CNC machining and laser cutting are two distinct manufacturing processes with key differences in their operation, applications, and outcomes. CNC machining uses computer-controlled cutting tools to remove material from a workpiece, offering high precision and the ability to create complex 3D shapes. It excels in working with a wide range of materials, including metals, plastics, and wood, and is ideal for producing parts with tight tolerances.

Laser cutting, on the other hand, employs a focused beam of light to cut or engrave materials, providing exceptional accuracy for 2D designs and intricate patterns. It’s particularly effective for thin materials like sheet metal, acrylic, and fabric, offering clean edges and minimal material waste. CNC machining is more versatile in terms of material thickness and complexity of 3D shapes, while laser cutting is faster for 2D designs and offers superior edge quality. The choice between these technologies depends on factors such as material type, design complexity, production volume, and required finish quality, with each method having its own strengths in specific manufacturing scenarios.

- CNC cutting and laser cutting are both computer-controlled methods used in manufacturing.

- CNC cutting offers versatility and can work with a wide range of materials.

- Laser cutting is known for high precision and the ability to create intricate designs.

- When it comes to speed and efficiency, laser cutting is generally faster than CNC cutting.

- The choice between CNC cutting and laser cutting depends on the specific requirements and materials involved.

Understanding CNC Cutting

CNC cutting, or Computer Numeric Controlled cutting, is a manufacturing process that utilizes a router bit to accurately cut various shapes out of materials like wood, plastic, or metal. This process involves the use of a computer program that guides the cutting tool along a programmed path, ensuring precision and consistency in the cutting process.

CNC cutting offers numerous benefits, making it a popular alternative to traditional cutting methods. One of the key advantages is its versatility – CNC machines can cut a wide range of materials, allowing manufacturers to work with different materials for their projects. Additionally, CNC cutting offers efficiency in terms of high repeatability, meaning that the same cutting patterns can be effortlessly reproduced, ensuring consistent results.

Moreover, CNC cutting provides cost advantages. The use of computer-controlled systems reduces human error and increases productivity, resulting in lower production costs. This makes CNC cutting a cost-effective solution for manufacturers.

Overall, CNC cutting is a highly efficient and flexible cutting process that enables precise and consistent results, making it a preferred method over traditional cutting techniques.

| Benefits | Explanation |

|---|---|

| Versatility | CNC cutting can be used on a wide range of materials, including wood, plastic, and metal. |

| Efficiency | CNC cutting ensures high repeatability and consistency in the cutting process. |

| Cost advantages | The use of CNC machines reduces production costs through increased productivity and lower human error. |

Exploring Laser Cutting

Laser cutting is a manufacturing process that utilizes a high-powered laser beam to cut or engrave various materials. By focusing the laser beam through a lens system onto the material’s surface, the laser generates enough heat to melt, burn, or vaporize it, resulting in precise and intricate cuts. Laser cutting is suitable for a wide range of materials, including paper, fabric, acrylic, and certain types of metals. This process offers several benefits, including:

- High Precision: Laser cutting enables the creation of precise cuts with sharp corners, allowing for intricate and detailed designs.

- Versatility: Laser cutting can be used on various materials, making it a versatile choice for different applications.

- Suitability for Delicate Materials: Laser cutting is well-suited for working with delicate materials, such as paper and fabric, as it minimizes the risk of damage or distortion.

Laser cutting provides an efficient and effective alternative to traditional cutting methods, delivering exceptional results for projects that require a high level of precision and intricacy.

