Before purchasing a CNC router machine, it’s crucial to consider several key factors that will impact your decision and ensure you select the right equipment for your needs. The machine’s size and working area should align with your project requirements, while the power and spindle speed will determine the materials you can work with and the cutting precision. Evaluate the machine’s construction quality, including the frame and components, to ensure durability and longevity.

The control system and software compatibility are essential for ease of use and integration with your existing workflow. Consider the machine’s accuracy and repeatability, as these factors directly affect the quality of your output. Noise levels and dust collection capabilities are important for workplace comfort and safety.

Assess the available support and warranty options from the manufacturer or supplier. Budget not only for the initial purchase but also for ongoing maintenance, tooling, and potential upgrades. Research the machine’s learning curve and training requirements to ensure you can operate it effectively. Finally, consider the machine’s versatility and ability to handle various materials and applications, allowing you to expand your capabilities in the future.

- Research the factors to consider when buying a CNC router machine.

- Ask yourself important questions before making a purchase.

- Consider the type of CNC router that suits your needs.

- Evaluate the size and capacity of the machine.

- Ensure accessibility and durability of the CNC router.

Understanding CNC Router Machines

CNC router machines are computer-controlled automatic cutting routers designed for a variety of applications. These machines excel in cutting, engraving, drilling, milling, and tapping operations, making them highly versatile in the manufacturing industry.

One of the key advantages of CNC router machines is their ability to work with lighter materials, making them suitable for a wide range of projects. These machines operate at high precision, delivering accurate and intricate results. Whether you need to cut wood, paper, MDF, foam, plastic, acrylic, PVC, stone, light metals, heavy metals, glass, aluminum composite, or fabric, CNC router machines can handle it all.

The automatic nature of CNC router machines allows for efficient and precise machining. By programming the machine to follow specific cutting paths and tool movements, you can achieve consistent and repeatable results. With their high-speed machining capabilities, CNC router machines can enhance productivity and meet tight deadlines.

Key Features of CNC Router Machines:

- Automatic Cutting: CNC router machines are equipped with cutting tools that can perform various tasks like cutting, engraving, drilling, milling, and tapping without manual intervention.

- Lighter Materials: These machines are specifically designed to work on lighter materials, enabling precise cuts and intricate designs.

- High Precision: CNC router machines offer exceptional precision, ensuring that each cut is accurate and consistent.

- Versatile Materials: From wood to metal and everything in between, CNC router machines can handle a wide range of materials, making them suitable for diverse applications.

“CNC router machines revolutionize the manufacturing industry by providing automated cutting solutions for a variety of materials.”

Whether you’re a small business owner, a hobbyist, or a professional in the manufacturing industry, CNC router machines can offer incredible value. With their versatility, high precision, and automation capabilities, these machines can take your projects to the next level.

Why Do You Need a CNC Router?

Owning a CNC router provides numerous benefits and advantages for businesses and individuals alike.

- Cost Performance: A CNC router offers excellent cost performance by reducing operational, labor, and processing costs. It automates the cutting and carving processes, resulting in increased efficiency and lower production expenses.

- Automation: With CNC routers, you can automate various tasks that would otherwise require manual labor. This automation saves time and effort, allowing operators to focus on other critical aspects of production.

- Reduced Operational Costs: By utilizing CNC routers, businesses can reduce operational costs significantly. These machines are designed to optimize material usage and minimize wastage, ensuring optimal efficiency and cost-effectiveness.

- Customized Cutting Fields: CNC routers offer the flexibility to customize cutting fields according to specific requirements. This allows for precise and accurate cutting, resulting in high-quality products and streamlined workflows.

- High Repeatability: CNC routers excel in providing high repeatability, ensuring consistent and uniform results throughout the production process. This allows for reliable and predictable outcomes, even for complex designs.

- Increased Production Capacity: With the automation and efficiency provided by CNC routers, businesses can significantly increase their production capacity. This leads to faster turnaround times, enabling businesses to meet growing demands and scale their operations.

- Versatile Across Industries: CNC routers have applications across various industries, including woodworking, metal fabrication, signage, prototyping, and more. Their versatility makes them a valuable asset for businesses in diverse sectors.

- Improved Safety Conditions: Using CNC routers can help enhance safety conditions in the workplace. By automating hazardous cutting processes, workers are exposed to fewer risks, reducing the likelihood of accidents and injuries.

