Selecting the appropriate CNC coolant type is crucial for optimizing machining processes and ensuring the longevity of both tools and workpieces. The choice depends on several factors, including the material being machined, the type of operation, and environmental considerations. Water-soluble coolants are widely used for their excellent heat dissipation properties and are suitable for most general machining operations.

For more demanding applications, synthetic coolants offer enhanced lubrication and corrosion protection. Semi-synthetic coolants combine the benefits of both water-soluble and synthetic types, providing a balance between cooling and lubrication. When working with non-ferrous metals or in situations where staining is a concern, straight oils are often preferred. For high-speed machining or operations generating excessive heat, neat cutting oils can provide superior lubrication and tool life. It’s essential to consider the coolant’s compatibility with the machine components, its ability to resist bacterial growth, and its impact on operator health and safety.

Regular monitoring and maintenance of the coolant system, including proper concentration levels and pH balance, are vital for ensuring optimal performance and extending the coolant’s lifespan. By carefully evaluating these factors and consulting with coolant suppliers, manufacturers can select the most suitable CNC coolant type to maximize efficiency, improve surface finish quality, and reduce overall production costs.

- Choosing the right CNC coolant is vital for optimal machining performance and tool longevity.

- CNC coolant serves various purposes, including cooling the tools, lubricating the cutting process, and clearing away chips.

- There are different types of CNC coolants available, such as synthetic fluids, semi-synthetic fluids, straight oils, and soluble oils.

- Consider factors like the material being machined, the cutting process, and cooling requirements when selecting a coolant.

- Proper maintenance, including concentration monitoring and pH balance, is essential for maintaining the performance of the coolant.

What is CNC Coolant?

CNC coolant, also known as cutting fluid, is an industrial fluid used in metal cutting operations to enhance efficiency. It is composed of special chemical additives and various raw materials such as animal fat, water, petroleum distillate, and vegetable oil. CNC coolant improves the machining capabilities of CNC machines by reducing high-temperature build-up and facilitating chip removal. It plays a crucial role in cooling the workpiece at high speeds and lubricating the cutting tool at low speeds.