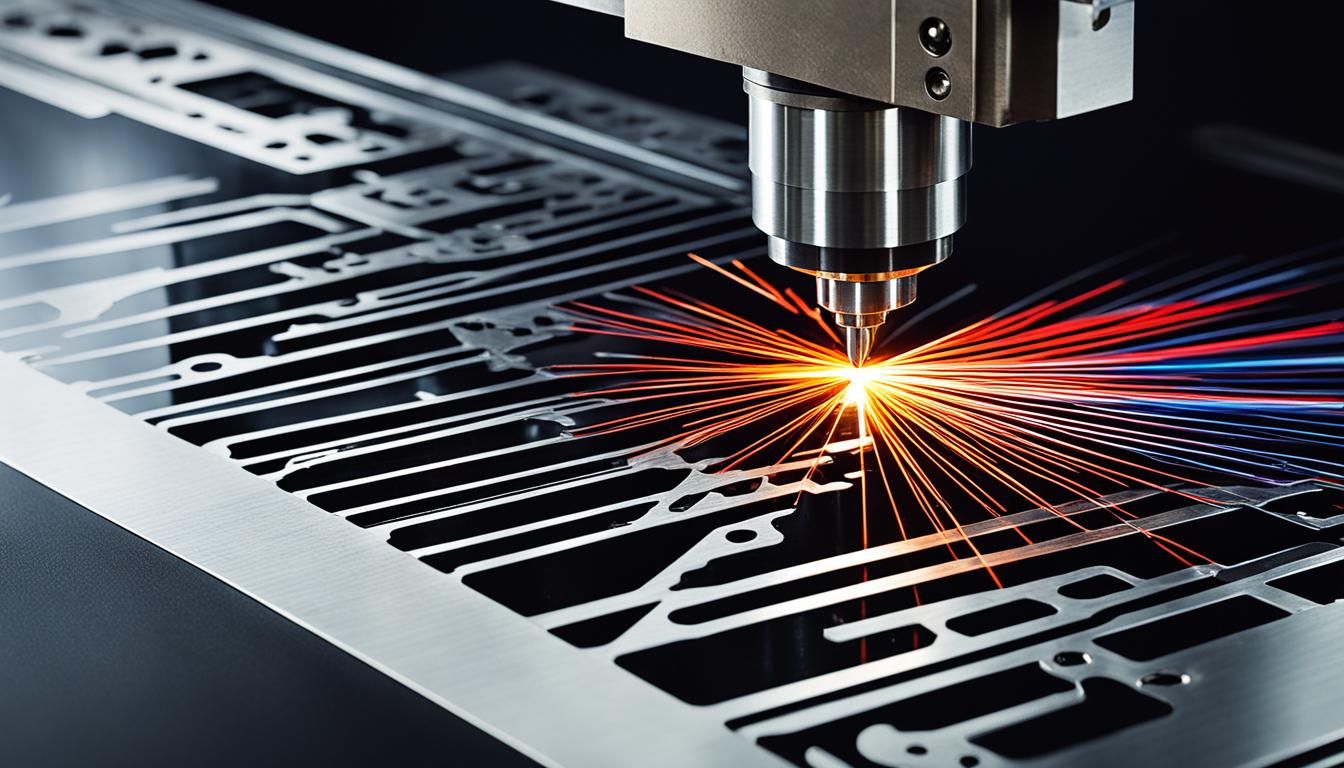

To visualize the process of laser cutting, take a look at the image below:

Laser Cutting vs. Traditional Cutting

| Aspect | Laser Cutting | Traditional Cutting |

|---|---|---|

| Precision | High | Varies based on the cutting method |

| Speed | Fast, especially for thin materials | Varies based on the cutting method |

| Versatility | Can work with a wide range of materials | Varies based on the cutting method |

| Applicability to Delicate Materials | High suitability | May cause damage or distortion |

The table above highlights the differences between laser cutting and traditional cutting methods across various aspects. Laser cutting stands out for its high precision, speed, versatility, and suitability for delicate materials, making it a preferred choice for many industries.

Speed and Efficiency Comparison

When it comes to cutting speed and efficiency, both CNC cutting and laser cutting have their own strengths and considerations. Let’s take a closer look at how these two methods compare:

CNC Cutting Speed

CNC cutting, with its computerized control and versatile milling capabilities, offers efficient cutting solutions for a wide range of materials. However, when compared to laser cutting, CNC cutting may be relatively slower, especially when working with thin materials.

Laser Cutting Speed

Laser cutting, on the other hand, can rapidly move and cut with high speed, making it an ideal choice for tasks that require quick and precise cutting. Its ability to swiftly maneuver the laser beam provides faster results, particularly for intricate designs and thin materials.

