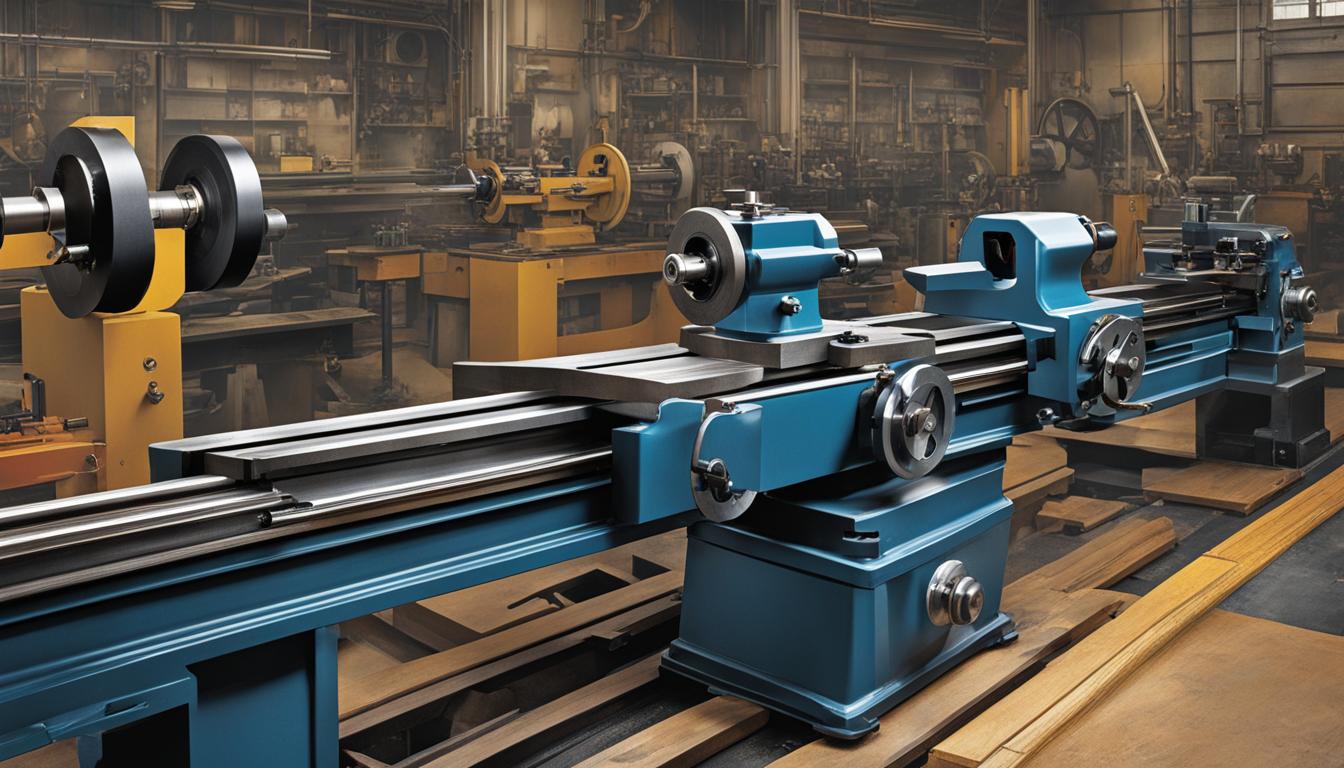

The primary difference between a lathe and a shaper lies in their operational mechanisms and the types of workpieces they process. A lathe is a machine tool that rotates the workpiece on its axis to perform various operations such as cutting, sanding, knurling, drilling, or deformation, while a shaper uses a single-point cutting tool to machine a flat surface on a workpiece. Lathes are typically used for creating cylindrical or conical shapes, with the workpiece rotating against a stationary cutting tool. In contrast, shapers employ a reciprocating motion of the cutting tool across a stationary workpiece, making them ideal for producing flat surfaces, grooves, and slots.