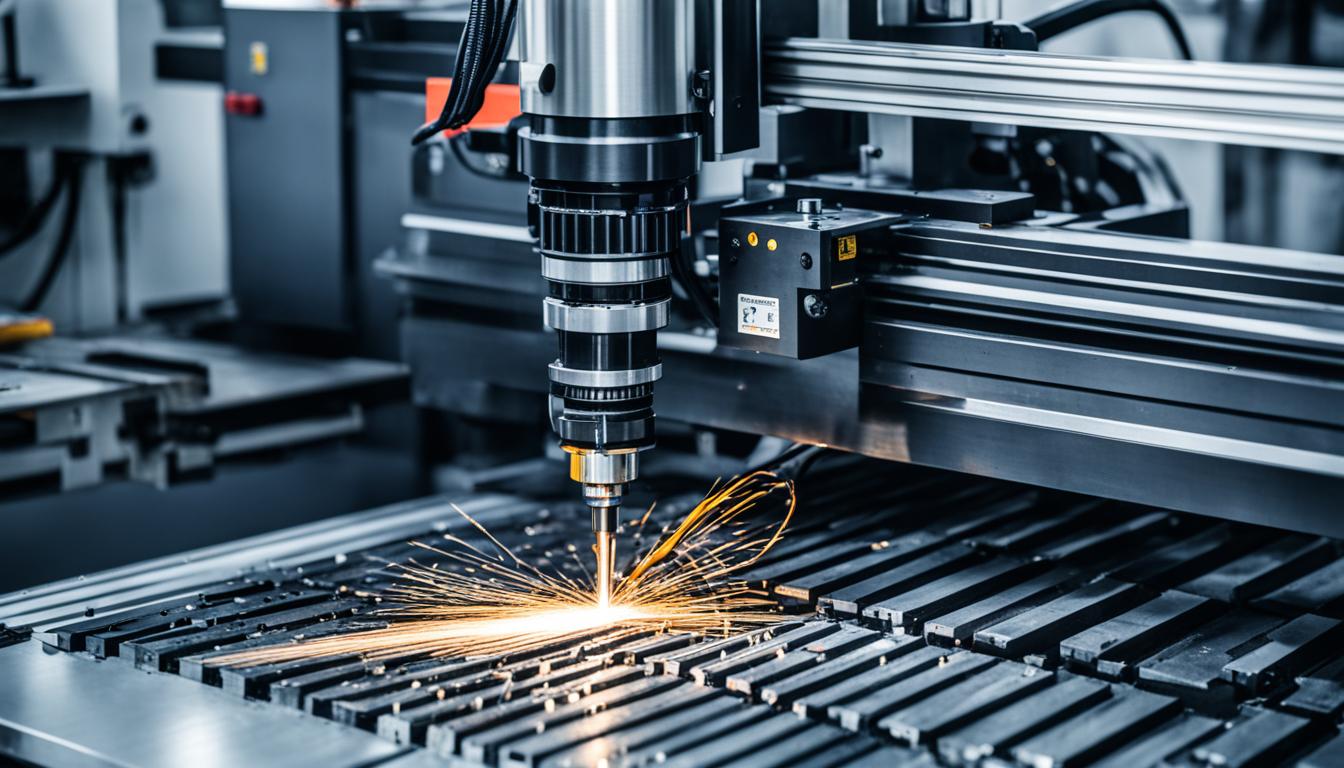

How Do Coolant Systems Work?

Coolant systems play a vital role in CNC machines by effectively managing the cooling and lubrication process during machining operations. Understanding how coolant systems work is essential for optimizing performance and ensuring the longevity of your CNC machine.

When engaged in CNC machining operations, a mixture of coolant is continuously flowed over the work area. This coolant serves multiple functions, including chip removal and cooling the workpiece. As the coolant flows over the work area, it effectively washes away chips and particles, preventing them from interfering with the machining process.

After clearing the work area, the coolant flows into a sump located at the bottom of the machine. From there, it is pumped and recirculated back to the work area, creating a continuous cycle. This constant flow of coolant helps maintain a stable operating temperature, preventing overheating and ensuring optimal machining performance.

In high-speed machining operations, coolant systems play a crucial role in cooling the workpiece. The coolant absorbs heat generated during the machining process, preventing thermal damage and maintaining dimensional accuracy. This cooling effect is especially important when working with heat-sensitive materials or conducting prolonged machining operations.

During low-speed machining operations, coolant systems provide lubrication to the cutting tools. By reducing friction and heat, the coolant minimizes tool wear and extends tool life. This lubricating function enhances the efficiency and precision of the machining process, enabling smoother chip removal and improved surface finishes.

To ensure the coolant system operates optimally, proper monitoring, maintenance, and adjustment are necessary. Regularly monitoring coolant levels, checking for any contamination or degradation, and adjusting the coolant concentration are essential steps to maintain the performance and effectiveness of the coolant system. Additionally, maintaining clean filters and ensuring proper coolant flow rate are crucial for efficient chip removal and cooling.

Benefits of Coolant Systems in CNC Machining Operations

- Efficient chip removal: Coolant systems effectively flush away chips and debris from the work area, preventing them from interfering with the machining process.

- Workpiece cooling: The continuous flow of coolant helps dissipate heat from the workpiece, preventing thermal damage and maintaining dimensional accuracy.

- Tool lubrication: Coolant systems provide lubrication to the cutting tools, reducing friction and heat generation, extending tool life, and improving machining efficiency.

- Improved surface finishes: Proper use of coolant systems can lead to smoother chip removal, reducing the risk of surface defects and achieving higher-quality surface finishes.

