The CNC industry in 2024 is characterized by an increased emphasis on sustainable practices and environmentally friendly CNC operations. The paradigm shift towards an eco-conscious and innovative industry is driven by multiple factors, including smart factories, circular economies, on-demand manufacturing, and the integration of collaborative robots. In this article, we will explore the growing trends and advancements in the CNC machining evolution, which cater to both the demand for efficient production and the call for environmental responsibility. Keep reading to discover how sustainability is shaping the future of CNC machining.

The Intersection of Innovation and Sustainability in CNC Machining

CNC machining is at a critical intersection where innovation meets sustainability. Innovations such as the integration of advanced technologies for on-demand manufacturing and the use of eco-friendly materials are becoming increasingly significant. These advancements support the global push for greener solutions amidst heightening environmental consciousness. The interplay between sustainable practices and innovative techniques is seen in the implementation of smart factory concepts, the collaboration of cobots in manufacturing, and the increasing role of digital twin technology. Such advancements are ensuring that the CNC industry remains responsible and forward-thinking, with sustainability as a core objective guiding the evolution of manufacturing practices in 2024.

Key developments in the eco-conscious CNC industry include:

- Smart factories equipped with Industry 4.0 technologies

- Collaborative robots (cobots) working alongside human operators

- Digital twin technology for part and process optimization

These green machining solutions contribute not only to environmental preservation but also help manufacturers achieve higher efficiency and better resource utilization.

| Green Machining Solutions | Benefits |

|---|---|

| Smart factories | Reduced energy consumption, improved operational efficiency, less waste |

| Collaborative robots (cobots) | Increased productivity, industrial safety, and adaptability |

| Digital twin technology | Optimized designs, reduced materials waste, enhanced process predictability |

These sustainable manufacturing techniques help close the loop in the production process, ensuring proper management of the CNC industry’s environmental footprint. In doing so, the industry is creating a sustainable future by integrating forward-thinking innovations with responsible practices that benefit both the environment and manufacturing concerns across the globe.

