1. Variable Speed Motor: A variable speed motor is essential for a lathe-mill combo machine and allows for increased precision and accuracy when adjusting the speed of the machine.

2. Digital Readout: A digital readout allows the operator to easily monitor the progress of their work and make precise adjustments to the machine’s settings.

3. High-Torque Spindle Motor: A high-torque spindle motor provides the power needed to tackle large and heavy materials with ease.

4. Adjustable Bed: An adjustable bed allows for the workpiece to be positioned properly with respect to the cutting tool.

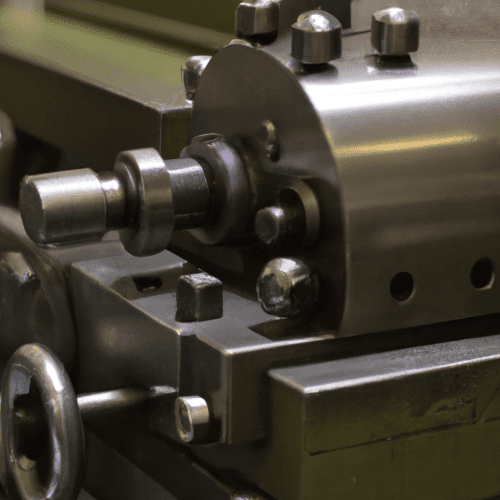

5. Chuck Jaws: Chuck jaws are necessary for securely holding the workpiece in place during machining.

6. Tool Post: A tool post allows for the use of multiple cutting tools on the same workpiece.

7. Safety Features: Safety features such as emergency stop buttons and anti-kickback mechanisms are essential for preventing injury and damage to the machine.

Understanding the Benefits of a Lathe Mill Combo and What Features to Look For

A lathe mill combo is a machine that combines the functions of a lathe and a milling machine into one unit. This type of machine is advantageous as it reduces the amount of space needed in a workshop since it eliminates the need to purchase and maintain two separate machines. It also allows for more flexibility and convenience when working with metal, wood, and other materials. When searching for a lathe mill combo, there are certain features to look for in order to ensure that the machine is suitable for your needs.

Firstly, consider the power of the motor. The more powerful the motor, the more powerful the machine will be, allowing for heavier workloads and more intricate projects.

Secondly, consider the size of the bed. Larger beds allow for larger projects to be completed, while smaller beds are better suited to more intricate projects.

Thirdly, consider the type of material that the machine is designed for. Some lathe mill combos are better suited to cutting metal, while others may be better suited to woodworking.

Next, consider the type of controls available. Many lathe mill combos have digital controls that allow for precise movements and greater accuracy.

Finally, consider the safety features of the machine. Many lathe mill combos come with additional safety features such as dust collection systems and emergency stop buttons to reduce the risk of accidents. In conclusion, a lathe mill combo is an ideal choice for workshops that require a combination of lathe and milling functions. When selecting a lathe mill combo, it is important to consider the power of the motor, size of the bed, type of material it is designed for, type of controls available, and safety features. With the right machine, you can ensure that your projects are completed safely and efficiently.

How a Lathe Mill Combo Can Increase Productivity in Your Shop

Lathe mill combos are becoming increasingly popular in many shops, as they are a great way to increase productivity and save space. These machines are essentially a combination of a lathe and a mill, and they allow users to turn, face, drill, bore, thread, tap, and ream all in one machine. This makes them ideal for producing complex parts and components in a single setup. Lathe mill combos come in a variety of sizes and configurations, and they can be used to perform a variety of operations. Many of these machines feature spindle speeds up to 5,000 revolutions per minute (RPM) and have a wide range of tooling available.

This makes them suitable for a large variety of materials, from soft plastics to hard metals. They also offer a high degree of accuracy and repeatability, which is especially important for applications that require precision. The lathe mill combo is a great choice for shops that require a high level of accuracy and productivity. They are capable of producing complex parts with high precision in a single setup, and they also save time and space. This makes them especially attractive for shops that need to produce intricate parts quickly and accurately. With the right setup and tooling, a lathe mill combo can help increase productivity in any shop.

