CNC (Computer Numerical Control) machines are automated milling machines that are programmed by a computer program to carry out a particular task. They are equipped with pre-programmed software that can control the movement of the machine’s tool and the speed and direction of the cutting tool. CNC machines are used for a variety of machining operations, including drilling, milling, turning, and even cutting of materials. Milling machines, on the other hand, are manually operated machines that are used to create a variety of shapes and sizes in materials. They are equipped with a rotating cutting tool, usually a drill bit, that can move along three axes to cut and shape material into the desired shape.

Milling machines can be used for a variety of operations, including drilling, boring, reaming, and tapping. They can also be used to cut intricate shapes in materials, such as a keyway or a slot. In summary, the main difference between CNC machines and milling machines is that CNC machines are automated and are programmed to cut and shape materials with precision, while milling machines are manually operated and used to cut and shape materials with less precision.

A Comparison of CNC Machines vs. Milling Machines: What Are the Benefits of Each?

CNC (Computer Numerical Control) machines and milling machines are both used in the manufacturing industry, but they have several key differences. CNC machines are automated milling machines that are used to create highly accurate and precise parts and components. Milling machines are manual machines that rely on the strength and skill of the operator to produce parts and components accurately and with precision. CNC machines offer several benefits over milling machines. For one, CNC machines are highly accurate and can produce parts to tight tolerances. This is due to the fact that the machines are automated and are programmed with precise instructions. CNC machines also provide greater repeatability, meaning they can produce identical parts with the same measurements repeatedly.

Additionally, CNC machines are more efficient, as they can produce multiple parts quickly and with little operator input. Milling machines, on the other hand, offer several benefits of their own. For one, they are more cost effective as they are less expensive to purchase and maintain than CNC machines. Additionally, milling machines are more versatile, as they can be used to create more complex parts with special features such as slots and grooves. Milling machines are also capable of producing parts with a higher degree of detail, as they are operated manually by an experienced operator. Both CNC machines and milling machines offer their own benefits and drawbacks. CNC machines offer precise, automated production, while milling machines offer more cost-effective manual production. Ultimately, the choice between the two depend on the specific needs of the manufacturing project.

Exploring the Pros and Cons of CNC vs. Milling Machines for Your Business

CNC and milling machines are both essential tools for many businesses, but they have unique advantages and disadvantages that must be weighed when considering which route to take. This article will explore the pros and cons of both CNC and milling machines, so that business owners can make the best decision for their operations. CNC machines, or Computer Numerical Control machines, are automated tools that are programmed with specific instructions to produce parts or products. They are highly accurate and reliable, and can produce products with a high level of consistency. CNC machines are also much more efficient than manual milling machines and can often produce products faster. CNC machines can also be programmed to produce complex shapes and intricate designs that would be difficult to produce with manual machines.

Furthermore, CNC machines require less manual labor, meaning businesses can save money on labor costs. On the other hand, manual milling machines are still popular for certain applications and businesses. Manual machines offer a level of flexibility that CNC machines can’t match, as they allow for more creativity and experimentation. This can be beneficial for businesses that are looking to produce unique, one-of-a-kind products. Furthermore, manual milling machines tend to be much less expensive than CNC machines, meaning businesses can save money on upfront costs. In conclusion, when it comes to choosing between CNC and milling machines, it is important to consider the unique advantages and disadvantages of each. CNC machines offer a high level of accuracy and efficiency, but they can be expensive and inflexible. Manual milling machines offer more flexibility, but they require more manual labor and can be less accurate. Ultimately, the best decision for a business will depend on its individual needs and budget.

Understanding the Technical Differences Between CNC Machines and Milling Machines