By understanding how coolant systems work and implementing proper maintenance practices, CNC machine operators can ensure optimal performance, improved tool life, and enhanced machining results.

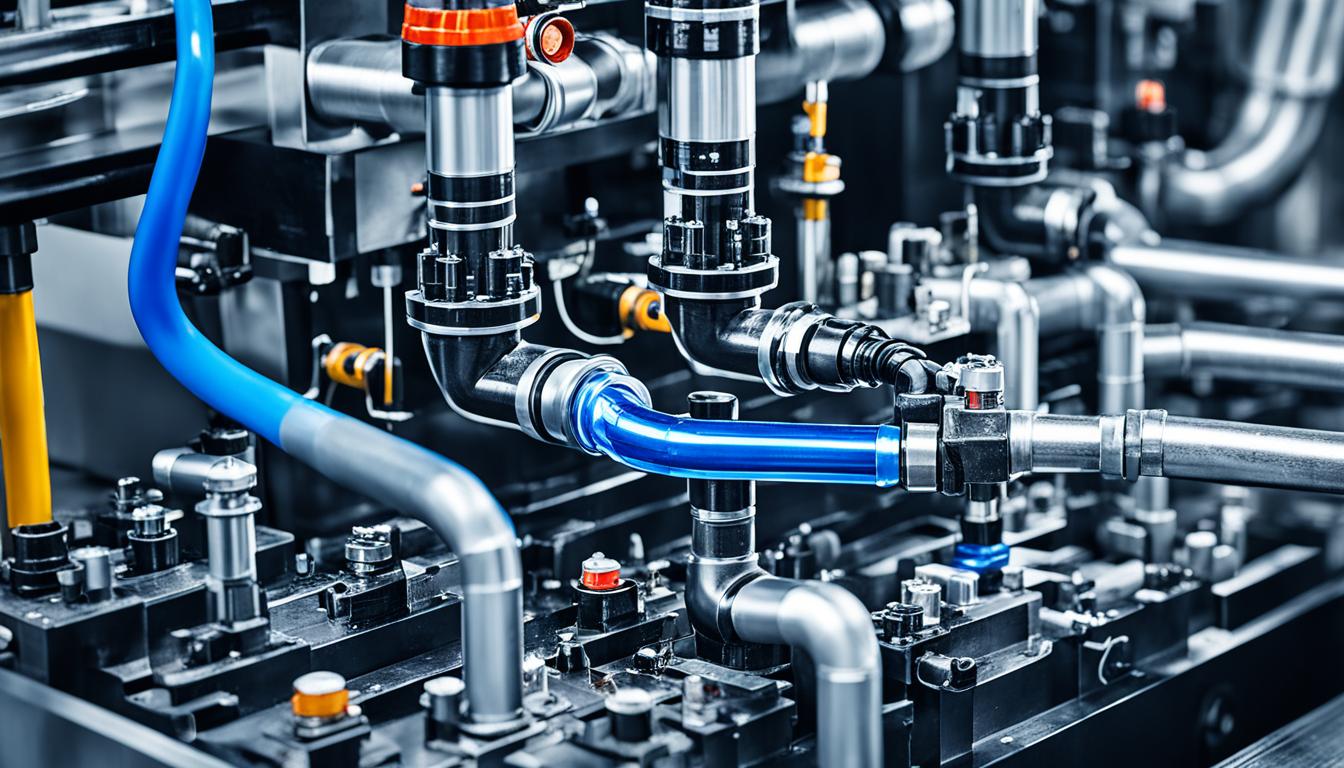

Various Coolant Delivery in CNC Machines

CNC machines utilize different types of coolant delivery mechanisms based on their specific needs. These mechanisms play a crucial role in maintaining the machining efficiency and prolonging the life of the cutting tools. Let’s explore some of the common coolant delivery methods used in CNC machines:

Mist Cooling Mechanism

The mist cooling mechanism is suitable for CNC machining operations where heat dissipation and chip removal are not the primary concerns. It involves spraying a fine mist of coolant over the cutting area, providing lubrication and minimal cooling.