Exploring the Different Types of Lathe Mill Combos Available on the Market

Lathe mill combos are becoming increasingly popular among both hobbyists and professional machinists alike. These machines combine the capabilities of a lathe and a mill into one unit, allowing you to perform multiple operations without having to switch machines. With so many different types of lathe mill combos available on the market, it can be difficult to know which one is right for your needs. In this article, we will explore the different types of lathe mill combos available and their various features. The most basic type of lathe mill combo is the combination of a lathe and a vertical milling machine. This type of machine is capable of performing both turning and milling operations. It is a great option for people who are looking to do a wide variety of tasks and need the flexibility of both machines. This type of machine is often more affordable than buying two separate machines and may be the right choice if you are new to machining and want to start out with a basic setup.

A more advanced type of lathe mill combo is the combination of a lathe and a horizontal milling machine. This type of machine is ideal for complex projects that require both turning and milling operations. This type of machine is often much more expensive than the combination of a lathe and a vertical milling machine, but it will provide you with a wide range of capabilities. Finally, there is the combination of a lathe and a CNC milling machine. This type of machine is the most advanced type of lathe mill combo available and is designed for complex projects that require precise cutting and machining operations. This type of machine is often more expensive than the other two types, but it will provide you with the most flexibility and precision.

No matter which type of lathe mill combo you choose, it is important to consider your needs before making a purchase. All of these machines have their own pros and cons and you should make sure to do your research before committing to any one machine. Once you have decided which type is best for your needs, you will be ready to begin machining and creating amazing projects.

The Advantages of Investing in a High-Quality Lathe Mill Combo

Investing in a high-quality lathe mill combo can be a great way to ensure that you get the most out of your machining projects. This type of machine offers a range of advantages, including increased efficiency and accuracy in the machining process. Here are some of the main benefits of investing in a high-quality lathe mill combo. First, a lathe mill combo provides a great platform for a wide variety of machining operations. This is because the two machines can be used in combination to create complex parts and components. The benefit of this is that it eliminates the need to buy and maintain separate machines for each operation, thus saving time and money.

Second, a lathe mill combo is highly accurate and precise. The combination of a mill and a lathe allows for greater control over the workpiece, providing for a more consistent and accurate finish. This means that the parts produced are of the highest possible quality. Third, investing in a high-quality lathe mill combo can save you money in the long run. These machines are built to last, meaning they can be used for many years without needing to be replaced. This also means that the cost of ownership is much lower compared to buying individual machines. Finally, a lathe mill combo can provide you with a great way to improve your skills as a machinist. The combination of a mill and a lathe allows you to experiment with different machining techniques, such as drilling, tapping, and threading.

This can help you to become a more experienced machinist, and help you to create more complex and accurate parts. In summary, investing in a high-quality lathe mill combo can be a great way to increase efficiency and accuracy in machining projects. It can also help to save money in the long run and provide an opportunity to improve your machining skills. With all these advantages, investing in a quality lathe mill combo is a great decision for any machinist.

Tips and Tricks for Getting the Most Out of Your Lathe Mill Combo

1. Always read the manual that comes with your lathe mill combo before you start using it. Familiarize yourself with the machine and its components, as well as all the safety instructions.

2. Make sure the lathe mill combo is set up correctly and all components are securely fastened. Make sure the spindle is aligned with the bed and the tailstock is adjusted to the right height. Also ensure the cutting tools are sharp and the table is level.

3. Use the correct cutting speed for the material you are working with. A higher speed will cause too much friction and heat which will damage the tool and the material.

4. Always wear safety gear such as safety glasses, a face shield, and hearing protection when working with the lathe mill combo.

5. Use the correct amount of lubrication to ensure the machine runs smoothly and efficiently.

6. Make sure all the components are securely tightened before starting a job.

7. Always use a clamp to secure the material to the bed. This will provide a stable base for the cutting process.

8. Make sure the material is firmly held in place when cutting. If the material moves, it can lead to an inaccurate cut or damage to the tooling.

