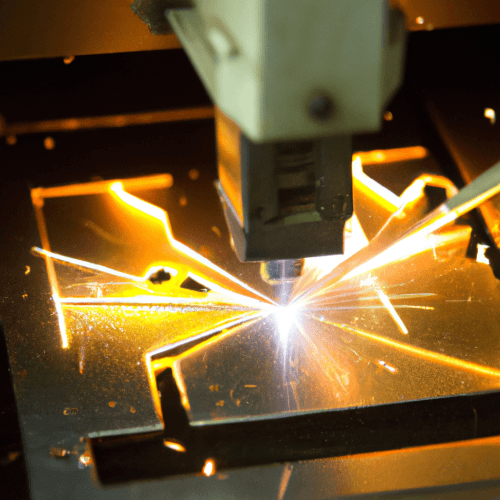

Laser cutting is a process that uses a laser to cut materials, such as metal, wood, plastic, and foam. It is a precise and cost-effective method of cutting a wide variety of materials. Laser cutting is often used in industrial manufacturing applications, but is also becoming popular for hobbyists and small businesses.

The main advantage of laser cutting is its accuracy. Lasers can cut with a high degree of precision, allowing for intricate designs and complex shapes to be cut with ease. Laser cutting also produces a clean, smooth edge with minimal burrs or roughness. This makes it ideal for applications where a high degree of accuracy and precision is required.

Another advantage of laser cutting is its speed. Lasers can cut through materials quickly and efficiently, allowing for large quantities of material to be cut in a short amount of time. This makes it ideal for mass production applications.

Laser cutting is also a cost-effective method of cutting materials. Lasers require minimal setup and maintenance, and the cost of the laser itself is relatively low.

Why do people use laser cutting?

Laser cutting is a process used to cut materials such as metal, wood, plastic, and more. It is a precise and efficient way to cut materials, and is used in a variety of industries, including automotive, aerospace, medical, and electronics. Laser cutting is used because it is a fast and accurate way to cut materials. It is also a cost-effective method, as it requires less energy and fewer tools than traditional cutting methods. Additionally, laser cutting can be used to create intricate designs and shapes that would be difficult to achieve with other methods. Laser cutting is also a safe process, as it does not produce any hazardous fumes or dust. Finally, laser cutting is a versatile process, as it can be used to cut a variety of materials, including metals, plastics, wood, and more.

Why are laser used for cutting metals?

Lasers are used for cutting metals because they offer a number of advantages over traditional cutting methods. Lasers are able to cut metals with a high degree of precision and accuracy, and they can also cut complex shapes with ease. Lasers are also able to cut metals at a much faster rate than traditional cutting methods, and they can also cut thicker materials than traditional methods. Additionally, lasers are able to cut metals without generating heat, which can be beneficial when cutting sensitive materials. Lasers also produce a cleaner cut than traditional methods, which can be beneficial when cutting materials that require a high degree of precision. Finally, lasers are able to cut metals without producing any hazardous waste, which can be beneficial for the environment.

What are the advantages and disadvantages of laser cutting?

Laser cutting is a process that uses a laser beam to cut materials such as metal, wood, plastic, and foam. It is a highly accurate and precise method of cutting, and is often used in industrial manufacturing and prototyping. Laser cutting is a fast and efficient way to produce complex shapes and intricate designs.

Advantages of Laser Cutting

1. High Precision: Laser cutting is a highly precise process that can produce intricate shapes and designs with a high degree of accuracy. The laser beam is focused to a very small spot size, allowing for very precise cutting.

2. Fast Production: Laser cutting is a fast process, allowing for quick production of parts and components. This makes it ideal for high-volume production runs.

3. Versatility: Laser cutting can be used to cut a variety of materials, including metal, wood, plastic, and foam. This makes it a versatile tool for a variety of applications.

4. Automation: Laser cutting can be automated, allowing for faster production and less manual labor.

Is laser cutting environmentally friendly?

Yes, laser cutting is an environmentally friendly process. Laser cutting is a non-contact process that does not require the use of any chemicals or solvents, and it does not produce any hazardous waste. The laser beam used in the process is very precise and efficient, meaning that it only cuts the material that is necessary, reducing the amount of material waste. Additionally, laser cutting does not require any additional energy to be used in order to cut the material, as the laser beam is self-contained and does not require any additional energy sources. This makes laser cutting a very efficient process, as it does not require any additional energy to be used in order to complete the cutting process. Furthermore, laser cutting does not produce any hazardous fumes or particles, making it a safe process for both the environment and the workers. Finally, laser cutting is a very fast process, meaning that it can be completed quickly and efficiently, reducing the amount of time and energy that is used in the process. All of these factors make laser cutting an environmentally friendly process.

What can we do with laser cutting machine?

A laser cutting machine is a powerful tool that can be used for a variety of applications. It is a type of CNC (Computer Numerical Control) machine that uses a laser beam to cut materials such as wood, plastic, metal, and even fabric. The laser beam is directed by a computer program, allowing for precise and intricate cuts.

One of the most common uses of a laser cutting machine is for cutting and engraving. It can be used to cut intricate shapes and patterns into a variety of materials, such as wood, plastic, metal, and fabric. It can also be used to engrave text, logos, and other designs onto the material. This makes it ideal for creating custom signs, labels, and other products.

Another popular use of a laser cutting machine is for creating 3D models. It can be used to cut out intricate shapes and patterns from a variety of materials, such as wood, plastic, metal, and fabric. This makes it ideal for creating custom 3D models for prototyping and product design.

What things can be made in a laser cutter?

A laser cutter is a type of machine that uses a laser beam to cut and engrave materials such as wood, plastic, metal, and fabric. It is a versatile tool that can be used to create a variety of items, from intricate designs to large-scale projects.

One of the most common uses of a laser cutter is to create intricate designs in wood, plastic, and metal. This can include engraving logos, text, or images onto the material. It can also be used to cut out shapes from the material, such as letters, numbers, or other shapes. Laser cutters can also be used to create intricate designs in fabric, such as lace or embroidery.

Another popular use of a laser cutter is to create 3D models. This can include creating models of buildings, vehicles, or other objects. The laser cutter can be used to cut out the pieces of the model and then assemble them together.