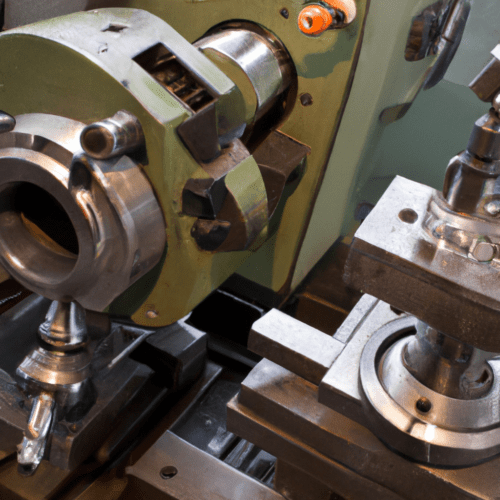

CNC machines and milling machines are both tools used in the manufacturing industry, but they have distinct technical differences that make them suitable for different tasks. CNC machines, short for Computer Numerical Control machines, are automated machines that are programmed using software to produce parts with extremely precise measurements and dimensions. CNC machines are typically used for producing large volumes of parts and products. They are typically equipped with cutting tools such as drills, routers, and lathes to cut, shape, and form materials. Milling machines, on the other hand, are manually operated machines that use a rotating cutting tool to shape and form materials. Milling machines are typically used for creating custom parts and components, and their designs can range from simple to highly complex depending on the application.

They are typically equipped with cutting tools such as drills, endmills, and taps to shape and form materials. The main technical difference between CNC machines and milling machines is that CNC machines are automated while milling machines are manually operated. This means that CNC machines can be programmed to produce a large number of parts with precise measurements and dimensions without the need for an operator, while milling machines require an operator to manually control the cutting tool and shape materials. Another technical difference is the type of cutting tools used. CNC machines are typically equipped with cutting tools such as drills, routers, and lathes, while milling machines are typically equipped with cutting tools such as drills, endmills, and taps. In conclusion, CNC machines and milling machines are both tools used in the manufacturing industry, but they have distinct technical differences that make them suitable for different tasks. CNC machines are automated and use cutting tools such as drills, routers, and lathes, while milling machines are manually operated and use cutting tools such as drills, endmills, and taps.

How to Choose the Right CNC or Milling Machine for Your Needs

When it comes to investing in a CNC or milling machine, there are several factors that must be taken into consideration. Depending on the intended use of the machine, different features and components are necessary. Therefore, it is important to understand the basic differences between the two types of machines in order to make an informed decision. CNC machines, or Computer Numerical Control machines, are automated machines that are programmable to produce components for a variety of industries. They are most commonly used in the manufacturing of parts such as metal components or plastic parts. The CNC machine is programmed with a series of commands that instruct the machine on how to cut and shape the desired material.

CNC machines are usually more expensive and require more experience to operate than milling machines, but they offer greater precision and a wider range of capabilities. Milling machines, on the other hand, are manually operated machines that are used to shape metal or other materials into different shapes or components. Unlike CNC machines, milling machines are not programmable and are generally used for simpler operations such as drilling, milling, and cutting. Milling machines are less expensive than CNC machines and require less skill to operate. When choosing between a CNC or milling machine, it is important to consider the intended use of the machine and the budget. CNC machines are more expensive and require more experience to operate, but offer greater precision and a wider range of capabilities. On the other hand, milling machines require less skill and are less expensive, but offer less precision and fewer capabilities. Knowing the intended use of the machine and the budget will help to determine which type of machine is the best option for the job.

Exploring the Advantages of Automation with CNC Machines vs. Milling Machines

The use of automation in industrial manufacturing processes has become increasingly popular over the years due to its many advantages. One such form of automation is the use of CNC machines and milling machines. While both are used for various purposes, CNC machines offer a number of advantages over milling machines. CNC machines, also known as Computer Numerical Control machines, are automated precision machines that can be programmed to produce identical parts with high level of accuracy. They are highly efficient and can produce a large number of identical parts in a short amount of time. Unlike milling machines, which are manual and operated by hand, CNC machines are fully automated and require minimal human intervention. This allows for faster production of more precise parts in larger quantities. Unlike milling machines, which are limited to a single workpiece, CNC machines can be used to produce multiple parts simultaneously. This makes them ideal for mass production. The high level of precision also ensures that the parts produced are consistent in quality and accuracy.

Additionally, CNC machines are easier to maintain and require less manual labour than milling machines. CNC machines are also more reliable as they are not prone to human errors. With repetitive tasks, CNC machines can produce identical parts with the same accuracy each time. This helps to reduce waste and increase productivity. Furthermore, CNC machines are more cost effective than milling machines as they require less labour and produce higher quality and more consistent parts in less time. Overall, CNC machines offer a number of advantages over milling machines. The use of CNC machines has revolutionized the industrial manufacturing process by providing faster and more accurate production of parts. With their high level of precision and efficiency, CNC machines are an essential part of the modern manufacturing process.