Metal milling is a process used to shape and form metal components by removing material from a workpiece. It is a very versatile process that can be used to create a wide variety of shapes and sizes, from simple flat parts to complex 3D shapes. Metal milling is a popular choice for many manufacturing applications due to its ability to produce precise and accurate parts with a high degree of repeatability.

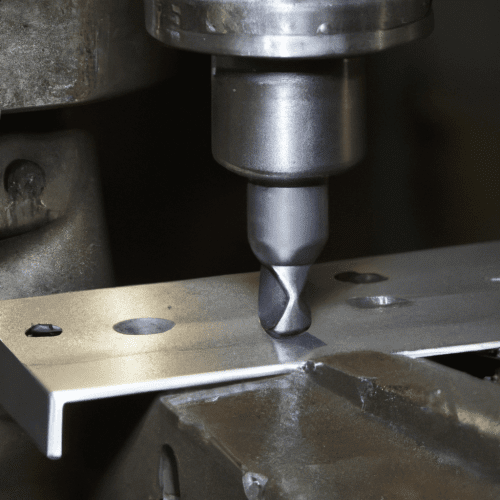

The process of metal milling begins with the selection of the right type of milling machine and the right type of cutting tool. The cutting tool is typically a rotating cutting tool such as an end mill, drill bit, or router bit. The cutting tool is then used to remove material from the workpiece in a controlled manner. The cutting tool is moved in a linear or rotary motion, depending on the type of milling machine being used.

The type of material being milled will determine the type of cutting tool used. For example, softer materials such as aluminum and brass require a softer cutting tool such as a high-speed steel end mill.

What is the purpose of milling process?

Milling is a machining process that uses a rotating cutting tool to remove material from a workpiece. It is a versatile process that can produce a wide range of shapes and sizes, from simple flat surfaces to complex contours and shapes. The purpose of milling is to shape and finish a workpiece by removing material from the surface of the workpiece. It can also be used to create features such as slots, grooves, and pockets. Milling can also be used to create complex shapes and contours, as well as to create intricate patterns and designs. Milling is often used in the manufacturing of parts for automobiles, aircraft, and other machinery. It is also used in the production of medical devices, electronics, and other products. Milling is a precise process that requires the use of specialized tools and machines, as well as a skilled operator. The process is often used in combination with other machining processes, such as turning, drilling, and grinding, to create a finished product.

Why is milling necessary?

Milling is a process that is used to shape and cut materials such as metal, wood, and plastic. It is an important process in manufacturing, as it allows for the creation of complex shapes and parts with a high degree of precision. Milling is necessary because it allows for the production of parts with intricate details and complex geometries that would otherwise be difficult or impossible to produce. Additionally, milling is used to create parts with a high degree of accuracy and repeatability, which is essential for many industrial applications.

Milling is also used to create parts with a high degree of surface finish. This is important for many applications, such as automotive and aerospace components, where a smooth surface finish is necessary for optimal performance. Additionally, milling is used to create parts with a high degree of dimensional accuracy, which is essential for many applications, such as medical implants and precision instruments.

What is the importance of machining in the metal industry?

Machining is an essential process in the metal industry, as it is used to shape and form metal into the desired shape and size. It is used to create components for a variety of applications, from automotive parts to medical implants. Machining is also used to create intricate parts with precise dimensions, which is essential for many industries.

The process of machining involves cutting, drilling, grinding, and other operations to shape and form metal into the desired shape and size. It is a highly precise process, and the accuracy of the finished product depends on the skill of the machinist. Machining is also used to create intricate parts with precise dimensions, which is essential for many industries.

Machining is also used to create components with specific properties, such as hardness, strength, and corrosion resistance. This is important for many industries, as it allows them to create components that are suitable for their specific application.

What is milling process metal?

Milling process metal is a process of removing material from a workpiece by using a rotating cutting tool. It is a form of machining, which is the most common form of material removal in metalworking. The cutting tool is usually a milling cutter, which is a rotary cutting tool with multiple cutting edges. The milling process involves the use of a milling machine, which is a machine tool used to shape and form metal and other materials. The milling machine typically consists of a spindle, which rotates the cutting tool, and a table, which is used to hold the workpiece. The cutting tool is moved in a linear direction across the workpiece, removing material in the form of chips. The milling process can be used to create a variety of shapes and features on the workpiece, including slots, pockets, and contours. It can also be used to create complex shapes and features, such as threads and splines. The milling process is used in a variety of industries, including automotive, aerospace, and medical.

What is milling process in agriculture?

Milling is a process used in agriculture to prepare grains for consumption. It involves grinding the grain into a powder or flour, which can then be used to make bread, pasta, and other food products. The process of milling can be done either by hand or by machine.

When milling by hand, the grain is placed in a mortar and pestle and ground into a powder. This method is often used for small batches of grain, as it is a slow and labor-intensive process.

When milling by machine, the grain is placed in a hopper and fed into a milling machine. The machine grinds the grain into a powder or flour, which is then collected in a container. This method is much faster and more efficient than milling by hand, and is often used for large batches of grain.

Milling is an important process in agriculture, as it allows farmers to turn their grain into food products that can be consumed by humans. It is also used to create animal feed, which is used to feed livestock.

What are the main requirement in the milling process?

Milling is a machining process that involves the use of a rotating cutting tool to remove material from a workpiece. The main requirements of the milling process are that the workpiece must be held securely in place, the cutting tool must be able to move in three directions (X, Y, and Z), and the cutting tool must be able to rotate at a high speed.

The workpiece must be held securely in place so that it does not move during the milling process. This is typically done with a vise, a clamp, or a fixture. The cutting tool must be able to move in three directions (X, Y, and Z) so that it can cut the material in all directions. The cutting tool must also be able to rotate at a high speed so that it can cut the material quickly and efficiently.

What is milling process in pharmaceutical industry?

Milling is a common process used in the pharmaceutical industry to reduce the particle size of active ingredients and excipients. It is a mechanical process that uses a variety of milling tools to break down the material into smaller particles. The milling process can be used to reduce the particle size of both active ingredients and excipients, as well as to improve the homogeneity of the mixture.

The milling process begins with the selection of the appropriate milling tool. The tool is chosen based on the desired particle size and the type of material being milled. Common milling tools include hammer mills, pin mills, ball mills, and jet mills. Once the milling tool is selected, the material is fed into the milling chamber. The milling tool then breaks down the material into smaller particles. The size of the particles is determined by the size of the milling tool and the speed at which it is operated.

What does milling mean in food processing?

Milling in food processing is the process of grinding or crushing different types of food into smaller pieces. This process can be done using a variety of different methods, including grinding, crushing, cutting, and pulverizing. Milling is often used to reduce the size of food particles, making them easier to digest and absorb. It can also be used to create a finer texture in certain foods, such as flour or sugar. Milling can also be used to separate different components of a food, such as separating the bran from the endosperm in wheat. Milling is an important step in food processing, as it can help to improve the nutritional value, texture, and flavor of the food.