For CNC beginners, mastering 3D modeling in CAD software is crucial for successful machining projects. To simplify the process, focus on these five key tips: Create precise 2D sketches as the foundation for your 3D models, ensuring accurate dimensions and constraints. Utilize feature-based modeling techniques, such as extrusions, revolves, and lofts, to efficiently build complex shapes from simple profiles. Implement parametric design principles by defining relationships between model elements, allowing for easy modifications and design iterations.

Organize your model structure with a clear hierarchy of features and components, facilitating easier edits and assembly management. Lastly, apply appropriate fillets and chamfers to your model to enhance machinability and reduce stress concentrations in the final part. By following these CAD tips, CNC beginners can create more efficient, accurate, and manufacturable 3D models, streamlining the transition from design to production.

- Choose the right CAD software that aligns with your needs and offers user-friendly features for beginners.

- Start with a simple CAM package to understand the basic concepts of CAM software.

- Tinkercad is a free and user-friendly CAD software perfect for CNC beginners.

- Explore more intermediate and advanced CAD software options as your skills progress.

- Understanding CNC programming basics and how to use CAM software to convert CAD designs into CNC code is essential.

Understanding CAM Software for CNC Beginners

CAM software plays a crucial role in CNC machining. It acts as the bridge between your 3D models and the actual CNC machine, transforming your designs into precise instructions that the machine can follow. For CNC beginners, CAM software can be a bit challenging to navigate at first, but with the right approach, it can be simplified.

Starting with a Simple CAM Package

If you’re new to CNC machining, it’s advisable to begin with a simple CAM package. Starting with a user-friendly software will help you grasp the basics and build your confidence. As you gain more experience, you can gradually explore more sophisticated CAM options that offer advanced features and functionalities.

Learning from Instructional Videos and Tutorials

One of the best ways to understand CAM software is by watching instructional videos and tutorials. These resources provide step-by-step guidance on how to use the software efficiently and effectively. By following along with these videos, you’ll learn valuable tips, tricks, and techniques that will enhance your CAM skills.

To find instructional videos and tutorials, you can search online platforms, such as YouTube or dedicated CNC machining websites. Many CAM software providers also offer their own tutorials and support materials on their websites.

Generating Accurate G-Code Programs

One of the primary functions of CAM software is to generate g-code programs. G-code is the language that CNC machines understand, and it contains the instructions for the machine’s movements, tool paths, and machining operations. By mastering CAM software, you’ll be able to generate accurate g-code programs that translate your 3D models into precisely executed CNC machining operations.

With thorough familiarity with CAM software, you can optimize the toolpaths, specify cutting conditions, define feeds and speeds, and generate efficient and precise g-code programs for your CNC machine.

