CNC lathes and turning centers are two types of machines that are commonly used in the manufacturing industry. While they may appear similar at first glance, there are distinct differences between these two machines. Understanding the dissimilarity between CNC lathes and turning centers is essential for selecting the right machine for your specific machining needs.

When comparing CNC lathes and turning centers, it’s important to consider their features, capabilities, and applications. CNC lathes are manual or semi-automated machines that are easy to set up and operate, making them suitable for toolrooms, designers, and lower production requirements. Turning centers, on the other hand, offer additional features such as automated tool changing, live rotating tools, efficient chip removal, and the ability to complete multiple components in one setup.

Let’s delve deeper into the key differences between CNC lathes and turning centers.

- CNC lathes and turning centers have distinct differences in terms of features and capabilities.

- CNC lathes are manual or semi-automated machines suitable for toolrooms and lower production requirements.

- Turning centers offer advanced features such as automated tool changing and live rotating tools.

- CNC lathes are easy to set up and operate, while turning centers are more efficient for high-volume production.

- The choice between the two depends on specific project requirements and production needs.

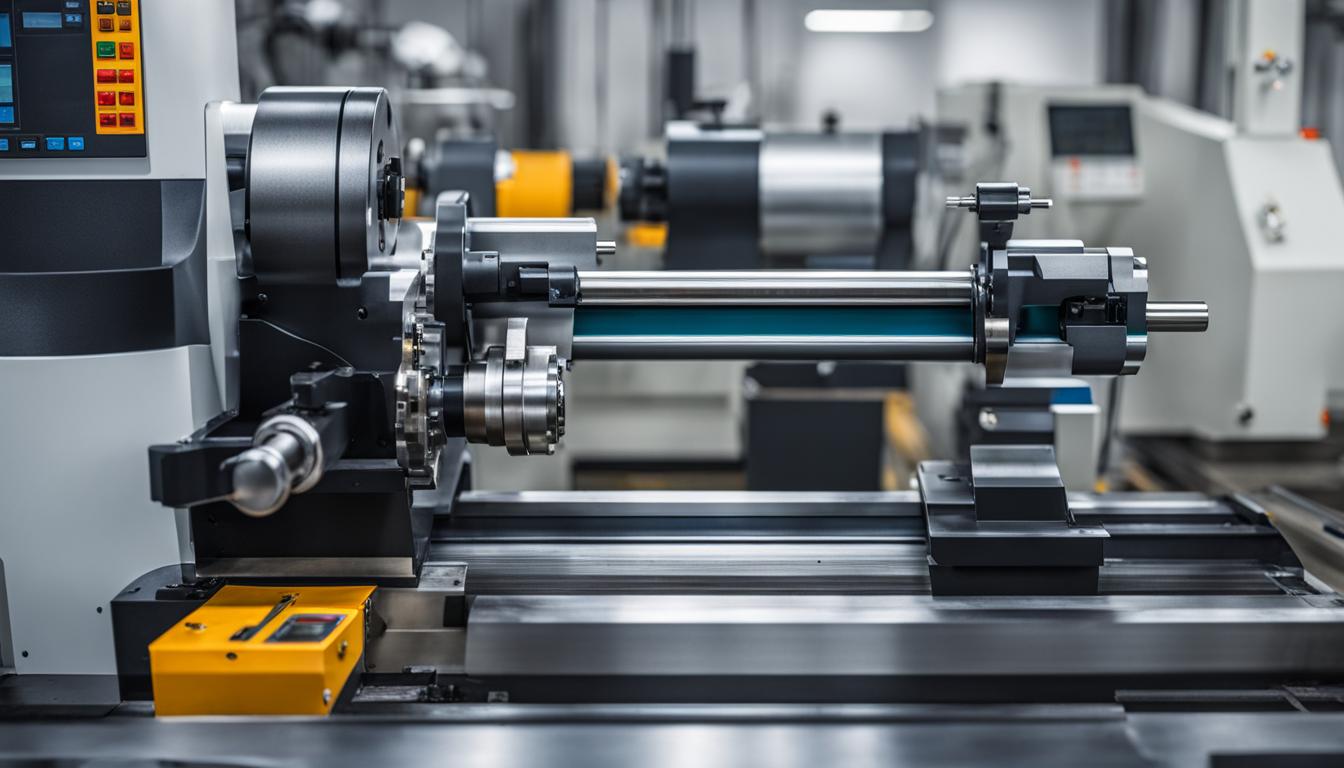

What is a CNC Lathe Machine?

