Facing and turning are two distinct machining operations in metalworking, each serving a specific purpose. Facing involves cutting the end of a workpiece perpendicular to its axis of rotation, creating a flat surface. This process is typically used to achieve precise lengths, improve surface finish, or prepare the workpiece for further operations. Turning, on the other hand, is the process of removing material from the outer diameter of a rotating cylindrical workpiece.

It’s used to reduce the workpiece’s diameter, create tapers, or form contours along its length. While both operations use similar tools and machines, such as lathes, their primary difference lies in the direction of the cutting tool’s movement: facing cuts across the end of the workpiece, while turning cuts along its length. Understanding these differences is crucial for machinists to select the appropriate technique for achieving desired part specifications and geometries in manufacturing processes.

- Facing and turning are fundamental machining processes that play a critical role in shaping and finishing metal components.

- Facing is typically used to create a flat surface on the end or sides of a cylindrical workpiece, while turning reshapes the outer diameter to reduce its size and create a round shape.

- The primary difference between facing and turning lies in the direction of the feed in relation to the workpiece axis.

- Both facing and turning involve the use of lathes and CNC machines, allowing for precise material removal and part shaping.

- Selecting the appropriate tools, feed rates, and cutting conditions can optimize machining efficiency and component quality in both facing and turning operations.

Introduction to Machining Processes: Turning and Facing Explained

Machining processes such as turning and facing play a crucial role in the manufacturing industry by shaping and finishing components to their required specifications. Turning is a versatile machining process used to produce external cylindrical surfaces parallel to the workpiece axis, while facing is used to generate surfaces perpendicular to the workpiece axis, typically to create a flat end on a cylindrical part. Detecting the difference between these methods relies on understanding the material rotation, cutting tool movement, and the process specifics, whether performed manually or utilizing CNC techniques for added precision and automation.

Both turning and facing are vital machining processes that serve different purposes in shaping workpieces. To gain a better understanding, let us explore these processes in greater detail:

| Process | Description | Tool Movement | Workpiece Axis | Associated Processes |

