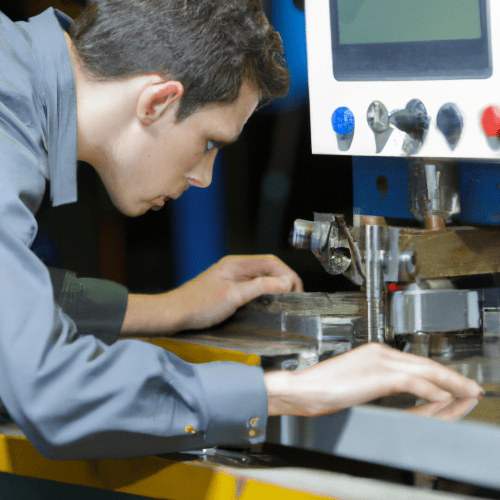

A CNC (Computer Numerical Control) machinist is a skilled professional who operates a CNC machine to create precision parts and components. CNC machines are computer-controlled tools that use a variety of cutting tools to shape and form materials into the desired shape. CNC machinists use a variety of software programs to create the necessary instructions for the CNC machine to follow. They must be able to read and interpret blueprints and technical drawings, as well as understand the principles of machining and the properties of the materials they are working with. CNC machinists must also be able to troubleshoot and adjust the machine as needed to ensure the accuracy of the finished product. CNC machinists must also be able to use a variety of measuring tools to ensure the accuracy of the finished product. CNC machinists must also be able to use a variety of safety equipment and procedures to ensure the safety of themselves and others in the work area.

Is CNC a good career?

CNC (Computer Numerical Control) is a great career choice for those who are interested in working with machines and technology. CNC is a type of machining process that uses computer-controlled machines to cut and shape materials into desired shapes and sizes. CNC machinists use computer-aided design (CAD) software to create 3D models of the parts they are creating, and then use CNC machines to cut and shape the materials into the desired shape. CNC machinists must be highly skilled in both the software and the machines they use, as well as have a good understanding of the materials they are working with.

CNC is a great career choice for those who are looking for a job that is both challenging and rewarding. CNC machinists are in high demand in many industries, including automotive, aerospace, medical, and manufacturing. CNC machinists can also find work in the entertainment industry, creating props and sets for movies and television shows.

What is the difference between a machinist and a CNC machinist?

The primary difference between a machinist and a CNC machinist is the type of equipment they use. A machinist typically uses manual tools such as lathes, milling machines, and grinders to shape and form metal and other materials. A CNC machinist, on the other hand, uses computer numerical control (CNC) machines to shape and form materials. CNC machines are programmed to perform specific tasks, such as cutting, drilling, and milling, with a high degree of accuracy and precision. CNC machinists must be familiar with computer programming and be able to troubleshoot any issues that may arise with the CNC machines. They must also be able to read and interpret blueprints and other technical drawings.

In addition to the difference in the type of equipment used, machinists and CNC machinists also have different job duties. Machinists are responsible for setting up and operating manual machines, as well as performing maintenance and repairs on them.

Is CNC machining hard?

CNC machining is not necessarily hard, but it does require a certain level of skill and knowledge to be successful. It is a complex process that involves programming a computer to control the movement of a machine tool, such as a lathe or milling machine. The programming language used to control the machine is called G-code, and it is a language that must be learned in order to be successful. Additionally, the operator must understand the principles of machining, such as cutting speeds, feeds, and depths of cut, as well as the types of materials that can be machined.

In addition to the programming and machining knowledge, the operator must also be familiar with the machine itself. This includes understanding the safety features, the proper setup of the machine, and the maintenance that is required to keep it running properly.

Overall, CNC machining is not necessarily hard, but it does require a certain level of skill and knowledge to be successful. With the right training and experience, anyone can become a successful CNC machinist.

What do you do in CNC?

CNC stands for Computer Numerical Control, and it is a process used in manufacturing that involves the use of computers to control machine tools. CNC machines are programmed with a set of instructions that tell the machine what to do and how to do it. The instructions are typically written in a computer language called G-code. The instructions tell the machine how to move, how fast to move, and what tools to use.

CNC machines are used to create a variety of products, from small parts to large components. They are used in a variety of industries, including automotive, aerospace, medical, and consumer products. CNC machines are used to create parts for cars, airplanes, medical devices, and consumer products.

CNC machines are programmed by a CNC programmer. The programmer creates the instructions for the machine, which are then loaded into the machine. The programmer also monitors the machine during operation to ensure that it is running correctly and producing the desired results.

How long does it take to get CNC certified?