Ultimately, the choice between CNC cutting and laser cutting will depend on the specific requirements and materials involved. Consider the speed and efficiency needs of your project to determine which method best suits your needs.

Comparison Table: CNC Cutting vs. Laser Cutting Speed and Efficiency

| CNC Cutting | Laser Cutting | |

|---|---|---|

| Speed | Relatively slower, especially for thin materials | High speed, rapid cutting |

| Efficiency | Versatile and efficient for a wide range of materials | Faster results, particularly for intricate designs and thin materials |

Precision and Accuracy Comparison

When it comes to precision and accuracy, both CNC cutting and laser cutting offer their unique advantages. Let’s explore how these two methods compare in terms of achieving precise and accurate cuts:

CNC Cutting Precision

CNC cutting utilizes computer-controlled tools to cut materials with precision. The use of small cutting bits allows for intricate detailing and fine cuts. This precision makes CNC cutting suitable for a variety of applications that require accuracy, such as creating intricate designs or shaping delicate components.

However, it’s important to note that CNC cutting may have limitations when it comes to cutting thick materials. The depth and thickness of the material can affect the precision of the cuts. In such cases, alternative cutting methods may need to be considered.

Laser Cutting Precision

Laser cutting is renowned for its high precision and ability to achieve accurate cuts consistently. The focused laser beam can make very fine cuts with minimal material distortion, resulting in clean edges and sharp corners. This level of precision makes laser cutting ideal for tasks that demand intricate cuts and precise detailing.

Unlike CNC cutting, laser cutting is not hindered by material thickness. The laser beam can effectively cut through thin and thick materials with equal precision. This versatility allows for precise cuts across a wide range of materials, including metals, textiles, and plastics.

Overall, laser cutting offers superior precision and accuracy compared to CNC cutting, particularly when working with thin materials or intricate designs.

Here is a visual representation of the precision and accuracy capabilities of CNC cutting and laser cutting:

| CNC Cutting | Laser Cutting | |

|---|---|---|

| Precision | High precision, especially with small cutting bits | Superior precision, creates very fine cuts |

| Accuracy | Precise cuts, but limitations with thick materials | Accurate cuts with clean edges and sharp corners |

| Material suitability | Wide range of materials, may have limitations with thick materials | Versatile; suitable for various materials and thicknesses |

The table above highlights the differences in precision and accuracy between CNC cutting and laser cutting. It is clear that laser cutting excels in terms of achieving precise cuts with clean edges and sharp corners, regardless of material thickness.

Material Compatibility

When it comes to material compatibility, both CNC cutting and laser cutting offer versatility, but with some differences to consider. CNC cutting is capable of handling a wide range of materials, including wood, metal, and plastic. On the other hand, laser cutting, while also versatile, may have limitations when working with certain materials. Laser cutting is particularly well-suited for delicate materials such as paper, fabric, acrylic, and certain types of metals. The choice of cutting method depends on the specific materials and their requirements.

| CNC Cutting | Laser Cutting |

|---|---|

| Wide range of compatible materials, including wood, metal, and plastic | Particularly well-suited for delicate materials such as paper, fabric, acrylic, and certain types of metals |

| May face limitations when working with extremely thick materials | Offers precision and the ability to create intricate designs |

| Requires suitable cutting bits for specific materials | Can cause minimal material distortion resulting in precise cuts |

Cost Comparison

When deciding between CNC cutting and laser cutting, cost is an important factor to consider. In general, CNC cutting tends to be cheaper compared to laser cutting. CNC machines offer a cost-effective solution as they can cut a wide range of materials, making them ideal for various applications. On the other hand, laser cutting is often used for cutting super alloys and tough gemstones that require high precision cutting. This specialization can result in higher costs for laser cutting, particularly for industrial-grade machines.

When comparing the costs of CNC cutting and laser cutting, it’s important to take into account the specific requirements of your project and the materials involved. While CNC cutting may be more economical for general cutting needs, laser cutting can provide unmatched precision and accuracy for certain materials and designs.