Air Cooling Mechanism

The air cooling mechanism is ideal for CNC applications that involve direct contact with sensitive materials. It utilizes a controlled airflow to cool the workpiece and prevent heat-induced damage.

Minimum Quantity Lubrication (MQL) Mechanism

The minimum quantity lubrication (MQL) mechanism is designed to reduce coolant wastage by delivering the required amount of coolant in a fine mist or aerosol form. This method provides efficient lubrication and minimizes the environmental impact of coolant usage.

High-Pressure Mechanism

The high-pressure mechanism is used in CNC machines to remove chips during machining operations. It uses a coolant delivery system with pressure greater than 1,000 psi to effectively clear away chips and maintain a clean cutting area.

Each coolant delivery mechanism has its advantages and is chosen based on the specific requirements of the machining operation. By utilizing the appropriate coolant delivery mechanism, CNC machines can optimize their performance and enhance the overall machining process.

Types of CNC Machining Coolants

When it comes to CNC machining coolants, there are four main types to consider: synthetic fluids, semi-synthetic fluids, straight oils, and soluble oils. Each type offers unique benefits and characteristics that cater to different machining needs.

Synthetic fluids: These coolants are petroleum and mineral oil-free. They excel in providing exceptional cooling capacity, corrosion prevention, and ease of maintenance. Synthetic fluids are an excellent choice for high-performance machining operations.

Semi-synthetic fluids: As the name suggests, these coolants are a hybrid of synthetic fluids and soluble oils. They offer a balance of good lubricity and low viscosity, making them suitable for a wide range of machining applications. Semi-synthetic fluids are known for their versatility and compatibility with various materials.

Straight oils: Derived from different sources, straight oils provide good lubrication and rust prevention. However, they have limited cooling capabilities. Straight oils are commonly used in heavy-duty machining operations where cooling is not the primary concern.

Soluble oils: Soluble oils are water-based emulsions that offer excellent lubrication, heat transfer, and rust resistance. They are versatile and widely used in a range of machining applications. Soluble oils are particularly effective when working with ferrous metals and alloys.

It’s important to choose the right type of CNC machining coolant based on your specific machining requirements. Consider factors such as cooling capacity, lubrication, corrosion prevention, and compatibility with the material being machined. Consulting with coolant manufacturers or experts can provide valuable guidance in selecting the optimal coolant for your CNC machine.

Understanding CNC Machine Coolant Concentration

Maintaining the proper concentration of coolant in CNC machines is crucial for achieving optimal performance and prolonging the lifespan of the coolant. The concentration refers to the ratio of coolant to water and can vary depending on the specific machining operation. Proper coolant concentration is essential for ensuring the coolant’s cooling and lubricating properties are effectively utilized during the machining process.

Regularly monitoring and adjusting the coolant concentration are necessary steps to maintain its effectiveness. By regularly assessing the concentration levels, operators can ensure that the coolant is within the recommended range for the specific machining operation. This helps to prevent issues such as overheating or inadequate lubrication, which can compromise the machining process and negatively impact tool longevity.

Monitoring the coolant concentration can be done using a refractometer, a tool that measures the refractive index of a fluid and correlates it to the concentration level. By periodically checking the concentration using a refractometer, operators can make any necessary adjustments to maintain the desired coolant concentration.

It is important to note that different machining operations may require different coolant concentrations. Factors such as the material being machined, the cutting speed, and the desired level of heat dissipation all influence the appropriate coolant concentration. Therefore, it is recommended to consult the manufacturer’s guidelines or refer to industry standards to determine the optimal concentration range for specific machining applications.