Investing in a CNC router can revolutionize your production processes, improve efficiency, and ultimately drive business growth. Whether you’re a professional woodworker, a manufacturing facility, or an artist, the benefits of owning a CNC router are undeniable.

Critical Considerations When Purchasing a CNC Router

When investing in a CNC router, it’s crucial to consider several factors to ensure you make the right choice for your needs. By evaluating the following key aspects, you can make an informed decision:

- Type of CNC Router: Determine the specific type of CNC router that aligns with your project requirements and goals. Options include desktop CNC routers, industrial CNC routers, and multipurpose CNC routers.

- Size and Capacity: Assess the size and capacity of the machine to ensure it fits within your available space and can accommodate your desired project dimensions.

- Accessibility: Consider the accessibility of the CNC router, including its positioning in your workshop and the availability of electrical supply points for seamless operation.

- Duty Cycle: Evaluate the duty cycle of the CNC router, which refers to the recommended operating time and cooling periods. A higher duty cycle indicates a machine capable of handling continuous, demanding workloads.

- Durability: Look for a CNC router that offers exceptional durability and longevity. This ensures your investment will withstand heavy usage and provide reliable performance for years to come.

- Customer Service: Research the manufacturer’s reputation for customer service. A reliable and responsive customer support team is essential for prompt assistance and troubleshooting whenever needed.

Considering these critical factors will guide you toward selecting a CNC router that meets your specific requirements, promotes efficiency, and enhances productivity.

| Type of CNC Router | Size and Capacity | Accessibility | Duty Cycle | Durability | Customer Service |

|---|---|---|---|---|---|

| Variety of options available | Ensure it fits available space and project dimensions | Positioning and electrical supply points | Recommended operating time and cooling periods | Longevity and reliability | Responsive and reliable support |

The Most Important Parts of a CNC Router

When it comes to CNC routers, several key components play a vital role in their performance and functionality. Understanding these core parts is essential for anyone looking to purchase or operate a CNC router machine effectively.

1. Spindle

The spindle is one of the most critical parts of a CNC router as it is responsible for the cutting action. Different types of spindles are available, each with its cooling method and handling capabilities. Choosing the right spindle for your specific needs ensures optimal cutting performance.

2. Motor

The motor can be considered the heart of a CNC router. It dictates the machine’s performance, speed, and accuracy. High-quality, powerful motors are essential for achieving precise and efficient cutting, milling, and carving results.

3. Working Bed

The working bed provides stability and support for the workpiece during the machining process. It determines the machine’s overall durability and lifespan. Sturdy and well-designed working beds ensure consistent and reliable performance.

4. Control System

The control system acts as the brain of the CNC router. It interprets the instructions from the operator or the CNC software and coordinates the movement and operation of the machine. An advanced control system allows for more precise and complex machining tasks.

5. Motion Drives

Motion drives control the movement of the CNC router along the X, Y, and Z axes. They are responsible for positioning the spindle, determining the cutting paths, and executing the programmed instructions accurately. High-quality motion drives ensure smooth and precise movements, resulting in excellent machining outcomes.

Overall, these key components work together to deliver exceptional performance and versatility in CNC router operations. Understanding their roles and functionalities can help users make informed decisions when purchasing or operating a CNC router.

Types of CNC Routers

When it comes to CNC routers, there are various types available to suit different needs and applications. Whether you’re a hobbyist working on small-scale projects or a large-scale manufacturer, there’s a CNC router that can meet your requirements. Let’s explore some of the most common types of CNC routers:

Desktop CNC Routers

Desktop CNC routers are compact machines designed for hobbyists, educational institutions, and small-scale projects. They offer versatility and ease of use, making them ideal for beginners or those with limited workspace. Desktop CNC routers are suitable for cutting and engraving materials like wood, plastic, and soft metals.

Industrial CNC Routers

Industrial CNC routers are heavy-duty machines built for high-volume manufacturing and commercial applications. These robust machines can handle large-scale projects and are capable of cutting, carving, and milling various materials, including wood, metal, and composites. Industrial CNC routers offer increased precision, speed, and efficiency, making them a popular choice in industries like aerospace, automotive, and furniture manufacturing.