The amount of time it takes to become CNC certified depends on the type of certification you are seeking. Generally, CNC certification programs can range from a few weeks to several months, depending on the complexity of the program and the level of certification you are seeking.

For entry-level CNC certification, you may be able to complete the program in as little as a few weeks. These programs typically cover the basics of CNC operation, such as safety, machine setup, and basic programming.

For more advanced CNC certification, such as a Master CNC certification, you may need to complete a more comprehensive program that can take several months to complete. These programs typically cover more advanced topics such as advanced programming, troubleshooting, and machine maintenance.

In addition to the length of the program, the amount of time it takes to become CNC certified also depends on the individual. Some people may be able to complete the program in a shorter amount of time, while others may need more time to fully understand the material.

Is CNC machining stressful?

CNC machining can be a stressful job, depending on the individual and the specific job. It requires a great deal of precision and accuracy, and mistakes can be costly. The job also requires a great deal of concentration and focus, and the operator must be able to work quickly and efficiently. Additionally, the operator must be able to troubleshoot any problems that arise, and must be able to make quick decisions in order to keep the machine running smoothly. The operator must also be able to work with a variety of materials, and must be able to adjust the machine settings accordingly.

Overall, CNC machining can be a very demanding job, and it requires a great deal of skill and knowledge. It can be stressful, especially when deadlines are tight and mistakes can be costly. However, with the right training and experience, it can be a rewarding and satisfying job.

How much can a CNC machine make?

A CNC (Computer Numerical Control) machine is a type of automated machine tool that uses computer programs to control the movement of the machine’s tools. CNC machines are used to produce a wide variety of products, from small components to large parts. The amount of money a CNC machine can make depends on a variety of factors, including the type of machine, the complexity of the parts being produced, and the number of parts being produced.

The type of CNC machine used will have a major impact on the amount of money it can make. For example, a CNC milling machine is typically used to produce parts with complex shapes, while a CNC lathe is used to produce parts with cylindrical shapes. The complexity of the parts being produced will also affect the amount of money a CNC machine can make. Parts with more complex shapes and features will require more time and effort to produce, and thus will cost more money. Finally, the number of parts being produced will also affect the amount of money a CNC machine can make.

Is CNC machining profitable?

CNC machining can be a very profitable business, depending on the type of machining being done and the size of the business. CNC machining involves the use of computer numerical control (CNC) machines to create parts and components from a variety of materials. CNC machines are highly precise and can produce parts with a high degree of accuracy and repeatability. This makes them ideal for producing parts for a variety of industries, including aerospace, automotive, medical, and consumer products.

The profitability of CNC machining depends on a variety of factors, including the type of machining being done, the size of the business, the cost of materials, and the cost of labor. For example, a small business that specializes in producing small parts for consumer products may be able to make a profit with a relatively small investment in CNC machines and materials. On the other hand, a larger business that specializes in producing complex parts for the aerospace industry may require a much larger investment in CNC machines and materials in order to be profitable.

What do CNC operators make?

CNC (Computer Numerical Control) operators are responsible for operating and programming CNC machines, which are used to cut and shape materials such as metal, plastic, and wood. CNC operators typically work in manufacturing plants, machine shops, and other industrial settings.

The salary of a CNC operator depends on a variety of factors, including the type of CNC machine they are operating, the complexity of the job, the size of the company, and the location of the job. Generally, CNC operators make between $14 and $25 per hour, with experienced operators making more. Some CNC operators may also receive benefits such as health insurance, paid vacation, and retirement plans.

In addition to operating and programming CNC machines, CNC operators are also responsible for performing routine maintenance and troubleshooting on the machines. They must also be able to read and interpret blueprints and other technical documents, as well as use precision measuring tools. CNC operators must also be able to work with a variety of materials, including metals, plastics, and wood.

Is CNC machinist in demand in Canada?

Yes, CNC machinists are in high demand in Canada. According to the Government of Canada’s Job Bank, CNC machinists are among the top 10 most in-demand occupations in the country. This is due to the fact that CNC machinists are highly skilled workers who are able to operate computer numerical control (CNC) machines, which are used to create precision parts and components for a variety of industries. CNC machinists are also in demand because they are able to work with a variety of materials, including metals, plastics, and composites.

The demand for CNC machinists is expected to remain strong in the coming years, as the manufacturing industry continues to grow and evolve. This is due to the fact that CNC machines are becoming increasingly sophisticated and are being used to create more complex parts and components. As a result, CNC machinists are needed to operate these machines and ensure that the parts and components they produce meet the highest standards of quality.