|---|---|---|---|---|

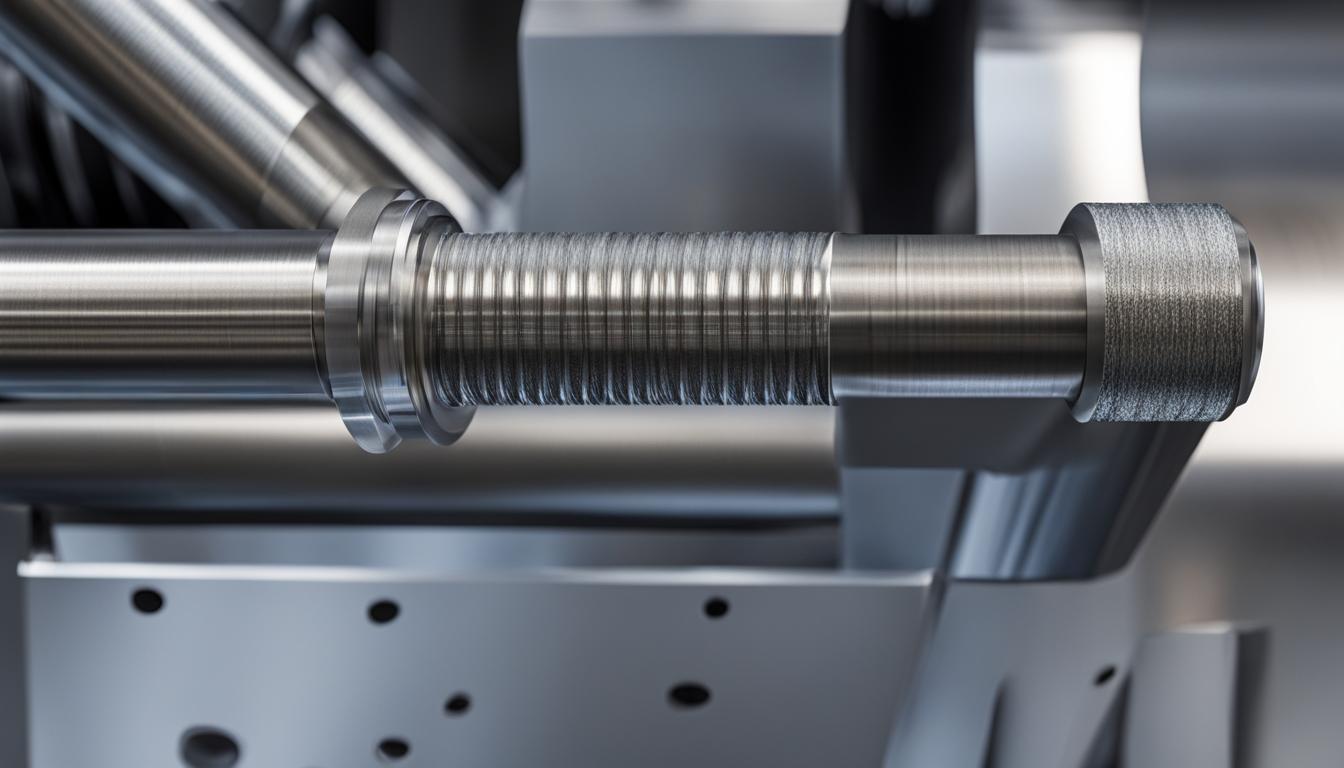

| Turning | A machining process that removes material from the external surface of a rotating workpiece to produce cylindrical components. | Parallel to the axis of rotation | Workpiece axis is horizontal or vertical, depending on the lathe type | Grooving, tapering, threading |

| Facing | A machining process that creates a flat end face on a cylindrical workpiece by removing material using a cutting tool. | Perpendicular to the axis of rotation | Workpiece axis is typically horizontal | Smooth finishing, preparing workpiece for further operations |

In both processes, the workpiece is held securely in a chuck or between centers and rotated at a controlled speed. The difference lies in the direction of the cutting tool movement and the part of the workpiece being machined. In turning, the cutting tool moves along the outer diameter of the workpiece, parallel to its axis, while in facing, the tool moves perpendicular to the axis, working on the end face of the workpiece.

Facing and turning operations usually require compatible lathe machines, with specific tooling and settings depending on the material being machined and the level of precision desired. The adoption of CNC techniques has revolutionized these processes, allowing for greater precision, repeatability, and efficiency.

Understanding the distinctions between facing and turning, alongside the unique attributes of each process, enables informed decision-making for the most effective machining approach. As the manufacturing industry aspires to create seamless, perfectly-crafted components, mastering both techniques remains a crucial skill for machinists and engineers.

The Basics of Facing in Lathe Machine Operations

Facing in the context of machining is the process of creating a smooth, flat surface on the end of a workpiece, such as the end of a cylinder, by using a cutting tool on a lathe or milling machine. The cutting tool is typically positioned perpendicular to the workpiece’s axis of rotation. During the facing operation on a lathe, the workpiece, which is clamped in the headstock, is rotated while the tool is fed across the surface to remove material until the desired surface finish and dimension are achieved.

What Does Facing Mean in the Machining Context?

From a facing definition perspective, facing can be explained as another crucial step in the machining process, specifically for creating flat surfaces in the workpiece. The term facing refers to the removal of material from the workpiece’s end to produce smooth surfaces, either at the end of a cylinder or the sides or edges of a part. This flat surface is achieved by using a cutting tool on a lathe, with the tool placed perpendicular to the part’s rotational axis.

How to Perform Facing Operations on a Lathe

Facing off lathe operations involve an organized approach to ensure precision and desired results. As a result, the process entails the following steps:

- Securely clamp the workpiece in the headstock of the lathe.

- Select the appropriate cutting parameters, such as feed and speed settings, based on the workpiece material, the required surface finish, and accuracy.

- Mount a suitable facing tool into the tool holder to ensure optimal cutting performance.

- As the workpiece rotates, slowly move the cutting tool perpendicular to the rotational axis of the workpiece. This process often uses the lathe’s cross slide to maintain precision and control.

- Depending on the requirements of the task at hand, operators can choose between hand feeding or power feeding, which impacts the surface finish.

- Make necessary adjustments to the spindle speed and tool movement depending on desired results, either by moving from the center to the edge or from the edge towards the center of the workpiece.