A CNC lathe machine is an upgrade of a traditional lathe that incorporates computer numerical control (CNC) technology. With CNC lathes, repetitive production becomes more efficient and precise due to the automated control system. The CNC system enables the operation of the machine through pre-programmed instructions, eliminating the need for manual intervention in the machining process.

One of the key advantages of a CNC lathe machine is its ability to achieve multi-axis control. This means that the machine can move the cutting tool and workpiece simultaneously in various directions, allowing for complex and precise machining operations.

Furthermore, CNC lathes feature a flat bed design. The flat bed provides a stable platform for the workpiece and allows for a smooth and accurate machining process. The design also facilitates easy access to the workpiece, making setup and adjustment convenient.

One notable feature of CNC lathes is their manual controllability. Operators can easily program and operate these machines, making them suitable for toolrooms, designers, and lower production requirements. The manual control interface allows operators to input commands, set parameters, and monitor the machining process.

| Features | Benefits |

|---|---|

| Repetitive production | Efficient and consistent machining of multiple identical parts |

| Multi-axis control | Allows for complex and precise machining operations |

| Flat bed design | Provides stability and ease of access for setup and adjustment |

| Manual controllability | Easy programming and operation for toolrooms and lower production requirements |

What is a Turning Center Machine?

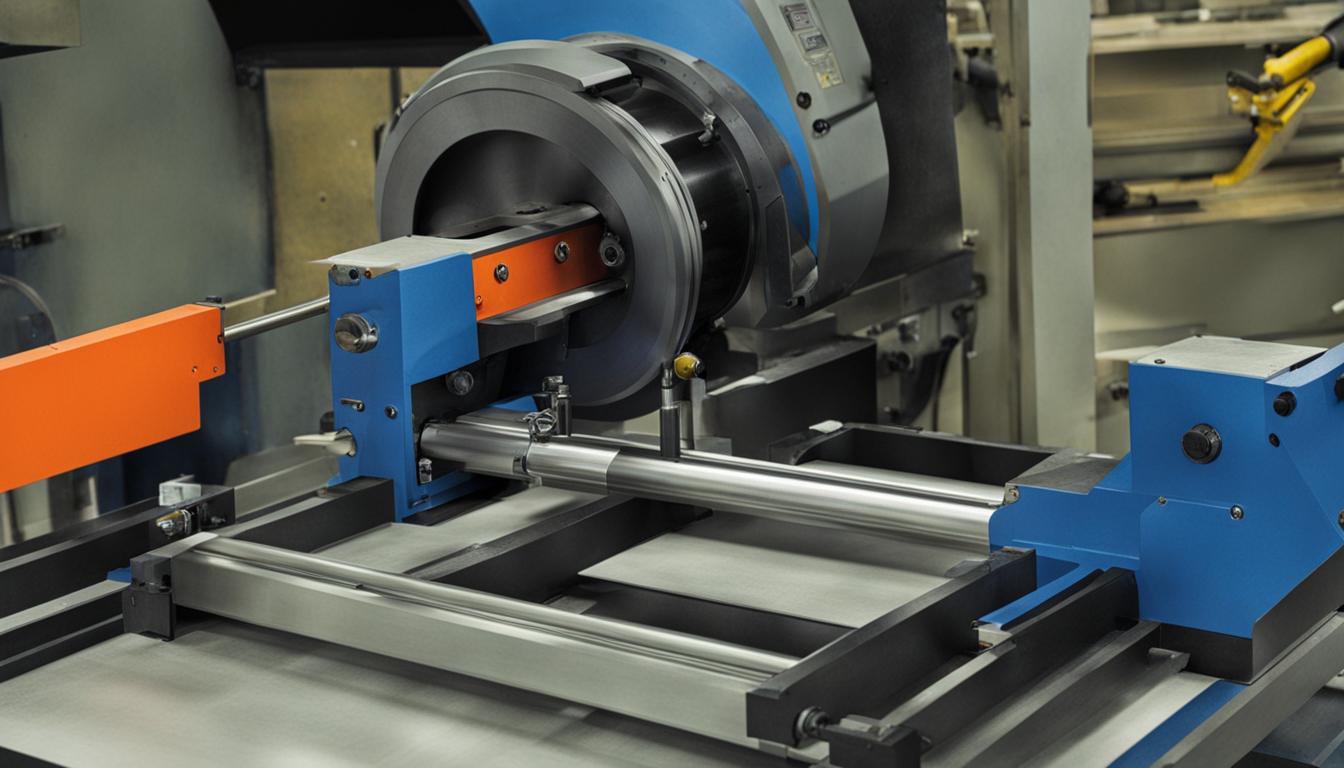

A turning center machine is an advanced version of a lathe with additional features and capabilities. It incorporates cutting-edge technology to enhance precision and efficiency in machining operations. One of the key distinguishing features of a turning center machine is its full machine enclosure, which provides a safe working environment by protecting operators and the surrounding area from chips and coolant.