Lathes are more versatile and can handle a wider range of operations, including both internal and external machining, whereas shapers are limited to external surface machining. Additionally, lathes generally offer higher precision and are better suited for mass production, while shapers are more commonly used for smaller batch sizes or specialized applications where flat surfaces are required. The choice between a lathe and a shaper depends on the specific machining requirements, the shape of the workpiece, and the desired end product.

- A lathe rotates a workpiece to perform various operations, while a shaper uses linear motion to create linear toolpaths on a workpiece.

- Lathes are used for creating cylindrical and tapered parts, as well as complex shapes, while shapers are used for creating flat and straight surfaces.

- Shapers are better for producing simple shapes and cuts, while lathes offer more versatility and the ability to create intricate patterns and shapes.

- The choice between a lathe and a shaper depends on your specific application and requirements.

- Understanding the differences between lathe and shaper machines will help you make an informed decision in your machining processes.

What is the difference between shaper and planer?

A shaper and a planer are both machine tools used for shaping and finishing workpieces. However, there are key differences between the two in terms of their cutting motion and the types of workpieces they are best suited for.

One of the main differences between a shaper and a planer is the cutting motion they employ. A shaper uses a reciprocating motion to cut the material, while a planer uses a rotating motion. This difference in cutting motion affects the types of surfaces and shapes that can be produced. A shaper is primarily used for producing flat surfaces and cutting slots, while a planer is better suited for shaping large flat surfaces and cutting grooves.

Another difference between the two machines is the size of the workpieces they can handle. Shapers are generally used for smaller workpieces, while planers are designed for larger workpieces. This difference in size capacity makes planers more suitable for tasks that require machining larger surfaces or removing larger amounts of material.

To summarize, the main differences between a shaper and a planer lie in their cutting motion, the types of surfaces and shapes they can produce, and the size of the workpieces they are best suited for.

Table: Comparison between Shaper and Planer

| Aspect | Shaper | Planer |

|---|---|---|

| Cutting Motion | Reciprocating | Rotating |

| Surface Types | Flat surfaces, slots | Large flat surfaces, grooves |

| Workpiece Size | Smaller | Larger |

What is a milling machine?

A milling machine is a versatile machine tool used in the machining process to shape and finish metal and other solid materials. It operates by using a rotating cutting tool to remove material from the workpiece, creating complex shapes, contours, and precise cuts. Milling machines are essential in industries such as automotive, aerospace, and manufacturing, where precision and intricate patterns are required.

Compared to a lathe or a shaper machine, milling machines offer greater versatility and the ability to create more intricate designs. While lathes primarily rotate the workpiece to perform various operations, milling machines can perform a range of functions such as drilling, boring, reaming, tapping, and threading in addition to shaping and cutting. This makes milling machines suitable for a wide variety of applications and allows for the production of parts with high precision.

A key difference between a milling machine and a shaping machine is the cutting motion. While a shaper machine uses a reciprocating motion to cut the material, a milling machine uses a rotating motion. This enables the milling machine to perform more precise and complex operations, making it a preferred choice for many manufacturing processes.

| Milling Machine | Shaper Machine |

|---|---|

| Rotates cutting tool | Uses reciprocating motion to cut |

| Performs a variety of operations | Mainly used for shaping flat surfaces |

| Creates complex shapes and contours | Produces flat and straight surfaces |

In summary, a milling machine is a powerful tool used in various industries for shaping and finishing materials with precision. Its ability to perform multiple operations and create complex shapes makes it a valuable asset in manufacturing processes. Compared to a shaper machine, a milling machine offers more versatility and the ability to produce intricate designs and patterns.

What does a shaper machine do?

A shaper machine is a versatile machine tool that is primarily used for shaping and machining various materials, including metal, wood, and plastic. It employs a reciprocating motion to move a single-point cutting tool across the surface of the workpiece, allowing for precise shaping and contouring. The cutting tool, which can be a chisel or a milling cutter, removes material from the workpiece, creating flat surfaces, contours, and other desired shapes.