Multipurpose CNC Routers

Multipurpose CNC routers are versatile machines that combine multiple capabilities, such as milling, lathe work, and laser engraving. These machines provide enhanced flexibility and can handle complex projects that require different machining techniques. Multipurpose CNC routers are commonly used in prototyping, small-scale production, and artistic applications.

Material-Specific CNC Routers

There are also CNC routers specifically designed for working with specific materials. For example, aluminum CNC routers are equipped with features like high-speed spindles and rigid frames to handle the challenges of cutting aluminum. Wood CNC routers are optimized for woodworking projects, offering precision and smooth cuts in various wood types. Metal CNC routers are specifically built to tackle heavy-duty metal cutting and machining tasks.

Axis Configuration: 3-Axis, 4-Axis, and 5-Axis CNC Routers

CNC routers are classified based on their axis configuration, which determines the machine’s range of motion and the complexity of cuts it can perform.

- 3-Axis CNC Routers: These routers move along the X, Y, and Z-axes, making them suitable for basic cutting, carving, and drilling tasks.

- 4-Axis CNC Routers: In addition to the X, Y, and Z-axes, these routers also feature a rotary axis, allowing for the creation of intricate 3D designs and cylindrical cuts.

- 5-Axis CNC Routers: These advanced machines have the capability to move along all five axes, including the X, Y, Z, as well as rotate on two additional axes. This unparalleled flexibility enables the creation of complex shapes and multi-sided cuts with precision.

Light-Duty CNC Routers

Light-duty CNC routers are designed for occasional or low-volume use. They are smaller in size and have lower power compared to their industrial counterparts. Light-duty CNC routers are suitable for woodworking enthusiasts, crafters, and small businesses with light machining needs.

| Type | Applications |

|---|---|

| Desktop CNC Routers | Small-scale projects, hobbyists, educational institutions |

| Industrial CNC Routers | High-volume manufacturing, commercial applications |

| Multipurpose CNC Routers | Prototyping, small-scale production, artistic applications |

| Material-Specific CNC Routers | Woodworking, metal cutting, aluminum fabrication |

| Axis Configuration | 3-Axis, 4-Axis, 5-Axis CNC Routers |

| Light-Duty CNC Routers | Woodworking enthusiasts, crafters, small businesses |

Popular Desktop CNC Routers to Consider

When it comes to desktop CNC routers, there are two popular options that can meet your needs: the TwoTrees TTC 450 and the Annoytools 3018 Plus. These budget-friendly desktop options offer exceptional performance and versatility.

One standout feature of these CNC routers is their all-aluminum frame construction, ensuring durability and stability during operation. The robust frame provides a reliable foundation for precise cutting and engraving tasks.

Both the TwoTrees TTC 450 and the Annoytools 3018 Plus are equipped with a high-torque motor, allowing for efficient and accurate machining. This powerful motor ensures smooth operation and consistent performance, even when working with tough materials.

Additionally, these desktop CNC routers come with included accessories, making them convenient and user-friendly right out of the box. You won’t have to worry about purchasing additional components separately, as these routers are ready to use with the included accessories.

Whether you’re a hobbyist or a professional, the TwoTrees TTC 450 and the Annoytools 3018 Plus offer reliable performance and versatility at an affordable price. Consider these desktop CNC routers for your next project.

The Software Side: CAD, CAM, and CNC Programs

When it comes to CNC routers, the software side plays a crucial role in the entire machining process. Understanding the various programs involved, such as CAD, CAM, and CNC, is essential for efficient and accurate operation.

CAD (Computer Aided Design) Program

A CAD program is used to create detailed designs and models. It allows users to design intricate shapes, dimensions, and features with precision. These designs are typically exported as 2D drawing files, often in the .dxf format, which can be easily imported into other programs.

CAM (Computer Aided Manufacturing) Program

The CAD file created in the previous step is imported into a CAM program. The CAM program takes the design and generates a toolpath program, which determines the movement and cutting operation of the CNC router. It calculates the optimal toolpath, considering factors such as cutting speeds, depths, and tool changes.

The generated toolpath program, commonly written in G-code, serves as instructions for the CNC router to follow. G-code is a standardized programming language that specifies the precise movements, feeds, and speeds required for the CNC machine to perform the desired operations.