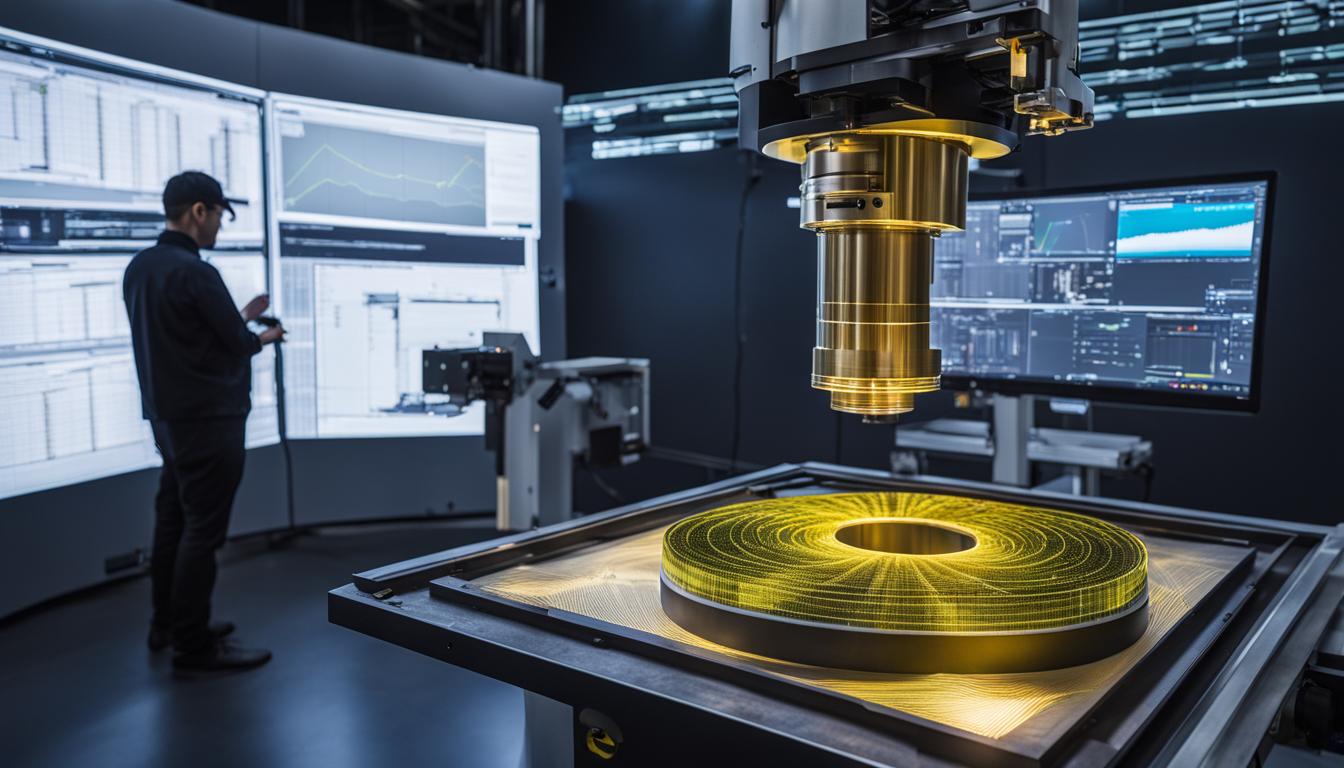

Smart Factories: Revolutionizing CNC Machining with AI and IoT

The advent of the smart factories revolution has transformed the CNC machining landscape by embracing intelligent automation and real-time optimization. By integrating AI, IoT devices, and real-time data analytics, manufacturing systems have evolved into interconnected ecosystems. These ecosystems are designed to enhance the efficiency of production processes, reduce the occurrence of downtime, and optimize operations through real-time insights and data-driven decision-making.

Intelligent Automation and Real-time Optimization in CNC

Intelligent automation in CNC has reached new levels in 2024, ensuring that the manufacturing floor is not only automated but also adaptive and predictive. This new paradigm allows manufacturing systems to respond accurately to the dynamic demands of production without compromising environmental considerations. As a result, smart factories have become a cornerstone in the CNC machining revolution, driving sustainable and efficient practices that align with Industry 4.0 standards.

The Role of AI in Predictive Maintenance and Machine Learning

Artificial Intelligence (AI) is at the forefront of advancing CNC machining through predictive maintenance and machine learning. The AI-enabled systems within smart factories enable the anticipation of equipment maintenance needs, reducing unexpected downtimes and prolonging machine life. This is particularly crucial in today’s fast-paced manufacturing environment, where any loss of productivity can have significant consequences.

- Predictive algorithms that lead to better maintenance scheduling and component replacement

- Automated monitoring of equipment to minimize unexpected downtimes

- Machine learning algorithms that refine CNC operations and optimize cutting parameters

These AI-driven solutions contribute to sustainable practices that benefit the industry in terms of resource conservation and cost reduction. As we move forward, integrating AI and IoT in CNC machining will continue to redefine the manufacturing landscape, paving the way for a greener and more efficient future.

Eco-Friendly Materials and Practices in Modern CNC Operations

Modern CNC operations are increasingly incorporating eco-friendly materials and practices to reduce environmental impact and embrace sustainable development. This includes the use of sustainable and advanced composites, bio-based plastics, and recyclable materials. Advancements in material science allow CNC operations to embrace eco-friendly alternatives that offer improved strength, durability, and heat resistance while maintaining an ecological balance. Alongside material innovations, CNC companies are also focusing on energy-efficient machinery, reduction of waste, and sustainable manufacturing processes that contribute to a greener planet while meeting industrial demands.