The main advantage of a shaper machine is its ability to produce flat surfaces and intricate shapes with high precision. It is commonly used in industries such as automotive, aerospace, and manufacturing for tasks such as creating keyways, cutting slots, and producing complex profiles. The shaper machine is especially useful when working on smaller workpieces that require detailed shaping and machining.

It’s essential to note that a shaper machine is different from a cutting tool. While a cutting tool is a handheld instrument used for cutting and shaping materials manually, a shaper machine is a dedicated machine tool that performs specific shaping tasks with greater accuracy and efficiency.

Advantages of a Shaper Machine:

- Precision shaping and machining of flat surfaces and intricate shapes

- Ability to work on smaller workpieces with high accuracy

- Versatility in material compatibility, including metal, wood, and plastic

- Wide range of applications in various industries

Safety Precautions in a Lathe Machine Shop

When working with a lathe machine, safety should always be the top priority to prevent accidents and protect the well-being of personnel. Here are some essential safety precautions to follow in a lathe machine shop:

1. Personal Protective Equipment (PPE)

- Wear safety glasses or goggles to protect the eyes from flying debris.

- Use earplugs or earmuffs to reduce exposure to loud noise.

- Wear appropriate clothing to protect against sparks, oil, and other hazards.

- Ensure that long hair is tied back and loose jewelry is removed.

2. Machine Guarding

- Ensure that the lathe machine is properly guarded to prevent accidental contact with moving parts.

- Never operate the lathe machine with the guards removed or compromised.

- Inspect the guards regularly for any damage or wear and replace them if necessary.

3. Housekeeping

- Keep the work area clean and free of clutter to prevent slips, trips, and falls.

- Regularly remove chips, swarf, and other debris from the lathe machine and the floor.

- Dispose of oily rags and other flammable materials in designated containers.

4. Machine Maintenance

- Follow the manufacturer’s instructions for the proper maintenance and lubrication of the lathe machine.

- Inspect and clean the machine regularly to ensure its safe and efficient operation.

- Report any malfunctioning or damaged parts to the supervisor or maintenance personnel immediately.

5. Training and Supervision

- Provide proper training to all personnel who operate or work around the lathe machine.

- Ensure that operators are familiar with the lathe machine’s safety procedures and protocols.

- Supervise the operation of the lathe machine to ensure safe practices are followed at all times.

By adhering to these safety precautions, a lathe machine shop can create a safe working environment where accidents and injuries are minimized. Remember, safety is everyone’s responsibility, and it is essential to prioritize it in all aspects of lathe machine operations.

What is the Difference Between CNC and Lathe?

When it comes to machining processes, two commonly used tools are CNC (Computer Numerical Control) machines and lathes. While they both play a crucial role in shaping and forming workpieces, there are distinct differences between them.

A lathe is a machine tool that is operated manually by the user. It involves rotating a workpiece against a cutting tool to create desired shapes. Lathes are known for their versatility and ease of use, making them suitable for various applications. On the other hand, CNC machines are operated by computer programs that control the movements and operations of the machine. This automation allows for higher precision, faster production rates, and the ability to create intricate designs and shapes.

Main Differences Between CNC and Lathe:

To better understand the contrast between CNC machines and lathes, let’s summarize their main differences:

| CNC Machines | Lathes |

|---|---|

| Operated by computer programs | Operated manually by the user |

| Higher precision | Less precision compared to CNC machines |

| Ability to create complex shapes and designs | Primarily used for turning operations and creating cylindrical parts |

| Faster production rates | Slower production rates compared to CNC machines |

While CNC machines offer advanced capabilities and are well-suited for intricate projects, lathe machines still hold their ground due to their versatility and user-friendly nature. The choice between the two depends on the specific requirements of the project and the desired outcome.