It’s worth noting that post-processors may be needed to optimize the G-code program for specific CNC machines. These post-processors ensure that the G-code generated by the CAM program is compatible with the particular CNC router being used, enabling seamless communication between the software and hardware.

CNC (Computer Numerical Control) Program

The CNC program is the final step in the software side of CNC machining. It interprets the G-code program generated by the CAM software and controls the movements of the CNC router accordingly. The CNC software communicates with the machine’s controller, enabling precise positioning, tool changes, and overall coordination of the machining process.

By utilizing CAD, CAM, and CNC programs, operators can take their designs from concept to reality, creating intricate and precise parts with ease. These software tools enable efficient toolpath generation, accurate machine movements, and ultimately, high-quality finished products.

Understanding the software side of CNC routers is vital for harnessing the full potential of these powerful machines. By leveraging the capabilities of CAD, CAM, and CNC programs, users can unlock a world of design possibilities and achieve optimal results in their machining operations.

Understanding Part Zero, Program Zero, and Work Offset

When working with CNC routers, it’s crucial to have a clear understanding of Part Zero, Program Zero, and Work Offset. These reference points and positioning techniques play a significant role in ensuring the accuracy and precision of your CNC machining process.

Part Zero

Part Zero refers to the origin or reference point on the CAD drawing. It is typically set at X = 0, Y = 0, Z = 0 coordinates. Part Zero serves as a starting point for defining the position and dimensions of the workpiece in the design. By establishing Part Zero, you can align your CAD model with the physical workpiece.

Program Zero

Program Zero is the origin point of the toolpath program or G-code. It is usually aligned with Part Zero. Program Zero acts as a starting point for the tool’s movement and operations. By setting Program Zero correctly, you ensure that the tool follows the desired path and performs the intended cutting, drilling, or milling actions accurately.

Work Offset

Work Offset refers to the specific location on the CNC router table where the workpiece is positioned. Typically, it is in the lower left-hand corner of the table. Work Offset allows you to define the exact position of the workpiece in relation to the CNC router’s reference points. By properly setting the Work Offset, you ensure that the tool interacts with the workpiece in the intended manner and achieves the desired machining results.

It’s important to note that these reference points – Part Zero, Program Zero, and Work Offset – are all interconnected and rely on each other for accurate positioning and machining. They enable the CNC software and machine to translate your design intentions into precise movements and operations.

Understanding and effectively utilizing these reference points and positioning techniques is crucial for achieving optimal results with your CNC router. They form the foundation for accurate and efficient machining processes, providing the necessary coordinates and guidance for the CNC software to execute your design with precision.