9. Take regular breaks to ensure accuracy and consistency when working with the lathe mill combo.

10. Use a light touch when cutting. Too much pressure can cause the tooling to become dull or even break.

Features a Lathe Mill combos must have

Lathe mill combo machines are a great investment for those looking to save space and money in their shop. They combine the features of a lathe and mill in one convenient and efficient machine. Here is a list of the features typically found on lathe mill combos:

- A bed with a hardened and ground guideway for increased accuracy and rigidity.

- A variable speed spindle motor for precision control.

- A digital readout display for precise measurements and adjustments.

- An adjustable tailstock to support the material while turning.

- A motorized tool holder with a variety of tool holders and tooling options.

- An adjustable spindle head for a variety of cutting angles.

- A chuck guard for safety.

- A range of cutting speeds and adjustable depth stops.

- A range of threading options and thread cutting speeds.

- An automatic lubrication system for increased tool life.

- An emergency stop button for safety.

Exploring the Benefits of a Lathe Mill Combination Machine

Lathe mill combination machines are becoming increasingly popular in small workshops and labs. These versatile tools offer the functionality of both a lathe and a mill, allowing operators to perform both turning and milling operations in a single machine. This type of machine can significantly reduce the time required to complete a project, while also providing many other benefits. One of the primary advantages of a lathe mill combination machine is space savings. By utilizing a single machine to perform multiple operations, the amount of floor space needed to complete a job can be greatly reduced. Additionally, many of these machines are designed to be used in a vertical configuration, which further reduces the overall space required.

Another benefit of lathe mill combination machines is their cost efficiency. By purchasing a single machine that can perform multiple operations, the cost of purchasing all the necessary components for a complete setup is significantly reduced. Furthermore, operators are able to get more out of their investment since they are able to produce a variety of parts with a single machine. Lathe mill combination machines also provide operators with greater control over their projects. Since all operations are completed in a single machine, operators can make adjustments and changes to their designs quickly and easily. Additionally, these machines are generally easier to use than separate lathe and mill machines, due to the fact that all operations are contained in a single machine. Finally, lathe mill combination machines offer increased safety. Since operators are only using one machine, they are able to keep their focus on the task at hand, reducing the risk of injury due to distractions. Additionally, many of these machines are equipped with in-built safety features, such as emergency stop buttons, which further reduce the risk of accidents.

In conclusion, lathe mill combination machines offer numerous advantages to operators, including significant space savings, cost efficiency, greater control over projects, and increased safety. This type of machine is an ideal solution for small workshops and labs, as it offers the flexibility to produce a variety of parts quickly and easily.

Understanding the Different Types of Lathe Mill Combos Available

A lathe mill combo is a machine that combines the functions of both a lathe and a mill into one machine. It is a versatile tool, as it can be used for a variety of different tasks. The most common types of lathe mill combos available are benchtop lathe mill combos, floor-standing lathe mill combos, and combination lathe mill drill combos. Benchtop lathe mill combos are the most compact and lightweight of the lathe mill combos available, which makes them ideal for smaller projects and workshops with limited space.

They are also relatively affordable and are a great choice for hobbyists and beginners. However, they are not suitable for larger or more complex projects, as they may not have the power or capacity to handle them. Floor-standing lathe mill combos are the most powerful and robust of the lathe mill combos available. They are designed for heavier-duty projects and are usually more expensive than benchtop models. They also have more features, such as the ability to swivel and tilt the spindle, and provide more control over the cutting process.

Combination lathe mill drill combos are designed to provide the user with both a lathe and a mill, as well as a drill press. These machines are great for larger projects and offer the most versatility, as they can perform multiple tasks in one unit. They are also usually quite expensive and are most suitable for professional use. No matter what type of lathe mill combo you choose, it is important to understand the capabilities and features of the machine before making a purchase. This will ensure that you get the most out of your machine and that it meets your specific needs.