Some of the most notable eco-friendly materials in CNC include:

- Biodegradable plastics derived from renewable resources

- Recycled metal alloys and plastics

- Advanced composites made from natural fibers

These materials provide significant environmental benefits without compromising the quality and performance of the end products. Combined with sustainable trends in CNC machining, such as optimized toolpaths, CNC machine shops can further minimize their carbon footprint and enhance their overall sustainability.

Energy-Efficient Machinery and Waste Reduction Strategies

Another critical aspect of sustainable CNC operations is the integration of energy-efficient machinery and waste reduction strategies. Modern CNC machines are designed to consume less energy through intelligent power management systems and the use of energy-saving components such as spindle drives and motors. In addition to adopting these advanced machines, CNC machining companies are implementing various waste reduction techniques, including:

- Optimizing cutting tool geometry and process parameters for efficient material removal

- Utilizing advanced CAD/CAM software to minimize waste during the design and manufacturing phases

- Reusing or recycling scrap materials and cutting fluids

These measures not only minimize resource consumption, but also reduce operating costs and create a circular economy within the CNC machining industry.

| Eco-Friendly Materials | Advantages |

|---|---|

| Biodegradable Plastics | Reduced environmental impact, sourced from renewable resources |

| Recycled Metal Alloys and Plastics | Conservation of energy and resources, reduced waste production |

| Advanced Composites with Natural Fibers | Enhanced mechanical properties, sustainable sourcing, reduced reliance on petroleum-based materials |

Incorporating eco-friendly materials and practices in CNC operations demonstrates the industry’s commitment to adapting and evolving with sustainable trends. By reducing environmental impact, incorporating sustainable materials, and implementing waste reduction strategies, modern CNC operations are ensuring a more responsible and environmentally-sensitive future for the manufacturing industry.

On-Demand Manufacturing: CNC’s Response to Market Dynamics

The CNC industry’s response to modern market dynamics is highlighted by the rise of on-demand manufacturing and a shift to just-in-time production. This approach involves the use of CNC machining to produce custom, made-to-order products that can quickly respond to specific consumer needs or market changes. Just-in-Time manufacturing seeks to eliminate excess inventory, reduce waste, and improve production agility. In 2024, CNC machinists rely on advanced technology such as 3D printing and adaptable CNC setups to cater to these niche market demands, highlighting a significant change in manufacturing philosophies toward more sustainable and responsive operations.

Customized Production and the Shift to Just-in-Time Manufacturing

Customized CNC production has become increasingly important, with consumers expecting personalized products and rapid delivery times. This trend is driving a shift towards just-in-time manufacturing, where products are made on-demand and inventory levels are minimized through efficient production methods. This method has clear benefits for sustainability, as it reduces waste and energy usage by only producing the exact amount of products needed at any given time.

- On-demand manufacturing CNC allows for a more flexible approach to production, adjusting to fluctuating market demands with ease.

- Just-in-time manufacturing CNC focuses on eliminating waste by producing only what is needed, when it is needed.

- Customized CNC production enables the creation of unique, personalized products, meeting consumer demands for individualization.

To further illustrate the benefits of on-demand manufacturing and just-in-time production, let’s look at a comparison of these approaches with traditional mass production methods.

| Manufacturing Approach | Inventory Levels | Waste | Flexibility |

|---|---|---|---|

| Traditional Mass Production | High | High | Low |

| On-Demand Manufacturing | Low | Low | High |

| Just-in-Time Manufacturing | Low | Low | High |

As can be seen from the table above, both on-demand manufacturing and just-in-time production have distinct advantages over traditional mass production methods in terms of lowered inventory levels, reduced waste, and increased flexibility. These practices signify a step towards more sustainable and responsive operations, ensuring that the CNC machining industry can adapt to the modern market’s evolving needs and expectations.

The Symbiosis of Cobots and CNC Machinists

In the pursuit of manufacturability, sustainability, and efficiency, cobots, or collaborative robots, have emerged as valuable assets within CNC machining environments. These robots have gained momentum for their ability to work alongside human operators, delivering significant boosts in productivity and precision throughout the manufacturing process.

