, and features of the machine. Generally, a 5 axis CNC machine can range anywhere from $50,000 to $500,000 or more. Smaller, desktop 5 axis CNC machines can cost as little as $10,000, while larger, industrial-grade 5 axis CNC machines can cost upwards of $1 million. The cost of a 5 axis CNC machine also depends on the type of materials it is made from, the number of axes it has, and the features it includes. For example, a 5 axis CNC machine with a larger work envelope, higher accuracy, and more advanced features will cost more than a basic 5 axis CNC machine. Additionally, the cost of a 5 axis CNC machine can vary depending on the manufacturer and the country of origin.

When purchasing a 5 axis CNC machine, it is important to consider the cost of the machine, as well as the cost of maintenance and repair.

How deep can a CNC cut?

The depth of cut that a CNC machine can achieve is determined by a variety of factors, including the size and power of the machine, the type of material being cut, and the type of cutting tool being used. Generally speaking, CNC machines are capable of cutting to depths of up to several inches, depending on the material and the cutting tool. For example, a CNC router with a 1/4 end mill can typically cut to a depth of up to 1/2 in soft materials such as wood, while a CNC mill with a 1/2 end mill can cut to a depth of up to 1 in harder materials such as aluminum. Additionally, CNC machines can be equipped with special tools such as drill bits and countersinks that can cut to even greater depths. Ultimately, the depth of cut that a CNC machine can achieve is limited only by the size and power of the machine, the type of material being cut, and the type of cutting tool being used.