Cost Comparison:

| Factors | CNC Cutting | Laser Cutting |

|---|---|---|

| Initial Investment | Lower initial cost of CNC machines compared to laser machines. | Higher initial cost of laser machines due to their advanced technology. |

| Operating Costs | Lower operating costs as CNC cutting can work with a wide range of materials. | Higher operating costs due to the specialized nature of laser cutting and the use of high-powered lasers. |

| Maintenance | Maintenance requirements can vary depending on the complexity of the CNC machine. | Laser machines generally require less maintenance due to their simplified design. |

| Material Costs | Materials suitable for CNC cutting are generally more cost-effective and widely available. | Specialized materials suitable for laser cutting may be more expensive. |

It’s important to carefully evaluate the costs and benefits of both CNC cutting and laser cutting to determine the most cost-effective option for your specific project. Consider factors such as material requirements, precision needs, and long-term costs when making your decision.

Repair and Maintenance Comparison

When it comes to repair and maintenance, there are significant differences between CNC cutting and laser cutting. CNC machines typically have numerous moving parts, which can make repairs and maintenance more complex and time-consuming. On the other hand, laser machines have fewer components and generally require less frequent repairs.

The simplicity of laser machines can result in lower repair and maintenance costs compared to CNC cutting. With fewer parts to monitor and maintain, laser cutting systems are typically easier to troubleshoot and fix, leading to reduced downtime and lower overall expenses.

It’s worth noting that routine maintenance is still essential for both CNC cutting and laser cutting systems. Regular inspections, cleaning, and calibration are necessary to ensure optimal performance and longevity. However, the frequency and complexity of maintenance tasks often vary between the two methods.

Comparison of Repair and Maintenance Considerations

| CNC Cutting | Laser Cutting | |

|---|---|---|

| Number of Moving Parts | Multiple moving parts | Fewer moving parts |

| Maintenance Complexity | Higher complexity | Lower complexity |

| Repair Costs | Can be higher | Typically lower |

| Maintenance Costs | May be higher | Generally lower |

Considering the long-term maintenance requirements and associated costs is crucial when selecting a cutting method. While CNC cutting systems offer versatility, they can be more demanding in terms of repairs and maintenance. On the other hand, laser cutting systems provide a simpler maintenance experience, resulting in potential cost savings over time.

Acceptance and Availability

Both CNC cutting and laser cutting have gained widespread acceptance in various industries. CNC cutting is highly regarded for its efficiency, high repeatability, and cost advantages. As a result, many machining shops offer CNC cutting services, making it easily accessible for different applications.

Laser cutting, on the other hand, is widely utilized in industries that demand precision and intricate designs. Its versatility and ability to create detailed cuts have made it a popular choice. However, the availability of laser cutting services may vary depending on location and industry requirements.

Let’s explore the acceptance and availability of both CNC cutting and laser cutting in a table:

| Factor | CNC Cutting | Laser Cutting |

|---|---|---|

| Acceptance | Widely accepted due to efficiency, repeatability, and cost advantages | High level of acceptance, especially in industries requiring precision and intricate designs |

| Availability | Readily available through many machining shops | Availability may vary based on location and industry requirements |

Choosing the Right Cutting Method

When it comes to deciding between CNC cutting and laser cutting, several factors need to be considered to make an informed choice. The specific requirements of the task, the materials involved, and the desired level of precision all play a crucial role in determining the appropriate cutting method.

CNC cutting, with its versatility, offers the ability to work with a wide range of materials such as metal, wood, and plastic. This makes it a reliable option for various projects. On the other hand, laser cutting excels in achieving high precision and is especially suitable for creating intricate designs. Known for its ability to cut delicate materials like fabric, paper, and certain metals, laser cutting is a popular choice for industries requiring exceptional precision.

Ultimately, the selection between CNC cutting and laser cutting depends on the specific needs and available resources of the project. Seeking advice from professionals in the field will help guide the decision-making process, ensuring that the chosen cutting method aligns with the desired outcome. By carefully considering the requirements and materials, the most suitable cutting method can be determined, leading to a successful and efficient manufacturing process.