Choosing the Right CAD Software for CNC Beginners

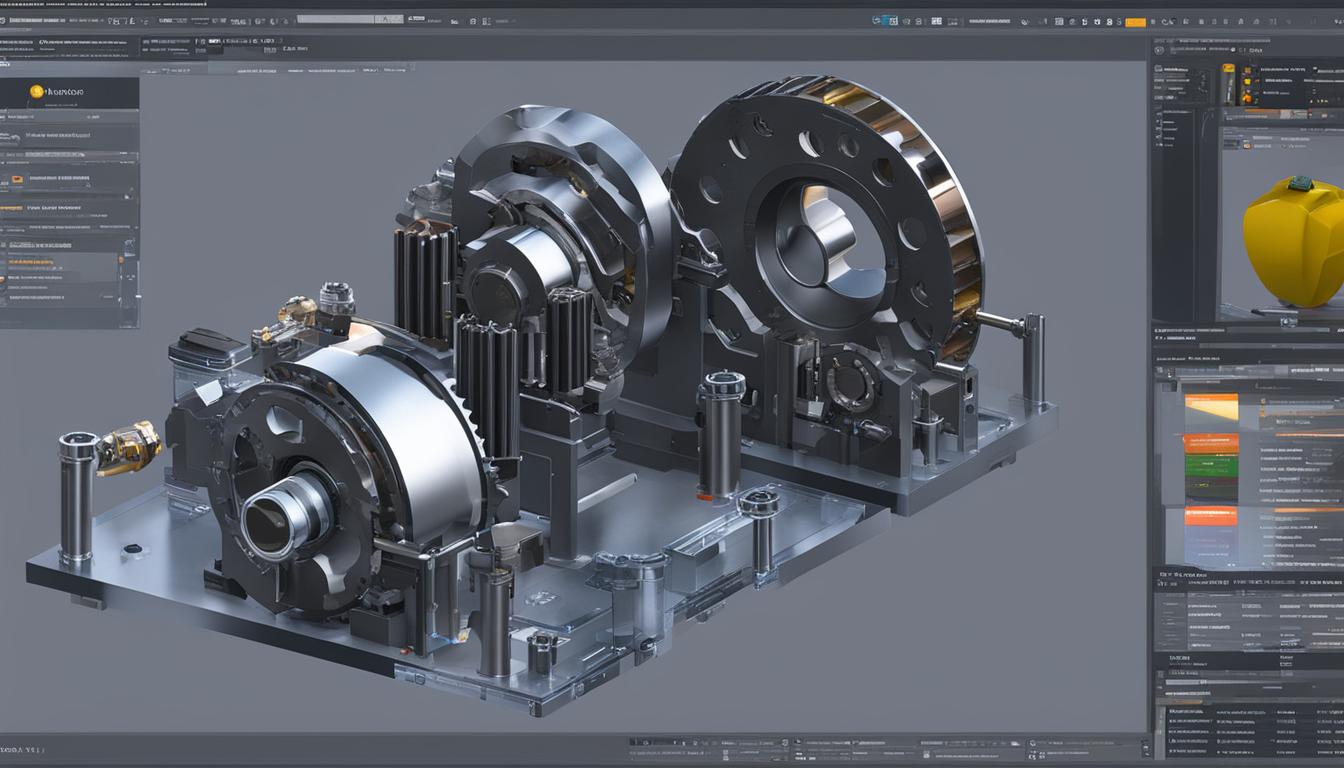

Before diving into CNC machining, it is important to choose the right CAD software. With various CAD programs available, understanding the different types of modeling options is crucial. The two main types of modeling are solid modeling and surface modeling.

Solid Modeling

Solid modeling is a versatile approach that focuses on creating parts that can be produced using CNC machining. It involves creating three-dimensional models with volume and defining their physical properties. Solid modeling is widely used in industries such as manufacturing, engineering, and product design.

Surface Modeling

Surface modeling, on the other hand, prioritizes visual appearance and is commonly used for renderings and animations. It involves creating complex and smooth surfaces, making it suitable for projects that require detailed aesthetics or artistic representation. Surface modeling is commonly used in industries such as automotive design and industrial design.

When choosing the right CAD software for CNC beginners, it is essential to consider your project requirements and long-term goals. Popular CAD software options include:

- Tinkercad

- Autodesk Inventor

- AutoCAD

- Solid Works

- PTC Creo

Each software offers unique features and capabilities, catering to different levels of expertise and project complexity. Consider a CAD software that aligns with your needs and offers user-friendly features for beginners. Now let’s explore these CAD software options in more detail:

| CAD Software | Type of Modeling | Description |

|---|---|---|

| Tinkercad | Both (Solid & Surface) | Tinkercad is a user-friendly CAD software suitable for beginners. It offers both solid and surface modeling capabilities, allowing users to create 3D objects out of geometric shapes. This intuitive software provides tutorials and videos to help beginners learn and gain confidence in their CAD skills. |

| Autodesk Inventor | Solid Modeling | Autodesk Inventor is a powerful CAD software specifically designed for mechanical engineering and product design. It offers robust solid modeling tools, simulation capabilities, and advanced mechanical design features. |

| AutoCAD | Both (Solid & Surface) | AutoCAD is a widely-used CAD software known for its versatility. It offers both solid and surface modeling capabilities, along with a range of additional features for architecture, engineering, and construction industries. |

| Solid Works | Solid Modeling | Solid Works is a comprehensive CAD software popular among engineers and designers. It provides advanced solid modeling capabilities, simulation tools, and extensive collaboration features. |

| PTC Creo | Both (Solid & Surface) | PTC Creo offers a complete suite of CAD software solutions, catering to various industries and design needs. It provides robust solid and surface modeling capabilities, simulation tools, and extensive collaboration features. |

Learning CAD with Tinkercad for CNC Beginners

For CNC beginners looking to dive into the world of 3D modeling, Tinkercad is a fantastic CAD software option. Designed with user-friendliness in mind, Tinkercad allows you to bring your ideas to life by creating 3D objects using basic geometric shapes. It provides an intuitive and enjoyable experience, making it perfect for those who are new to CAD software.