From relatively straightforward applications, such as loading and unloading materials, to more intricate assembly procedures, the CNC industry in 2024 has embraced cobots as a vital component of the workflow. The symbiosis between cobots and CNC machinists hinges on the complementary attributes of human creativity and the robotic aptitude for exactitude.

This growing trend toward incorporating cobots mirrors a broader shift within the industry toward automation and smarter manufacturing processes. Ultimately, these technologies contribute to safer, more efficient, and sustainable production methods while helping to meet increasingly demanding industry expectations.

| Tasks | Advantages |

|---|---|

| Load/unload operations | Reduced worker fatigue and error rates, faster turnarounds |

| Assembly processes | Consistency and precision, minimizing material waste |

| Picking and packing | Increased speed, accuracy, and efficiency in packaging |

| Material handling | Improved safety, minimized risk of workplace injuries |

With the incorporation of cobots in manufacturing, CNC machinists are positioned to overcome various challenges. The fusion of human ingenuity and robotic precision helps to streamline processes, reduce waste, minimize errors, and increase overall productivity. The adoption of collaborative robots in CNC machining demonstrates the industry’s commitment to fostering innovation while preserving safety and sustainability in the workplace.

The Cobots-CNC machinists’ collaboration points to an exciting future for the CNC machining domain and is set to become an even more integral aspect of the industry as it continues to evolve.

Digital Twin Technology in CNC Machining

As the CNC industry continues to evolve and prioritize sustainable practices, digital twin technology has emerged at the forefront of these advancements. This innovative approach involves creating a virtual model of a physical CNC machine or system for simulation, analysis, and control, providing numerous benefits for manufacturers aiming to enhance efficiency and reduce environmental impact.

- Improved efficiency: By simulating CNC processes and designs in a digital environment, manufacturers can identify potential areas of improvement and optimize their operations, resulting in higher levels of efficiency and reduced energy consumption.

- Reduced material waste: Digital twin technology enables companies to test and refine products before they undergo physical production, thereby minimizing the material waste associated with physical prototyping.

- Enhanced precision: By enabling detailed analysis and simulation of CNC operations, digital twins help enhance the precision of manufacturing processes, ultimately resulting in fewer errors and less energy wasted on rework and corrections.

Companies such as Siemens, PTC, and Dassault Systèmes are at the forefront of developing and refining digital twin technology, with their software platforms enabling manufacturers to create, simulate, and analyze virtual CNC machining models in unprecedented detail.

As a result of its numerous benefits, the adoption of digital twin technology is increasingly viewed as an essential component of sustainable CNC practices. With a focus on minimizing environmental impact and maximizing production efficiency, the implementation of digital twins in CNC machining is a testament to the industry’s commitment to integrating cutting-edge innovations in pursuit of a more sustainable future.

Injection Molding Industry Trends: Packaging Innovations and Sustainability

As we approach 2024, the injection molding industry is witnessing significant trends in packaging innovations and sustainability. The push towards eco-friendly solutions has led to the adoption of innovative packaging designs, the usage of recycled materials, and the implementation of energy-efficient processes. Injection molding companies are exploring the use of bio-based plastics and advanced composites to meet sustainability goals. The packaging sector, including plastic injection molding, continues to contribute to global sustainability efforts through its ability to reduce plastic waste and provide efficient packaging solutions for a variety of industries.

In light of the surging demand for sustainable packaging solutions, the injection molding industry has experienced significant transformations, including:

- Embracing innovative packaging design concepts to enhance recyclability and reduce plastic waste

- Utilizing bio-based plastics and advanced composites with improved mechanical properties and reduced environmental footprints

- Implementing energy-efficient processes, technologies, and machinery to minimize operational costs and environmental impact

Eco-Friendly Materials in Injection Molding and CNC Machining

Injection molding and CNC machining companies are increasingly incorporating eco-friendly materials to cater to the growing sustainability trend. These materials include:

- Bio-based plastics derived from renewable resources, such as PLA and PHA, providing a more sustainable alternative to traditional petroleum-based plastics

- Recycled plastics, utilizing post-consumer and post-industrial materials to minimize waste and pollution

- Advanced composites, such as carbon fiber reinforced plastics (CFRPs) and glass fiber reinforced plastics (GFRPs), offering improved strength-to-weight ratios and durability while maintaining an ecological balance

Energy-Efficient Process Innovations in Injection Molding

Energy efficiency has become a critical aspect of the injection molding industry, as companies look for ways to reduce their carbon footprints and operational costs. Some notable energy-efficient process innovations in injection molding include:

- Electric injection molding machines that consume less energy compared to hydraulic counterparts and offer improved precision, cleanliness, and lower operating noise

- Process optimization through advanced monitoring systems, automation, and data analytics, allowing for reduced energy consumption and streamlined production

- Utilizing regenerative energy recovery systems, converting excess energy generated during operations back into power, thereby minimizing energy waste

These trends signify the injection molding industry’s dedication to sustainability and innovation, ensuring a bright future for the sector as it addresses global environmental concerns while delivering high-quality, efficient packaging solutions.

Global Market Influencers: The Rise of the Asian CNC Industry

The Asian region, particularly countries like China, India, Japan, and South Korea, has emerged as a major influencer in the global CNC industry. These nations are shaping CNC machining trends with their technological advancements and increasing demand in sectors such as packaging, automotive, and electronics. The injection molding market within Asia-Pacific is expected to see remarkable growth, with a strong focus on sustainability and advanced materials.

Key players in these regions are driving the need for innovative CNC solutions, automation, and eco-friendly materials, setting trends that resonate across the global manufacturing landscape. This growth in the Asian CNC industry is influencing the global CNC machining market by fostering technological innovations and demand for sustainable practices.

Key Players in Asia Shaping CNC Machining Trends

Some of the key players in the Asian CNC industry include:

- Fanuc Corporation (Japan)

- Okuma Corporation (Japan)

- Haas Automation (China)

- DMG Mori (Japan)

- Doosan Machine Tools (South Korea)

- Shenyang Machine Tools (China)

These leading CNC manufacturers are continuously developing advanced technologies, automation solutions, and sustainable practices to stay ahead in an increasingly competitive market. By incorporating Industry 4.0 technologies, these key players are not only meeting the needs of their domestic markets but also setting the stage for a more sustainable and innovative global CNC machining landscape.

| Company | Country | Main Products | Key CNC Advancements |

|---|---|---|---|

| Fanuc Corporation | Japan | CNC Systems, Robots, and Factory Automation | AI-powered CNC systems and IoT integration |

| Okuma Corporation | Japan | CNC Machine Tools, Automation Solutions, and Software | Energy-saving technologies and smart factories |

| Haas Automation | China | Vertical Machining Centers, Turning Centers, and Routers | High-productivity CNC machines and eco-friendly practices |

| DMG Mori | Japan | CNC Lathes, Milling Machines, and 3D Printers | Scalable automation systems and data-driven manufacturing |

| Doosan Machine Tools | South Korea | Turning Centers, Machining Centers, and Automation Solutions | IoT-based machine monitoring and energy-efficient designs |

| Shenyang Machine Tools | China | CNC Machine Tools, Robots, and Automation Systems | Green CNC solutions and digital twin technologies |

As the Asian CNC industry continues to evolve, these key players are shaping the trends in CNC machining through their cutting-edge technologies and innovative approaches to sustainability. This strong focus on the latest advancements and environmentally responsible practices is reshaping the global CNC machining market and driving it towards a greener and more productive future.

The Growing Role of Automation and Robotics in CNC Machining

The expansion of automation and robotics in CNC machining continues to shape the industry’s trajectory towards efficiency and sustainability. Robotic automation, including robotic part removal, automated inspection, and material handling, has become integral to modern CNC operations. The increasing reliance on automation technologies helps improve productivity, minimize human error, and maintain consistent quality standards.