Modern Additions to Lathe Mill Combos to Increase Production Efficiency

1. Digital Readouts: Digital readouts provide accurate and precise measurements to increase the efficiency of the lathe-mill combination. With the ability to measure the exact position of the milling table, these readouts can be used to create more accurate parts without the need for manual calculations.

2. Computer Numerical Control (CNC): CNC technology enables the lathe-mill combination to reach its fullest potential, allowing for automated machining operations with minimal effort. CNC systems can be programmed to create complex designs and shapes, with accuracy and repeatability, while eliminating human errors.

3. Tool Changers: The use of tool changers in a lathe-mill combination allows for faster production by eliminating the need to manually change tools. This increases the cutting speed and reduces the amount of time spent on producing a single part.

4. Automatic Feeds: Automatic feeds provide a cost-effective way to increase production efficiency by reducing the amount of manual labor required. With the ability to feed materials automatically, operators can focus their attention on other tasks.

5. Collet Systems: Collet systems are used to provide a secure connection between the cutting tool and the spindle, enabling the lathe-mill combination to operate at a higher speed and accuracy. This increases the efficiency of the machine, as well as the precision of the parts produced. By incorporating these modern additions to lathe-mill combinations, production efficiency can be greatly improved. The use of digital readouts, computer numerical control, tool changers, automatic feeds, and collet systems can all contribute to the increased productivity of the machine.

What to Look for in a Quality Lathe Mill Combo

When it comes to choosing a quality lathe mill combo, there are several important factors to consider. The first is the construction quality of the lathe mill combo. It should be made with solid, durable materials and should have a solid foundation. The more durable the construction, the better it will be able to withstand heavy duty work. The next factor to consider is the size and capacity of the lathe mill combo. A larger lathe mill combo will be able to handle larger projects and will be more versatile in the types of projects it can handle. A smaller lathe mill combo may be more suitable for smaller projects. The third factor to consider is the features and capabilities of the lathe mill combo.

It should be able to offer a wide range of features such as a variable speed motor, an adjustable cutting tool holder, a digital read-out, and a power feed. The more features the lathe mill combo offers, the better it will be able to handle different types of projects. The fourth factor to consider is the safety features of the lathe mill combo. It should be designed with safety in mind and should have features such as an emergency stop button, an adjustable safety guard, and a shielded motor. These features will help protect the user from potential hazards. Finally, it is important to look for a lathe mill combo that is backed by a good warranty and is from a reputable manufacturer.

This will ensure that the lathe mill combo will last for many years and provide reliable performance. By considering these factors, you can find a quality lathe mill combo that will meet your needs.

Evaluating the Safety Features of Lathe Mill Combos

Lathe mill combos are an excellent choice for machinists and other professionals who need to do a variety of metal and woodworking projects. These machines combine the functions of a lathe, which is used to shape and cut metal and wood, with a mill, which is used to cut and shape metal. While these machines are incredibly versatile and powerful, it is important to consider the safety features when selecting a lathe mill combo. When selecting a lathe mill combo, it is important to consider the safety features, such as the presence of a safety guard. Lathe mill combos should have a guard that covers the spindle and chuck to prevent debris from being thrown out of the machine. Additionally, the guard should be adjustable so that it can be set to the desired height.

This will ensure that the user is not exposed to any dangerous debris. Another important safety feature to consider is the presence of a shield to protect the user from flying debris. The shield should be made of a durable material and should be able to cover the entire working area of the machine. The shield should also be adjustable so that it can be moved out of the way when necessary. In addition to these safety features, a lathe mill combo should also be equipped with an emergency stop button. This button should be clearly labeled and easy to access in case of an emergency. The emergency stop button should be able to stop the machine quickly to prevent any injury. Finally, when selecting a lathe mill combo, it is important to ensure that the machine is properly grounded. This will help to reduce the risk of electric shock.

Additionally, the machine should be inspected regularly to ensure that all components are in good working order. By considering the safety features of a lathe mill combo, users can ensure that they have a safe and reliable machine that is capable of producing quality results. It is important to thoroughly research the safety features of any machine before making a purchase to ensure that it meets all safety standards and regulations.