When starting with Tinkercad, it’s best to begin with simple shapes and gradually progress to more complex designs. This approach allows you to familiarize yourself with the software’s features and gain confidence in your CAD skills. Tinkercad also offers a plethora of tutorials and videos to help you on your learning journey.

While Tinkercad may have limitations for more advanced CNC projects, it serves as an excellent stepping stone for CNC beginners. It introduces you to fundamental CAD concepts and equips you with the necessary skills to create basic designs for CNC machining.

Tinkercad’s user-friendly interface and extensive learning resources make it an ideal choice for CNC beginners.

Key Features of Tinkercad

| Feature | Description |

|---|---|

| Geometric Shape Tools | Tinkercad provides a variety of basic geometric shapes, allowing you to create complex designs by combining and modifying these shapes. |

| Alignment and Positioning | You can easily align and position objects within your design using Tinkercad’s intuitive tools. |

| Grouping and Combining | Tinkercad enables you to group multiple objects together and combine them into a single entity. |

| Export Options | You can export your Tinkercad designs in various formats, including STL, OBJ, and SVG, making them compatible with other CAD software and CNC machines. |

| Collaboration | Tinkercad allows you to share your designs with others, making it easy to collaborate on projects. |

With Tinkercad’s user-friendly interface and comprehensive features, CNC beginners can quickly grasp the fundamentals of CAD software and embark on their journey of creating exciting 3D designs.

Exploring Intermediate to Advanced CAD Software for CNC Beginners

As your skills progress in CNC machining, you may find yourself wanting to explore more advanced CAD software options to enhance your projects. Intermediate and advanced CAD software programs offer a wide range of features and capabilities that allow you to take your CNC designs to the next level. While these programs may have a steeper learning curve compared to beginner-friendly options like Tinkercad, they provide greater flexibility and advanced functionalities for CNC beginners.

Intermediate CAD Software

Intermediate CAD software bridges the gap between beginner-friendly programs and complex professional tools. These programs offer a range of features suitable for more intricate CNC projects, allowing you to create detailed 3D models with precision and accuracy. Some popular intermediate CAD software options for CNC beginners include:

- Autodesk Fusion 360

- SolidWorks

- Onshape

These programs offer extensive design and simulation tools, allowing you to visualize and optimize your CNC projects before machining. With intermediate CAD software, you can create complex geometries, incorporate advanced modeling techniques, and explore more sophisticated design elements.

Advanced CAD Software

For CNC beginners looking to push the limits of their creativity and tackle highly complex projects, advanced CAD software is the ideal choice. These programs provide professional-grade tools and functionalities for intricate and demanding CNC designs. Consider the following advanced CAD software options:

- Autodesk Inventor

- AutoCAD

- PTC Creo

These advanced CAD software programs offer advanced modeling capabilities, advanced analysis tools, and extensive libraries of components and materials. They are suitable for CNC beginners who aim to create intricate, high-quality designs that require precise tolerances and sophisticated assemblies.

While intermediate and advanced CAD software may require more time and effort to learn, they offer a significant advantage in terms of the complexity and quality of CNC projects you can undertake. With these tools at your disposal, you can unleash your creativity and take your CNC machining skills to new heights.

Understanding CNC Programming for Beginners

CNC programming is a crucial skill for individuals venturing into CNC machining. It involves the conversion of CAD designs into machine-readable code that dictates the movements and functions of the CNC machine. This code is known as G code, which represents the machine’s geometry and specifies the cutting paths. Additionally, M code handles miscellaneous functions such as tool changes and coolant usage.

While mastering G code and M code programming is not necessary for beginners, having a solid grasp of the basics is essential. It allows beginners to understand the fundamentals of CNC programming and how to leverage CAM software to convert CAD designs into CNC code.

The Role of G Code

G code is the language used by CNC machines to understand and execute the necessary movements and operations. It includes instructions related to linear and circular movements, positioning, feed rate, and spindle speed. By understanding G code, beginners can effectively communicate with the CNC machine and control its actions.

The Importance of M Code

M code, on the other hand, encompasses various auxiliary functions of the CNC machine. It regulates actions like tool changes, coolant usage, machine startup and shutdown, and spindle control. While M code is not always required for every CNC operation, it plays a critical role in ensuring the smooth execution of advanced tasks.

