The purpose of CNC machining is to automate the production of parts and components with precision and repeatability. It is used to create complex shapes and features that would be difficult or impossible to produce with manual machining. CNC machining is used in a variety of industries, including aerospace, automotive, medical, and consumer products.

What is CNC machining and how does it work?

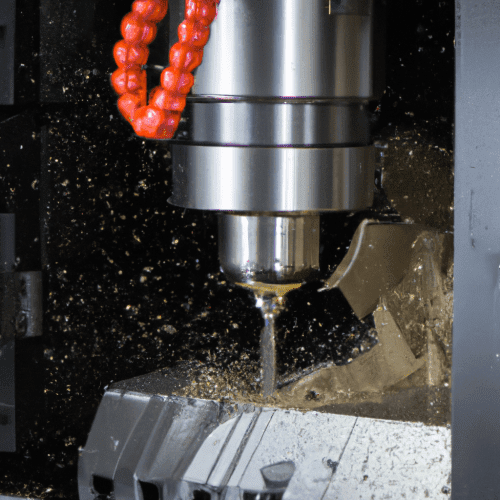

CNC (Computer Numerical Control) machining is a manufacturing process that uses computer-controlled machine tools to shape and cut materials. It works by using a computer program to control the movements of the machine tools, which can be used to cut, drill, grind, or shape a variety of materials. The computer program is programmed with the exact specifications of the desired product, and the machine tools are then used to create the product with precision and accuracy.

What are the advantages of CNC machining?

The advantages of CNC machining include increased accuracy and repeatability, improved productivity, reduced labor costs, increased flexibility, and improved product quality. CNC machining also allows for complex shapes and designs to be created with ease, as well as the ability to produce parts in large quantities with minimal setup time. Additionally, CNC machining can be used to create parts with tight tolerances and intricate details.

What materials can be machined using CNC technology?

CNC technology can be used to machine a wide variety of materials, including metals such as aluminum, steel, brass, and copper; plastics such as acrylic, polycarbonate, and nylon; and wood.

What types of components can be produced using CNC machining?

CNC machining can be used to produce a wide variety of components, including complex shapes and precision parts. Common components produced using CNC machining include engine parts, medical components, aerospace components, and automotive parts. CNC machining can also be used to produce custom parts for a variety of industries, including electronics, robotics, and consumer products.

What are the benefits of CNC machining compared to traditional machining methods?

The main benefits of CNC machining compared to traditional machining methods are increased accuracy, repeatability, and efficiency. CNC machining can produce parts with tighter tolerances and higher precision than traditional machining methods, and can also produce parts faster and with less waste. Additionally, CNC machining can be used to produce complex shapes and geometries that would be difficult or impossible to produce with traditional machining methods.

What types of industries use CNC machining?

CNC machining is used in a variety of industries, including automotive, aerospace, medical, electronics, and consumer products. It is also used in the production of tools, dies, and molds.

What are the safety considerations when using CNC machines?

When using CNC machines, it is important to take safety precautions to ensure the safety of the operator and those around them. This includes wearing appropriate safety gear such as safety glasses, hearing protection, and gloves. Additionally, operators should be aware of the potential hazards associated with the machine, such as flying debris, sharp edges, and moving parts. It is also important to ensure that the machine is properly maintained and that all safety guards are in place and functioning properly.

What are the costs associated with CNC machining?

The cost of CNC machining depends on a variety of factors, including the complexity of the part, the material used, the number of parts being machined, and the time required for machining. Generally, CNC machining costs range from $50 to $100 per hour, depending on the complexity of the part. Additionally, the cost of materials used in CNC machining can vary significantly depending on the type of material used.

What types of software are used to control CNC machines?

The types of software used to control CNC machines are typically Computer Aided Design (CAD) software, Computer Aided Manufacturing (CAM) software, and CNC machine control software. CAD software is used to create the design of the part, CAM software is used to create the toolpaths for the CNC machine to follow, and CNC machine control software is used to control the actual machine.

What types of maintenance are required for CNC machines?

CNC machines require regular maintenance to ensure optimal performance and longevity. This includes lubrication, cleaning, and inspection of parts, as well as checking for any signs of wear or damage. Additionally, it is important to check for any software updates or upgrades that may be necessary.