By regularly monitoring and adjusting the coolant concentration, operators can ensure that their CNC machines are operating at peak performance. This helps to improve the overall machining efficiency, prolong the lifespan of the coolant, and enhance tool performance and longevity.

| Benefits of Maintaining Proper Coolant Concentration | Consequences of Improper Coolant Concentration |

|---|---|

| – Effective heat dissipation | – Overheating of tools and workpiece |

| – Optimal lubrication | – Inadequate lubrication |

| – Prevents corrosion | – Increased tool wear |

| – Improves chip evacuation | – Decreased machining efficiency |

| – Prolongs coolant lifespan | – Reduced tool lifespan |

Note: Maintaining the proper coolant concentration should always follow the manufacturer’s recommendations and industry best practices. It is also essential to regularly monitor the coolant’s pH balance and other maintenance requirements to ensure optimal coolant performance.

Water-Based Cutting Fluids vs. High-Pressure CNC Coolants

When it comes to machining performance and chip removal, the choice between water-based cutting fluids and high-pressure CNC coolants plays a crucial role. These two options are commonly used in the machining industry and offer distinct advantages for different applications.

Water-Based Cutting Fluids

Water-based cutting fluids are highly versatile and suitable for various machining operations. They offer excellent lubrication properties, enhancing the performance of cutting tools. These fluids also provide effective heat dissipation, preventing overheating during high-speed machining. Water-based cutting fluids are especially beneficial for machining non-ferrous alloys like aluminum due to their superior cooling capabilities.

One popular example of water-based cutting fluids is the OptiCool Ultra coolant, known for its exceptional performance in a wide range of machining applications. It is formulated with advanced additives that enhance cooling efficiency, chip removal, and extend tool life.

High-Pressure CNC Coolants

High-pressure CNC coolants work by utilizing pressure to remove chips during machining operations. These coolants are particularly effective for deep cavity machining, where chip removal can be challenging. By delivering the coolant at high pressures exceeding 1,000 psi, these systems can easily flush away chips and debris, ensuring uninterrupted machining performance.

The CNCProFlush HP coolant is a well-regarded high-pressure CNC coolant known for its outstanding chip removal capabilities. It is specially designed to handle deep cavity operations and optimize machining performance.

| Water-Based Cutting Fluids | High-Pressure CNC Coolants |

|---|---|

| Offers excellent lubrication properties | Utilizes high pressure to remove chips |

| Enhances machining performance | Optimizes chip removal |

| Superior cooling capabilities | Effective for deep cavity machining |

When selecting between water-based cutting fluids and high-pressure CNC coolants, it is important to consider the specific machining requirements. If efficient chip removal and deep cavity operations are critical, high-pressure CNC coolants are the ideal choice. On the other hand, for versatile machining applications and excellent lubrication and cooling properties, water-based cutting fluids are highly recommended.

Coolant Recommendations for CNC Machines

Choosing the right coolant for your CNC machine is essential for optimal performance and tool longevity. The selection process depends on various factors, including the material being machined, the type of cutting process, and the cooling requirements. Different coolant types offer unique benefits and are recommended for specific machining operations.

Synthetic Fluids: Synthetic fluids are highly recommended for high-heat, high-velocity machining processes. They are designed to withstand extreme temperatures, provide excellent cooling capacity, and offer superior lubrication. Synthetic fluids are ideal for heavy-duty applications and can enhance both tool life and machining efficiency.

Semi-Synthetic Fluids: Semi-synthetic fluids, also known as semi-chemical fluids, are a blend of synthetic fluids and soluble oils. They offer a balance between the benefits of both fluid types, providing moderate lubrication and cooling properties. Semi-synthetic fluids are suitable for moderate to heavy-duty applications and provide good tool life and corrosion protection.

When choosing a coolant, it is important to take into account the specific needs of your CNC machine and the machining operation. The manufacturer or their representative can provide valuable guidance and recommend the optimal coolant based on their expertise and knowledge.