Although learning G code and M code can be intimidating for beginners, modern CAM software simplifies the process. CAM software enables the conversion of CAD designs into CNC code with minimal manual intervention. By utilizing CAM software effectively, beginners can focus on their CAD designs, knowing that the software will handle the intricacies of CNC programming.

| G Code | M Code |

|---|---|

| Specifies cutting paths and movements of the CNC machine | Controls auxiliary functions like tool changes and coolant usage |

| Enables precise positioning and feed rate control | Regulates machine startup, shutdown, and spindle control |

| Dictates spindle speed and tool selection | Facilitates advanced operations and machine functions |

Using CAM Software to Generate CNC Code for Beginners

CAM software simplifies the process of generating CNC code from CAD designs. It takes your CAD models and translates them into machine-specific instructions. By using CAM software correctly, beginners can generate accurate CNC code for their machines, ensuring precise and efficient machining processes.

The Importance of CAM Software in CNC Machining

CAM software plays a crucial role in CNC machining by bridging the gap between CAD models and CNC machines. It allows users to define toolpaths, specify cutting parameters, and generate machine-readable code that controls the movement of the machine tools.

There are various CAM software options available, each offering unique features and capabilities. Some popular CAM software programs include:

- Mastercam

- SolidCAM

- GibbsCAM

- Fusion 360

These programs provide a range of tools and functionalities that facilitate the generation of CNC code, such as:

- Toolpath selection: Choose the most suitable toolpath strategy for your machining requirements.

- Style parameters: Customize cutting parameters and optimize tool movements.

- Cut conditions: Define cutting speeds, feeds, and depths for different machining operations.

- Stock definition: Specify the material shape and size to ensure accurate machining.

Benefits of Using CAM Software for CNC Beginners

For CNC beginners, utilizing CAM software offers several advantages:

- Improved efficiency: CAM software automates the process of generating CNC code, saving time and reducing the risk of manual errors.

- Accuracy and precision: CAM software ensures the translation of CAD designs into precise machine instructions, resulting in accurate and high-quality machined parts.

- Optimized toolpaths: CAM software enables the optimization of tool movements, minimizing cycle times and maximizing the utilization of cutting tools.

- Simulation capabilities: Some CAM software programs provide simulation features that allow beginners to visualize the machining process before sending the code to the CNC machine, reducing the risk of collisions and errors.

By utilizing CAM software effectively, CNC beginners can streamline their workflow and achieve reliable and efficient machining results.

| CAM Software | Main Features |

|---|---|

| Mastercam | Advanced toolpath generation, 3D modeling capabilities, wide range of machining strategies |

| SolidCAM | Integrated with popular CAD software, powerful simulation features, adaptive toolpath strategies |

| GibbsCAM | User-friendly interface, comprehensive tool library, multi-axis machining support |

| Fusion 360 | Cloud-based collaboration, parametric design capabilities, integrated CAD, CAM, and CAE |

Setting Up Your CNC Machine for Beginners

Before starting any CNC machining project, it is crucial to set up your CNC machine correctly. This involves several important steps to ensure the accuracy and safety of the machining process. By following these steps, beginners can execute their CNC projects with confidence.

Cleaning the Machine

Begin by thoroughly cleaning the CNC machine. Remove any debris, dust, or residue from the work area, cutting tools, and spindle. This ensures optimal performance and helps prevent contamination of the workpiece.

Loading and Aligning Cutting Tools

Next, carefully load the appropriate cutting tools into the machine’s tool changer or spindle. Ensure that the tools are securely fastened and aligned according to the manufacturer’s instructions. Proper alignment ensures precision and prevents tool runout during machining.

Warming Up the Machine

It is essential to warm up the CNC machine before beginning any machining operations. This process eliminates thermal expansion, which can affect the accuracy of the machine. Allow the machine to run idle for a few minutes to stabilize its temperature.

Setting Tool Length Offsets

Accurate tool length offsets are crucial for precise machining. Use a tool length measuring device to set the correct length offsets for each tool. This step ensures that the machine knows the exact location of the cutting edges, resulting in accurate machining operations.

Installing the Workpiece Securely

Properly secure the workpiece onto the machine’s workholding device, such as a vice or clamps. Ensure that the workpiece is securely fixed and aligned, and that it won’t shift during machining. This prevents any movement that could negatively impact the accuracy and quality of the finished part.

Calibrating Machine Coordinates

Lastly, calibrate the machine coordinates to ensure accurate positioning of the cutting tools and workpiece. Use a touch probe or edge finder to accurately establish the machine’s reference positions. Calibrating machine coordinates reduces the risk of errors and ensures precise machining.

By following these steps to set up your CNC machine, you can minimize the risk of errors and damage to the machine or workpiece. Proper setup is essential for achieving accurate results and executing CNC projects with confidence.