What is the difference between turning and a lathe?

Turning is a machining process that involves shaping a workpiece on a lathe machine by rotating it against a cutting tool. A lathe, on the other hand, is the machine used to perform turning operations. While turning refers to the process itself, a lathe is the tool used to carry out the turning process.

A lathe consists of several main parts, including the headstock, tailstock, carriage, and tool post. The headstock holds the workpiece and provides the rotational motion, while the tailstock supports the other end of the workpiece. The carriage moves along the lathe’s bed and holds the cutting tool, allowing it to move across the workpiece to shape it. The tool post holds and positions the cutting tool, enabling precise machining operations.

In terms of differences between turning and a lathe, turning is the action of shaping a workpiece by rotating it against a cutting tool, whereas a lathe is the machine specifically designed for turning operations. The lathe’s main parts work together to facilitate the turning process and allow for the creation of cylindrical parts, tapered parts, and complex shapes.

Difference between turning and a lathe:

| Turning | Lathe |

|---|---|

| Shaping a workpiece on a lathe by rotating it against a cutting tool. | The machine tool used to perform turning operations. |

| Process itself | Machine used for turning |

| Rotating the workpiece | Headstock, tailstock, carriage, and tool post |

| Creates cylindrical parts, tapered parts, and complex shapes | Facilitates the turning process and enables precise machining operations |

Overall, turning and a lathe are closely related, with turning being the action of shaping a workpiece and a lathe being the machine that enables that action. The lathe’s main parts work together to provide the necessary rotational and cutting motion for turning operations, allowing for the creation of a wide range of shapes and contours.

Why is a Lathe Not a Machine?

A lathe is a tool used in machining processes, but it is not considered a machine in the traditional sense. Unlike machines, a lathe does not have any moving parts, motors, or power sources. Instead, it is a manual tool that is operated by the user to rotate the workpiece and shape it using a cutting tool. The term “machine” typically refers to a device or apparatus that utilizes automated processes, controls, and power sources to perform tasks. In contrast, a lathe relies entirely on the skill and control of the operator.

The distinction between a tool and a machine lies in their capabilities and functions. A tool is a handheld or manually operated instrument used to perform a specific task or operation, while a machine is a complex apparatus that automates and simplifies various processes. In the case of a lathe, it is a tool because it is a handheld device operated by the user to shape and form materials.

It is important to note that while a lathe may not be classified as a machine, it is a crucial tool in many industries such as metalworking, woodworking, and manufacturing. It allows artisans and machinists to create precise shapes, contours, and threads on workpieces. Whether it is used for turning cylindrical parts or crafting intricate designs, the lathe remains a versatile and valuable tool in the hands of skilled craftsmen.

Table: Difference Between Lathe and Machine

| Criteria | Lathe | Machine |

|---|---|---|

| Power Source | Manually operated | Automated with motors and power sources |

| Motion | Rotates the workpiece | Utilizes various motions depending on the operation |

| Operational Control | Dependent on the skill and control of the operator | Controlled by automated processes and controls |

| Capability | Used for shaping and forming workpieces | Performs a wide range of tasks using automation |

In conclusion, while a lathe is not classified as a machine, it is an essential tool in many industries for shaping and forming materials. Its manual operation and reliance on the skill of the operator distinguish it from automated machines. However, a lathe’s versatility and ability to create precise shapes make it a valuable asset in the hands of skilled craftsmen.

Which is Better, Planer or Shaper Machine?

When it comes to choosing between a planer and a shaper machine, the decision ultimately depends on the specific application and requirements. Both machines have their own unique strengths and applications, making them suitable for different machining tasks.

A planer machine is particularly well-suited for removing large amounts of material quickly and efficiently. It excels at shaping large flat surfaces and cutting grooves, making it an ideal choice for projects that require extensive material removal. With its robust construction and powerful cutting capabilities, a planer machine is commonly used in heavy-duty industries.