In addition to coolant selection, regular maintenance and monitoring are necessary to ensure optimal coolant performance. This includes monitoring coolant concentration, pH balance, and implementing proper fluid management practices. By following recommended coolant guidelines and maintenance procedures, you can maximize the performance and lifespan of your CNC coolant.

Coolant Options for CNC Machines – Best Practices

When it comes to selecting a coolant for your CNC machines, there are several factors to consider to ensure optimal performance. From cooling effectiveness to cost and environmental impact, each aspect plays a role in choosing the right coolant for your needs.

First and foremost, it is crucial to select a coolant that is compatible with the material of your CNC machine. Different machines require different coolants to ensure optimal performance. Additionally, consider the specific cutting process and choose a coolant that is suitable for it.

Health and safety should also be a top priority when selecting a coolant. Ensure that the coolant meets all health and safety regulations to protect both operators and the environment.

One essential aspect to consider is the cooling effectiveness of the coolant. Look for a coolant that has high cooling capabilities, especially for high-speed machining operations. Cooling effectiveness plays a significant role in ensuring the longevity of your tools and the efficiency of the machining process.

Cost is another factor to keep in mind when choosing a coolant. Consider the long-term cost of the coolant, including maintenance and replacement, to determine its overall affordability.

Environmental impact is a growing concern in today’s world. Opt for a coolant that has minimal environmental impact to promote sustainability in your machining operations.

Regular coolant maintenance is crucial for optimal performance. Monitor the concentration of the coolant and adjust as needed. Controlling foam and ensuring proper foam control is also essential for the efficiency of the coolant.

By considering cooling effectiveness, cost, environmental impact, and maintenance, you can choose the best coolant options for your CNC machines. Remember to prioritize compatibility, safety, and sustainability to enhance the performance and reliability of your machining operations.

Choosing the Right CNC Coolant – Best Coolant Practices

When it comes to selecting the right CNC coolant for your machining needs, there are several factors to consider. By following best practices and considering key criteria, you can make an informed decision that maximizes performance and efficiency. Here’s a guide to help you choose the optimal CNC coolant.

Factors to Consider

- Machine Material: Different materials require different coolant properties. Ensure compatibility between the coolant and the machine material to avoid any negative effects.

- Cutting Process: Consider the specific cutting process (e.g., milling, turning, drilling) and choose a coolant that provides the necessary lubrication and cooling properties.

- Cooling Requirements: Evaluate the cooling needs of your operation. Some applications may require enhanced cooling capabilities, while others may prioritize chip removal.

- Health and Safety: Select a coolant with low toxicity and volatility to prioritize the well-being of operators and minimize potential health risks.

- Cost: Consider the overall cost of the coolant, including purchasing, disposal, and maintenance expenses, to ensure it aligns with your budget.

- Environmental Impact: Opt for a coolant with minimal environmental impact, such as low toxicity and biodegradability, to promote sustainability.

Additional Coolant Performance Criteria

In addition to the factors mentioned above, it’s important to evaluate the performance criteria of the coolant. Consider the following:

- Stability: Look for a coolant that maintains its properties over extended periods, promoting consistent performance.

- Foam and Mist Control: Choose a coolant that effectively manages foam and mist formation to maintain a clean and safe working environment.

- Odor Control: Opt for a coolant with odor control properties to ensure a pleasant working environment for operators.

- Absence of Undesirable Residues: Select a coolant that minimizes the formation of residues, preventing clogging and buildup within the machine.

- Long Fluid Life: Consider the longevity of the coolant. Choose a coolant that, with proper maintenance, offers an extended fluid life, reducing the frequency of replacements.