Performing a successful facing operation on a lathe machine ultimately comes down to adhering to these outlined steps, ensuring precise control over the cutting parameters, and having a keen understanding of the specific workpiece and material at hand.

Demystifying Turning: What Does Turning Mean in Manufacturing?

In manufacturing, turning refers to a machining process designed to produce cylindrical components where the cutting tool removes material from the external surface of a rotating workpiece. The tool moves parallel to the axis of rotation, effectively resizing or reshaping the workpiece to achieve required dimensions and tolerances.

Turning operations can create a variety of features, including threads, tapers, and various geometric shapes on the workpiece. These operations are performed on a lathe with the use of different cutting tools. This versatility is one of the reasons why turning and facing are essential aspects of machining work.

To better understand the turning process, it is helpful to consider some of the standard steps that machinists follow. These include:

- Securing the workpiece within the lathe.

- Selecting the appropriate cutting tool and mounting it onto the lathe’s tool holder.

- Setting the proper speed and feed rate based on the workpiece material and desired surface finish.

- Moving the cutting tool parallel to the axis of rotation, following the desired turning path.

- Continuously monitoring the lathe to ensure accuracy and make adjustments as necessary.

When compared with facing operations, turning operations share some similarities. Both require a lathe and cutting tools. However, the main difference between them lies in the movement of the cutting tools and the part of the workpiece that is machined. In turning, tools move parallel to the workpiece’s axis, modifying the cylindrical outer surface. On the other hand, facing focuses on the end face, with tools moving perpendicular to the axis.

| Turning Process | Facing Process |

|---|---|

| Cutting tool moves parallel to the axis of rotation | Cutting tool moves perpendicular to the axis of rotation |

| Resizes or reshapes the external surface of the workpiece | Creates a smooth, flat end surface on the workpiece |

| Used for creating threads, tapers, and geometric shapes | Used for producing flat surfaces or preparing the workpiece for further operations |

Understanding the turning definition and knowing how to do turning are crucial for machinists and manufacturers who want to produce high-quality, precisely shaped components. By mastering the art of turning and facing operations, professionals in the machining industry can create a wide range of parts and ensure optimal efficiency within their manufacturing processes.

Comparing Facing vs Turning: Key Distinctions in Machining

The primary distinctions between turning and facing operations in machining relate to the direction of tool movement and the part of the workpiece being machined. Turning involves the cutting tool moving parallel to the workpiece’s axis, focusing on the cylindrical outer surface, while facing targets the end face, with the tool moving perpendicular to the axis. The differences extend to the cutting conditions, such as constant cutting speed for turning and variable speed in facing operations. Understanding when to apply each method is essential for the production of precise components.

Defining the Difference Between Turning and Facing Operations

| Parameter | Turning | Facing |

|---|---|---|

| Tool Movement | Parallel to the workpiece’s axis | Perpendicular to the workpiece’s axis |

| Part of Workpiece Machined | Cylindrical outer surface | End face |

| Cutting Speed | Constant | Variable |

When to Use Facing Over Turning in Machining Tasks

The decision to use facing over turning in machining tasks depends on the feature needing to be machined. Facing is the preferred method when a flat end surface is required or to prepare the end of the workpiece for subsequent operations, such as drilling or boring. Conversely, turning is chosen to resize the workpiece’s diameter or to create external features like grooves and threads along the length of the cylindrical piece. Manufacturers must consider the desired outcome, part geometry, and required precision when selecting between these operations.

- Use Facing: When a flat end surface is required or to prepare the end of the workpiece for subsequent operations, such as drilling or boring.

- Use Turning: To resize the workpiece’s diameter or to create external features like grooves and threads along the length of the cylindrical piece.

How Cutting Tool Dynamics Affect Facing and Turning

The dynamics of cutting tools have a significant impact on the quality and precision of metal facing and turning operations on a lathe or a CNC machine. Various factors, such as tool material, geometry, lead angle, and edge angle, play a significant role in determining the cutting forces, tool life, and surface finish of the manufactured products.

Tool selection is critical to machining efficiency and effectiveness. The choice should be guided by cutting tool dynamics, which encompasses various factors such as:

- Tool material (high-speed steel, carbide, ceramic, etc.)