The role of robotics in CNC machining directly aligns with environmental sustainability goals, as these technologies can lead to reduced energy consumption and waste, ultimately lessening the environmental impact of manufacturing processes. The following table highlights some key benefits of incorporating automation and robotics in CNC operations:

| Benefit | Description |

|---|---|

| Increased productivity | Robotics and automation can handle repetitive tasks at a faster pace and for extended periods compared to human operators, boosting production rates. |

| Reduced human error | Robots consistently perform tasks with high precision, reducing the chances of errors and maintaining quality standards across the production. |

| Energy efficiency | Automated systems and robots often consume less energy than traditional manufacturing methods, contributing to overall energy savings and a reduced environmental impact. |

| Waste reduction | Automation and robotics can help optimize material usage and production processes, resulting in less waste and scrap material. |

Several leading CNC machining companies, such as FANUC, ABB, and KUKA, have developed innovative robotic systems specifically designed for use in CNC operations. These systems ensure seamless integration with various aspects of the manufacturing process, enhancing efficiency and supporting environmentally friendly practices.

By adopting Automation in CNC machining and Robotics in CNC operations, the industry is well-positioned to continue evolving in a manner that successfully balances productivity, quality, and environmental responsibility, minimizing the CNC machining and environmental impact.

New Material Horizons: Sustainable and Advanced Composites

As the CNC machining industry continues to evolve and prioritize environmental sustainability, the use of eco-friendly materials has become increasingly important in modern manufacturing practices. Innovative materials such as sustainable composites in CNC and bio-based plastics CNC are altering the material landscape, offering numerous benefits from reduced environmental impact to improved mechanical properties.

Recyclable materials for CNC machining are also gaining traction, providing versatile options for reducing waste and promoting circular economy principles. By implementing these advanced materials, CNC operations are taking a significant step towards a future where functionality and sustainability go hand in hand.

Exploring the Impact of Bio-Based Plastics and Recyclable Materials

Bio-based plastics and recyclable materials are revolutionizing the CNC machining industry with their unique properties and impressive environmental benefits. These materials not only showcase improved mechanical properties such as increased strength and better heat resistance, but also contribute to lesser ecological impact compared to conventional materials.

Below is a summary of some advanced materials used in the CNC industry and their respective advantages:

| Material | Advantages |

|---|---|

| Biodegradable PLA (Polylactic Acid) |

|

| Bio-based polyethylene |

|

| Composite materials (e.g., biocomposites, advanced fiber-reinforced composites) |

|

The impact of bio-based plastics and recyclable materials on the CNC machining industry is undeniably significant, as these materials open new opportunities for the production of more sustainable and environmentally friendly products. The growing adoption of sustainable composites and other advanced materials in CNC operations reflects the industry’s commitment to marrying high-performance production with ecological responsibility.

Tapping into Digitalization for Enhanced CNC Operations

Digitalization plays a crucial role in enhancing CNC operations, contributing to the reduction of environmental impact and improvement of overall manufacturing processes. Industry 4.0’s advanced technologies, such as the Internet of Things (IoT), Artificial Intelligence (AI), and big data analytics, are at the core of this transformation, turning CNC machining into an efficient, precise, and sustainable practice.

Manufacturers are leveraging digital tools to monitor production processes, optimize designs through simulation software, and improve overall manufacturing quality. These digital innovations pave the way for a fully connected and automated manufacturing floor, characterized by improved efficiency, reduced errors, and streamlined operations. As digitalization continues to evolve and integrate with CNC machining, the industry is better equipped to comply with environmental responsibility mandates while upholding high production standards.

Embracing digitalization has led to enhanced CNC operations, which in turn help satisfy industry demands for sustainability and reduced environmental impact. As IoT, AI, and big data analytics remain crucial drivers of innovation in CNC machining, manufacturers can continue to fine-tune their processes, material choices, and overall strategies to create a greener and more efficient manufacturing landscape.