By considering these best practices and performance criteria, you can confidently select the ideal CNC coolant for your specific machining requirements, promoting efficiency, longevity, and environmental sustainability.

| Brand | Type | Key Features |

|---|---|---|

| Jancy Slugger | Synthetic Fluids | Excellent cooling capacity, corrosion prevention, easy maintenance |

| Sta-Lube | Semi-Synthetic Fluids | Good lubricity, low viscosity for moderate to heavy-duty applications |

| JEI | Soluble Oils | Water-based emulsion, good lubrication, heat transfer, rust resistance |

| Rustlick | Straight Oils | Good lubrication, rust prevention, poor cooling performance |

| Houghton | Synthetic Fluids | High-heat, high-velocity machining, corrosion prevention |

| Mobil | Semi-Synthetic Fluids | General-purpose, good lubricity |

| TRIM | Semi-Synthetic Fluids | Advanced bioresistance, long fluid life |

| Kool-All | Soluble Oils | Water-based emulsion, rust inhibition, low foam formation |

Recommended CNC Coolants for Different Applications

When it comes to CNC machining, choosing the right coolant is crucial for optimal performance and longevity. Fortunately, there are various CNC coolant brands available that offer a wide range of coolants designed for different applications. These coolants provide essential properties such as lubrication, cooling, and rust protection to support efficient machining operations. Some recommended coolant brands include Jancy Slugger, Sta-Lube, JEI, Rustlick, Houghton, Mobil, TRIM, and Kool-All.

Let’s take a closer look at these coolant brands:

- Jancy Slugger: Known for its high-quality coolant products that deliver exceptional performance in various metalworking processes.

- Sta-Lube: Offers an extensive range of coolant options suitable for different machining applications, ensuring reliability and performance.

- JEI: Provides versatile coolants that are compatible with a wide range of materials, offering excellent cooling and lubrication properties.

- Rustlick: Specializes in metalworking fluids that offer outstanding rust protection, lubrication, and cooling capabilities for optimal machining performance.

- Houghton: Offers a comprehensive range of metalworking fluids designed to enhance machining processes by providing exceptional cooling and lubrication.

- Mobil: Known for its advanced technology and innovative coolants that meet the highest industry standards, providing excellent performance and reliability.

- TRIM: Provides a wide variety of metalworking fluids and coolants that are specifically formulated to meet the diverse needs of CNC machining operations.

- Kool-All: Offers coolant solutions that are highly versatile and can be used in a wide range of metalworking applications, ensuring efficiency and productivity.

It is important to choose a coolant brand and type that aligns with your specific machining needs. Consider factors such as the type of material being machined, the cutting process, and the cooling requirements. Consulting with the manufacturer or their representative can help you make an informed decision and select the optimal coolant for your CNC machine.

Case Study: Rustlick Coolants in Automotive Machining

“We have been using Rustlick coolants in our automotive machining operations for over a decade, and we couldn’t be happier with the results. The coolants provide excellent lubrication, ensuring smooth cutting and reducing tool wear. They also have great cooling properties, preventing overheating and enhancing tool life. Additionally, Rustlick coolants offer superior rust protection, which is crucial for our machined components. We highly recommend Rustlick coolants for automotive machining applications.”

– John Thompson, Manufacturing Manager at XYZ Automotive

Coolant Maintenance – Ensuring Optimal Performance

Proper maintenance of CNC coolant is crucial for maintaining optimal performance and extending the lifespan of the coolant. By implementing regular maintenance practices, you can ensure that your coolant remains clean and effective throughout its usage.

One important aspect of coolant maintenance is monitoring the concentration of the coolant. Using a refractometer, you can regularly check the coolant concentration to ensure it remains within the recommended range. Maintaining the proper concentration is essential for effective cooling and lubrication during the machining process.

In addition to concentration monitoring, it’s important to maintain the pH balance of the coolant. Using pH testing strips, you can measure the acidity of the coolant and make any necessary adjustments. A balanced pH level helps prevent corrosion and ensures the coolant retains its effectiveness.

Another maintenance practice to consider is oil skimming. Implementing an oil skimming system helps remove contaminants such as tramp oil from the coolant. This not only improves the cleanliness of the coolant but also prevents bacterial growth, ensuring the coolant remains effective for a longer period of time.