On the other hand, a shaper machine is better suited for creating precise shapes and cuts, and for working on smaller workpieces. It is particularly useful for producing flat surfaces, cutting slots, and creating simple shapes. With its versatility and ability to achieve intricate details, a shaper machine is often favored in industries that require precision and fine craftsmanship.

Differences between Planer and Shaper Machines

To further understand the differences between planer and shaper machines, let’s take a closer look at some key factors:

| Factors | Planer Machine | Shaper Machine |

|---|---|---|

| Cutting Motion | Rotating motion | Reciprocating motion |

| Material Removal | Removes large amounts of material quickly | Removes material with precision and control |

| Workpiece Size | Large workpieces | Smaller workpieces |

| Applications | Shaping large flat surfaces, cutting grooves | Producing precise shapes, cutting slots |

As seen in the table above, planer machines excel at removing large amounts of material quickly, making them ideal for shaping large workpieces. Shaper machines, on the other hand, are better suited for producing intricate shapes and cuts on smaller workpieces. Ultimately, the choice between a planer and a shaper machine depends on the specific machining requirements and the desired outcome of the project.

In Summary

Choosing between a planer and a shaper machine requires careful consideration of the specific machining needs. If the project involves shaping large surfaces and removing significant amounts of material, a planer machine may be the better choice. However, if precision and intricate detailing are paramount, a shaper machine may be the more suitable option. Both machines have their own unique strengths and applications, and the decision should be based on the specific requirements of the project at hand.

What is a Lathe Tool?

A lathe tool is an essential component of a lathe machine and is used to shape and form a workpiece. It is a cutting tool that removes material from the workpiece to create the desired shape and size. The lathe tool is typically made of high-speed steel or carbide and is held securely in a tool holder mounted on the carriage of the lathe machine.

Lathe tools come in various shapes and sizes, depending on the specific task and the material being worked on. Some common types of lathe tools include turning tools, parting tools, threading tools, and boring tools. Each type of tool is designed to perform a specific operation, such as turning the outside or inside diameter of a workpiece, cutting threads, or creating holes.

The lathe tool is advanced along the workpiece by adjusting the position of the carriage. The cutting edge of the tool comes into contact with the workpiece, and as the lathe rotates the workpiece, the tool removes material to create the desired shape. The precision and skill of the operator are crucial in achieving accurate and smooth cuts with the lathe tool.

Difference between a Tool and a Machine

It is important to distinguish between a tool and a machine when discussing lathe tools. A tool is a handheld implement or device used to carry out a specific function, such as cutting, shaping, or fastening. It is typically operated manually and requires the physical effort of the user to perform the desired task.

On the other hand, a machine is a mechanical device that uses power to perform various tasks. It is typically automated and can carry out complex operations with precision and efficiency. A lathe machine, for example, utilizes a tool (lathe tool) to shape and form a workpiece, but it is the machine itself that provides the power and controls the movement of the tool.

In summary, a lathe tool is a handheld cutting implement used in conjunction with a lathe machine to shape and form a workpiece. It is an essential component of the lathe machine and allows for precise and controlled material removal.

History and Usage of Shaper Machines

Shaper machines have a rich history dating back to the mid-19th century. They were widely used in industrial production until the mid-20th century. The invention of the shaper machine is credited to James Nasmyth in 1836, although earlier versions were developed by Samuel Bentham between 1791 and 1793.

During their prime, shaper machines played a vital role in shaping and machining workpieces. They were commonly used for producing flat surfaces, cutting slots, and creating simple shapes. However, with advancements in technology, shaper machines have been largely superseded by other machine tools like milling machines and grinding machines.

Despite this, shaper machines still find their place in various machine shops. They are particularly useful in jobbing shops and tool and die shops. Shaper machines remain cost-effective for producing small batches or individual pieces. Moreover, they hold significant appeal for hobbyist machinists due to their simplicity and retro charm.