The turning center machine also boasts a slant bed design, allowing for efficient chip removal during the machining process. This design feature ensures smooth and uninterrupted operations, reducing downtime and increasing productivity. Additionally, the turning center machine has a higher RPM capability, enabling faster cutting speeds and improved machining accuracy.

Live tools are another impressive feature found in turning center machines. These tools can be easily integrated into the turret, allowing for milling, drilling, and tapping operations to be performed on the workpiece without the need for additional setups. This versatility eliminates the need to transfer the workpiece to other machines, saving time and improving overall efficiency.

Automated tool changing is a critical capability of turning center machines. It eliminates manual tool changes, reducing setup time and minimizing errors. With automated tool changing, the machine can quickly switch between different cutting tools without any interruption, enabling seamless and uninterrupted machining processes.

Types of Turning Centers

Turning center machines come in two main types: horizontal turning centers and vertical turning centers. Horizontal turning centers feature a horizontal spindle orientation, making them ideal for a wide range of applications. These machines are commonly used for turning, facing, and threading operations.

Vertical turning centers, on the other hand, have a vertical spindle orientation. This design allows for efficient machining of large and heavy workpieces. Vertical turning centers are often used for turning operations that require heavy-duty cutting and deep hole drilling.

To summarize, a turning center machine is a highly advanced and versatile machining tool that offers significant advantages over traditional lathes. With its full machine enclosure, slant bed design, higher RPM capability, live tools, and automated tool changing, a turning center machine provides superior performance, precision, and efficiency in a wide range of applications.

CNC Turning Centers vs CNC Lathes: Differences in Processing Object

One key difference between CNC turning centers and CNC lathes lies in the processing object. Lathes are primarily used for machining cylindrical parts that can rotate 360 degrees. Turning centers, on the other hand, are designed for box-like parts that require more complex machining operations.

Let’s take a closer look at the processing objects for each machine:

CNC Lathes

CNC lathes excel in machining cylindrical parts. These parts can be solid or hollow and can have various diameters and lengths. Lathes are capable of turning and facing operations, allowing for the creation of perfectly round and symmetric components. The cylindrical parts are mounted on a rotating spindle and can be machined from all angles, giving flexibility in design and production.

CNC Turning Centers

Turning centers are specifically designed to handle the machining of box-like parts. The complex shapes and features of box-like parts require precise cutting, milling, and drilling operations. The robust construction and advanced capabilities of turning centers allow for efficient material removal, accurate positioning, and versatile tooling options.

The choice between CNC turning centers and CNC lathes depends on the specific project requirements. If you need to machine cylindrical parts with rotational symmetry, a CNC lathe would be the appropriate choice. On the other hand, if your project involves the machining of box-like parts with complex features and multi-axis operations, a CNC turning center would be better suited to meet your needs.

Difference in Rotation Mechanism

Another significant difference between CNC turning centers and CNC lathes lies in their rotation mechanisms. This distinction plays a crucial role in the versatility and machining capabilities of these machines.

In traditional lathes, the workpiece rotates while the cutting tools remain stationary. This allows for various operations such as turning, facing, and cylindrical shaping. However, it limits the types of machining that can be achieved.

On the other hand, turning centers feature a rotation mechanism where the cutting tools rotate while the workpiece remains stationary. This unique design enables the use of rotating cutting tools, making it possible to perform a broader range of machining operations like milling, drilling, and threading.

By allowing the cutting tools to rotate, turning centers enhance their versatility and expand the applications they can handle. They can produce more complex geometries and execute precise operations that would be challenging with a fixed cutting tool. This capability is particularly advantageous for industries that require intricate part designs and demanding machining operations.