Monitoring and Troubleshooting CNC Machining for Beginners

When it comes to CNC machining, it is essential for beginners to actively monitor the machine and address any issues that may arise. By staying vigilant and taking proactive measures, you can ensure both your personal safety and the quality of the finished product. Here are some important steps to follow:

1. Visual Inspection

- Regularly inspect the CNC machine for any signs of damage, loose components, or abnormal wear and tear.

- Check for proper installation of cutting tools, workpieces, and fixtures.

2. Listen for Unusual Sounds

- Pay attention to any unusual noises coming from the machine, such as grinding, squealing, or excessive vibrations.

- If you notice any abnormal sounds, investigate further to identify the source and take appropriate action.

3. Monitor Coolant Flow and Temperatures

- Ensure that the coolant system is functioning properly and delivering a sufficient flow of coolant.

- Monitor coolant temperatures to prevent overheating, which can negatively impact both the machine and the workpiece.

4. Be Aware of Smoke or Burning Smells

- If you detect any smoke or burning smells during the machining process, stop the machine immediately.

- Identify the cause of the smoke or smell and rectify the issue before continuing with the machining operation.

5. Conduct Test Runs

- Before machining a workpiece, perform a test run with a similar material to identify any setup or operational problems.

- After completing the machining process, inspect the finished product to ensure it meets the required specifications.

By following these monitoring and troubleshooting practices, beginners can minimize the risk of errors, ensure the safety of both themselves and the machine, and achieve high-quality results in CNC machining.

Importance of High-Quality Tooling for CNC Beginners

When it comes to CNC machining, the quality of tooling cannot be emphasized enough. The tools you use play a crucial role in determining the accuracy, precision, and surface finish of your final product. Investing in high-quality tools not only reduces the risk of tool breakage but also minimizes machine damage and ensures consistent and reliable results.

As a CNC beginner, it’s essential to choose reputable tooling brands that offer durable and precise cutting tools. Quality tools are designed to withstand the rigors of CNC machining, providing optimal performance and longevity. They are manufactured with high-grade materials and cutting-edge technology, ensuring the highest level of precision in your machining projects.

High-quality tooling offers several advantages for CNC beginners:

- Improved Accuracy: Precision is key in CNC machining. Using high-quality tools ensures that your cutting operations are executed with utmost accuracy and repeatability, resulting in finished products that meet the desired specifications.

- Minimized Tool Breakage: Inferior quality tools are more prone to breakage, leading to downtime, increased expenses, and compromised project deadlines. By investing in reliable tooling, you can minimize the risk of tool breakage and maintain a smooth workflow.

- Reduced Machine Damage: The use of low-quality tools can damage your CNC machine, affecting its performance and lifespan. High-quality tools are designed to exert minimal stress on the machine components, ensuring its long-term health and reliability.

- Consistent and Reliable Results: Quality tools deliver consistent cutting performance, ensuring uniformity in your machining projects. The precise cutting edges, balanced geometry, and superior materials of high-quality tooling contribute to the production of reliable and repeatable results.

To make an informed decision when choosing tooling for your CNC projects, consider factors such as the type of materials you’ll be machining, the specific cutting operations required, and the desired surface finish. Additionally, consult with experienced CNC professionals or industry experts who can provide guidance on the best tooling options for your specific needs.

Remember, the quality of your tooling directly impacts the quality of your CNC machining projects. By investing in high-quality tools from reputable brands, you set yourself up for success in achieving accurate, precise, and outstanding results.

The Role of Stable Power Supply in CNC Machining for Beginners

When it comes to CNC machining, one crucial aspect often overlooked is the importance of a stable and consistent power supply. Unlike common single-phase power supply, CNC machines require 3-phase power to operate efficiently. Neglecting this requirement can lead to various issues such as unreliable machine performance, unexpected downtime, and even potential damage to the equipment.

To ensure a stable power supply for precision metalworking, investing in a rotary phase converter is highly recommended. This device converts single-phase power into three-phase power, eliminating the need for expensive electrical infrastructure upgrades. American Rotary phase converters, for example, are known for their reliability and cost-effectiveness in providing a seamless power conversion solution.

A stable power supply plays a vital role in CNC machining for beginners. It reduces the risk of errors during the machining process, enhances the accuracy of the final product, and prolongs the lifespan of the CNC machine itself. By investing in a reliable phase converter and maintaining a consistent power supply, beginners can ensure smooth operation and consistent performance in their CNC machining endeavors.