- Tool geometry (shape and dimensions of the cutting edge)

- Lead angle (angle between the tool’s cutting edge and the workpiece surface)

- Edge angle (angle between the tool’s cutting edge and the tool holder)

These factors affect the cutting forces, tool life, and surface finish of the finished products. A proper balance must be struck between them to ensure optimal manufacturing performance.

| Tool Material | Pros | Cons |

|---|---|---|

| High-speed steel (HSS) | Good toughness, low cost | Lower tool life, limited cutting speeds |

| Carbide | High cutting speeds, long tool life | More brittle, higher cost |

| Ceramic | Excellent wear resistance, high-speed capabilities | Very brittle, sensitive to interruptions in cut |

Besides tool selection, the stability of cutting tools during the machining process is essential for maintaining precision and minimizing defects. An overhanging tool might induce unwanted vibrations that can affect the final product’s surface finish and dimensional accuracy.

Additionally, cutting conditions such as speed, feed rate, and depth of cut must be adequately set to minimize deflection and chatter, which can deteriorate the quality of facing and turning. For example, excessive cutting depths can cause high cutting forces, increasing the risk of undesirable vibrations or even tool breakage. On the other hand, insufficient cutting depths can result in poor surface finish and reduced productivity.

In conclusion, cutting tool dynamics play a crucial role in optimizing facing and turning operations’ performance. By carefully considering the factors discussed above and adjusting machining parameters accordingly, manufacturers can achieve enhanced quality, precision, and efficiency in their metalworking processes.

Optimizing Machining Efficiency: Facing and Turning Parameters

Optimizing efficiency in facing and turning operations demands careful attention to machining parameters such as speed, feed, depth of cut, and tool geometry. The primary objective is to strike the right balance between metal removal rates, tool life, and surface finish – achieving minimal machining costs while maximizing production. In this section, we’ll discuss the significance of workholding methods, rigidity of setups, and machine component alignments, as well as the variances in facing and turning processes.

Key Parameters for Efficient Machining

The efficiency of both facing process in lathe machine and turning operations can be significantly enhanced by optimizing several key parameters:

- Speed: Spindle speed influences the surface finish and tool life. In facing operations, slower spindle speeds are often required as the tool approaches the center of the workpiece, while turning typically involves constant spindle speeds.

- Feed: The rate at which the cutting tool advances into the workpiece affects material removal, surface finish, and machining time.

- Depth of cut: Adjusting the amount of material removed in a single pass allows for efficient metal removal without overburdening the cutting tool or workpiece.

- Tool geometry: Selecting the appropriate cutting edge, relief angle, and rake angle for the tool can improve cutting performance and tool life.

Workholding Methods, Set-Up Rigidity, and Alignment

Choice of workholding methods, the rigidity of the set-up, and machine component alignments are critical factors in achieving the required accuracy and eliminating potential issues like chatter and vibration during the facing operation and turning processes. Various options for workholding include chucks, collets, and faceplates, chosen based on the workpiece’s size and shape, as well as the specific machining requirements.

An effective set-up maintains rigidity and minimizes vibration. Reinforcing weak points with supports, clamping the workpiece securely, and using appropriate tool holders contribute to a stable environment conducive to accurate machining. Precise alignment of machine components, including workpiece balancing and tool setting, is crucial for producing quality parts.

Varying Parameters for Facing and Turning Processes

While both facing process in lathe machine and turning rely on the same basic parameters, there are distinct differences in their methods. Facing operations typically require adjustments in spindle speed as the tool moves toward the workpiece’s center, as well as considerations for a variable cutting speed throughout the operation. In contrast, turning processes commonly maintain constant cutting speeds and other parameter settings to achieve accurate and repeatable results.

By carefully optimizing all these parameters for each specific facing and turning operation, machinists and manufacturers can ensure that they achieve the best possible balance of efficiency, tool life, and part quality, ultimately maximizing their production and minimizing costs.

Facing Off on a Lathe: Process, Tools, and Techniques

The process of facing off on a lathe involves a series of steps to create a smooth, flat surface on a cylindrical workpiece. This operation is widely used in machining for tasks like shortening the workpiece or preparing it for drilling or other machining processes. It is essential to follow a systematic procedure of facing using a lathe machine to ensure precision and quality.

- Secure the workpiece: Depending on the task at hand, mount the workpiece either in a chuck or between centers to hold it firmly in place during the facing operation.