Advantages of the Rotation Mechanism

The rotation mechanism in turning centers offers several advantages:

- Increased versatility in machining operations

- Capability to perform advanced milling, drilling, and threading operations

- Enhanced precision and accuracy

- Ability to handle complex geometries

Overall, the rotation mechanism in turning centers opens up new possibilities for manufacturers by enabling them to execute a wider range of machining tasks with cutting-edge precision and efficiency.

| CNC Lathes | CNC Turning Centers |

|---|---|

| Workpiece rotates | Cutting tools rotate |

| Primarily used for turning and cylindrical shaping | Can perform turning, milling, drilling, and threading operations |

| Ideal for simple parts and quick repairs | Suitable for complex part geometries and high-volume production |

As shown in the table above, the rotation mechanism ultimately determines the scope of machining operations, level of precision, and the types of projects each machine excels at.

Additional Features of Turning Centers

Turning centers offer several additional features that set them apart from CNC lathes. These advanced features enhance the efficiency and versatility of turning centers, making them ideal for high-production applications.

Automated Tool Changing

One of the key additional features of turning centers is the ability to perform automated tool changing. With automated tool changing capabilities, turning centers can seamlessly switch between different cutting tools without manual intervention. This saves valuable time and increases productivity, especially in complex machining operations where multiple tools are required.

Live Tooling Options

Turning centers also offer live tooling options, which enable them to perform milling and drilling operations in addition to turning. Live tooling allows for the integration of rotating tools directly on the turret, expanding the capabilities of the machine. This eliminates the need for secondary operations and reduces overall production time.

Multi-Axis Capabilities

Another notable feature of turning centers is their multi-axis capabilities. These machines can perform complex multi-axis operations, allowing for the production of intricate and precise components. With simultaneous control over multiple axes, turning centers can achieve high levels of accuracy and produce complex geometries that would be challenging to achieve with traditional CNC lathes.

Overall, the additional features of turning centers, such as automated tool changing, live tooling options, and multi-axis capabilities, make them well-suited for demanding machining tasks and high-volume production requirements. These features contribute to improved efficiency, increased productivity, and enhanced versatility.

Applications of CNC Turning Centers and CNC Lathes

Both CNC turning centers and CNC lathes have a wide range of applications in various industries. These machines are commonly used for machining round metal parts, bars, tubes, and gears, providing manufacturers with the flexibility to work with different materials and shapes. Whether it’s turning, facing, milling, or threading, CNC turning centers and lathes can efficiently and accurately perform these operations, ensuring high-quality outputs for diverse projects.

In the automotive industry, CNC turning centers and lathes are utilized for manufacturing precision components such as engine parts, shafts, and suspension components. In aerospace, these machines are instrumental in producing complex parts for aircraft engines, landing gear, and airframe structures. The electrical industry utilizes CNC turning centers and lathes for the production of connectors, terminals, and other electrical components.

Medical device manufacturers rely on CNC turning centers and lathes to produce intricate parts such as surgical instruments, implants, and prosthetics. These machines offer the precision and accuracy required for medical applications. Additionally, CNC turning centers and lathes are also employed in industries such as defense, telecommunications, and general machining, further highlighting their versatility.

With their ability to handle various materials and perform a wide array of operations, CNC turning centers and lathes are indispensable tools for modern manufacturing. Whether it’s crafting round metal parts, working with bars and tubes, or machining intricate gears, these machines deliver consistent and precise results, meeting the demands of today’s industrial applications.

Choosing the Right Machine for Your Project

When it comes to selecting the right machine for your project, it’s important to carefully consider your specific requirements and goals. The choice between a CNC lathe and a CNC turning center will depend on a variety of factors such as anticipated production rates, cycle times, and the need for automated operations and versatility in machining capabilities.

If your project involves short production runs, simple parts, or quick repairs, a CNC lathe may be the better choice. CNC lathes are easy to set up and operate, making them ideal for toolrooms, designers, and lower production requirements.

On the other hand, if your project requires high-volume production and material removal, a CNC turning center is the way to go. Turning centers offer additional features such as automated tool changing, live tooling options for milling and drilling, and the ability to perform complex multi-axis operations. These advanced capabilities make turning centers more efficient and versatile for demanding applications.

To help you make an informed decision, consider the following:

- Project requirements: Evaluate the specific requirements of your project, such as the complexity, dimensions, and materials of the parts to be machined.

- Production volume: Determine the anticipated production rates to ensure that the chosen machine can meet your output demands.

- Automation needs: Assess whether your project requires automated tool changing and multi-axis capabilities to enhance productivity and efficiency.

- Budget considerations: Take into account your budget constraints and compare the costs of CNC lathes and turning centers to find the best fit within your financial parameters.

By carefully considering these factors and weighing the advantages of CNC lathes and turning centers against your project requirements, you can confidently choose the right machine to achieve optimal results.