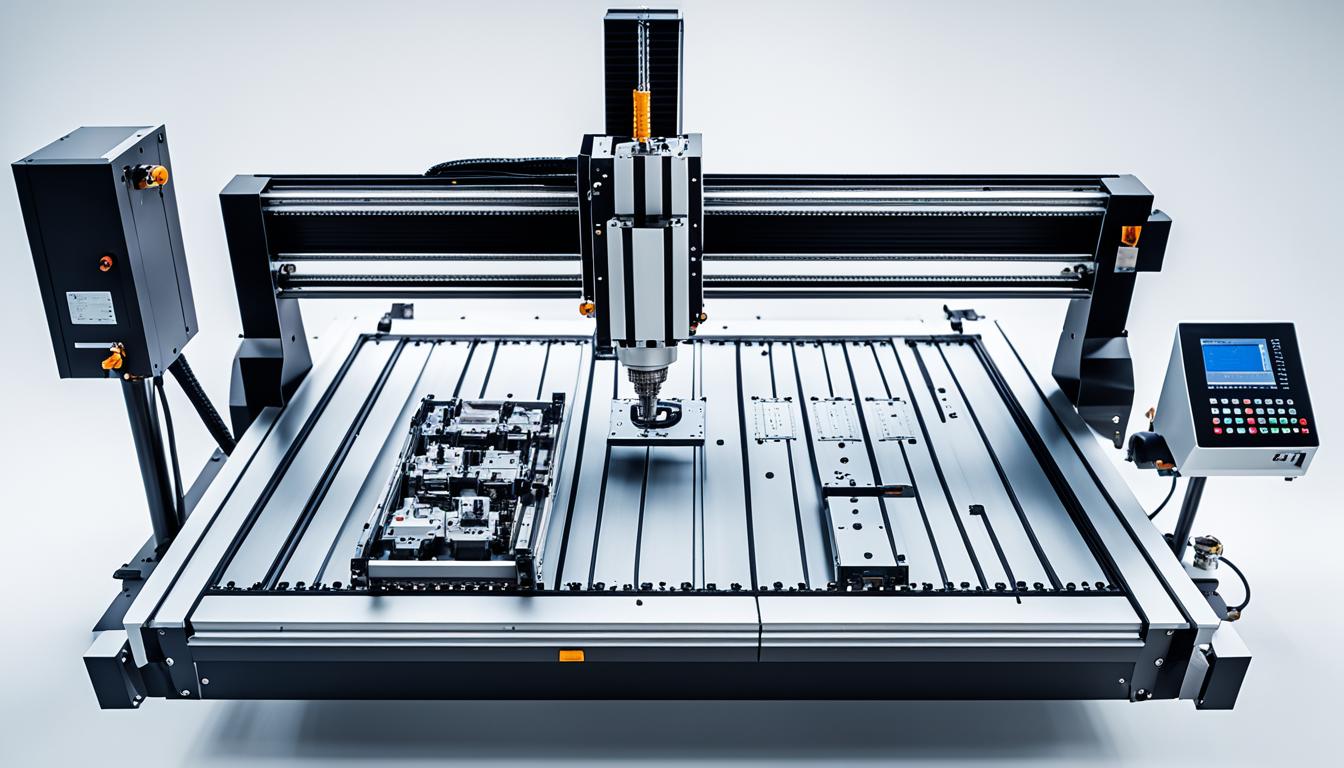

The image above visually represents the concept of Work Offset, showing the positioning of the workpiece on the CNC router table. By aligning the workpiece with the designated Work Offset location, you can ensure accurate and consistent machining results.

Hardware Requirements: Computer, Controller Board, Stepper Motors

To operate a CNC router, you will need several hardware components that are essential for its functioning. These include:

Computer

A computer, preferably a Windows PC, is required to control the CNC router. The computer serves as the central hub for running the necessary software and sending instructions to the machine.

Controller Board

The controller board is a crucial component that interfaces with the computer and controls the operation of the CNC router. It typically consists of motor driver circuits that regulate the movement of the stepper motors.

Stepper Motors

Stepper motors are responsible for the precise and controlled motion of the CNC router. These motors convert electrical pulses from the controller board into rotational movements that drive the machine’s axes.

Power Supply

A reliable power supply is required to provide electrical power to both the computer and the controller board. Make sure to choose a power supply that meets the voltage and current requirements of your CNC router.

USB Cable or Ethernet Cable (For Laptops)

If you plan to connect your CNC router to a laptop, you will need either a USB cable or an Ethernet cable, depending on the compatibility of the controller board. Ensure that the cable is of good quality and has the necessary length to establish a stable connection.

It’s important to note that the computer used for CNC operation should meet the necessary requirements and be dedicated solely to CNC operations. This ensures optimal performance and minimizes the potential for interference from other software or processes running on the computer.

Now that we’ve covered the hardware requirements, let’s explore the software side of CNC routers in the next section.

Safety Considerations and Conclusion

When operating a CNC router machine, ensuring safety should be your top priority. By following proper safety procedures and guidelines, you can prevent accidents and injuries. Familiarize yourself with the machine’s operation and take all necessary safety precautions to create a safe working environment.

CNC router safety begins with proper machine operation. Before starting any task, make sure you understand how to use the machine correctly. Read the manufacturer’s manual and attend training sessions if available. Always wear appropriate safety gear, such as goggles and protective clothing, to protect yourself from flying debris and potential hazards.

In addition to machine operation, there are several safety precautions you should take. Keep the work area clean and organized, removing any unnecessary objects or materials that could cause accidents. Securely fasten workpieces to avoid movement during the cutting process. Regularly inspect the machine for any signs of damage or wear and tear, and promptly address any issues.

In conclusion, prioritizing safety is crucial when operating a CNC router machine. By following safety procedures, properly operating the machine, and taking all necessary precautions, you can ensure a productive and safe experience. Remember, the well-being of yourself and those around you is of utmost importance when working with a CNC router.