- Select the facing tool: Choose a facing off tool based on the workpiece material and required surface finish. The tool must have the correct geometry for efficient material removal and a long tool life.

- Set the correct tool height: Position the cutting tool at an appropriate height in the tool holder for optimal performance and surface quality. The tool’s tip must be at the same height as the center of the workpiece.

- Choose the lead angle: Depending on the size, shape, and required finish of the workpiece, select a suitable lead angle for the cutting tool.

- Configure the feed and speed settings: Set the appropriate feed rate and spindle speed for the facing turning process, considering factors such as workpiece material and desired surface finish.

- Perform the facing operation: As the workpiece rotates, move the cutting tool across the end surface, either manually or with power feed, to remove material and create a flat, smooth face.

- Check the final surface: Ensure that the end surface meets the desired finish and dimension requirements by using measuring tools and visual inspection.

In addition to mastering the basic facing operation on lathe machine procedure, it is essential to maintain the lathe, cutting tools, and machine setup to ensure consistent and precise results. Implementing the right tools and techniques while adhering to the procedure will lead to improved efficiency and a quality finished product.

The Role of CNC Machines in Facing and Turning

Computer Numerical Control (CNC) machines have revolutionized the world of machining, greatly impacting the efficiency and precision of facing and turning operations. CNC machines offer significant benefits over manual machining processes, including enhanced accuracy, repeatability, and the ability to produce complex components.

Understanding the Importance of CNC Machining in Modern Manufacturing

CNC machining is indispensable in industries such as aerospace, automotive, and medical device manufacturing where high levels of precision and complex geometries are required. By replacing the reliance on manual adjustments, CNC machines can execute detailed sequences for a broad range of operations, streamlining production processes and reducing overall machining time.

One of the major strengths of CNC machines is their ability to seamlessly transition between facing on lathe and turning operations. This not only increases the efficiency of the machining process but also significantly boosts the quality of the manufactured parts, greatly enhancing their performance and lifespan.

Benefits of CNC machining in facing and turning operations:

- Precision and accuracy in material removal and surface finish

- Improved repeatability and consistency across large production runs

- Ability to handle complex geometries and intricate designs

- Reduced reliance on manual adjustments, minimizing human error

- Enhanced flexibility in transitioning between different machining operations

The adoption of CNC machines in facing in lathe and engineering turning has transformed the machining landscape, enabling manufacturers to deliver high-quality, precision-engineered components that meet increasingly stringent demands for performance, durability, and aesthetics.

| Manual Machining | CNC Machining |

|---|---|

| Limited precision and consistency | High precision and repeatability |

| Difficulty in handling complex geometries | Capability to produce intricate designs |

| Higher reliance on operator skill and experience | Reduced dependence on manual adjustments |

| Slower production rates | Faster and more efficient machining processes |

With CNC machines playing a vital role in modern manufacturing, mastering the art of lathe facing operation and turning has become essential for machinists and engineers looking to stay competitive in a rapidly evolving industry landscape. By embracing CNC technology, manufacturers can unlock unparalleled levels of efficiency, precision, and reliability in their machining processes, driving innovation and ensuring the successful production of high-quality components.

Conclusion: Choosing Between Facing and Turning for Your Machining Project

When deciding between facing and turning for a machining project, it is crucial to consider the component requirements, precision levels, and desired surface finishes. While both operations are fundamental in the machining industry, their application is determined by the unique specifications of the task at hand. Manufacturers and machinists must weigh the advantages and purposes of each process to create high-quality, machined products with optimal geometric features and functional attributes.

Understanding the differences between facing and turning, such as the direction of tool movement and the part of the workpiece being machined, allows manufacturers to select the most suitable process for their specific project. Facing, which focuses on the end face of the workpiece, is ideal for creating flat surfaces or preparing the workpiece for additional operations. In contrast, turning is best suited for resizing the workpiece’s diameter or crafting external features like grooves and threads along the length of a cylindrical piece.

Modern advancements in CNC machines have revolutionized both facing and turning operations, providing automated control, precision, and repeatability. This technology enables seamless transitioning between the two processes, optimizing production rates and reducing manual adjustments. In conclusion, when selecting between facing and turning, it is essential to consider the desired outcome, part geometry, and required precision to successfully complete your machining project.