A drill press is a versatile and powerful tool that can be used to complete a variety of tasks, from drilling holes in wood to metalworking and more. When purchasing a drill press, it is important to consider a few key factors to ensure that you get the best tool for your needs. First, consider the size and type of work you plan to do with the drill press. Different models of drill presses come in a variety of sizes, ranging from benchtop models to large floor models. The size of the drill press you choose should be based on the size and type of work you plan to complete. Additionally, some drill presses are designed specifically for certain types of jobs, such as woodworking or metalworking. Second, consider the power and speed of the drill press. The power of the drill press will determine how quickly and efficiently it can complete a task.

Generally, more powerful drill presses are more expensive, but they can be more efficient at completing tasks. Additionally, the speed of the drill press should also be considered. Drill presses typically have adjustable speeds, so you can select the speed that is most appropriate for the task at hand. Third, consider features such as a quill lock, depth stop, and digital readout. Quill locks make it easier to adjust the depth of a hole, while depth stops can be used to ensure that a hole is drilled to the same depth each time. Digital readouts are also useful for precision drilling, as they allow you to easily measure the depth of a hole. Finally, consider the price of the drill press. Drill presses can range in price from a few hundred dollars to several thousand dollars, depending on the features and quality. It is important to determine your budget and shop around to find the best deal. By considering these factors, you can be sure to choose a drill press that is best suited to your needs and budget. Investing in a quality drill press can greatly improve the efficiency of your projects and save you time in the long run.

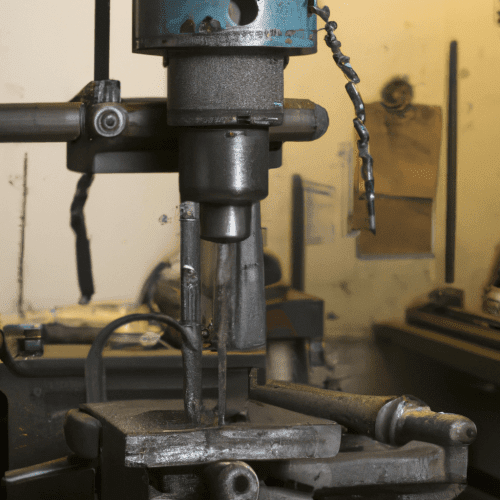

What to Look for When Buying a Drill Press

When selecting a drill press for your home workshop, there are several important factors to consider. First, you must decide whether you need a floor-standing or a bench-top model. Floor-standing drill presses are larger, heavier, and more powerful than bench-top models, and are ideal for larger projects. Bench-top models are more affordable and take up less space, making them suitable for smaller projects. Second, you should consider the size of the quill stroke, which is the distance the quill can travel up and down. The larger the quill stroke, the more versatility the drill press will offer. Third, you should consider the size of the table.

A larger table will provide more space to work with, and will also allow you to work on larger pieces. Fourth, you should consider the speed range. A drill press with a wide range of speeds allows you to work with a variety of materials. Finally, you should consider the number of spindle speeds. The more speeds the drill press has, the more versatility it will offer. By taking these factors into consideration, you can select the drill press that is best suited to your needs.

Understanding Drill Press Accessories and Attachments

A drill press is an essential tool for many shop and home improvement projects. It provides accurate and precise drilling capabilities for a wide variety of materials. To get the most out of your drill press, it is important to understand the various accessories and attachments available. One of the most common drill press accessories is the drill chuck. The drill chuck holds the drill bit securely in place for accurate drilling. It is available in a variety of sizes and styles to fit most drill presses. Another important drill press accessory is the drill bit. There is a large selection of drill bits available for drilling different materials. It is important to select the correct bit for the material being drilled. A drill press vise is also a useful accessory. It securely holds materials in place while drilling. The vise can be adjusted to any angle for precision drilling. For larger projects, a drill press table can be a great addition. The table provides a stable and level surface for drilling.

It also increases the range of materials that can be drilled on the press. Drill press accessories can also include special attachments. These can include sanding drums, countersinks, and forstner bits. These attachments can help to create more complex shapes and designs. Finally, a drill press stand can be a useful addition. It provides a secure and convenient way to mount the drill press. This makes it easier to work with large materials and can provide more stability for precision drilling. By understanding the various drill press accessories and attachments, you can get the most out of your drill press. With the right accessories, you can tackle a wide variety of projects with accuracy and precision.

The Benefits of Owning a Drill Press

A drill press is a valuable tool for any home workshop or professional shop, providing an efficient and accurate method of drilling holes in a variety of materials. Its versatility, precision, and power make it an essential tool for those wishing to complete a wide range of projects. The primary benefit of owning a drill press is its accuracy. Unlike handheld drills, which require a level of skill and experience to ensure proper hole placement, the drill press is designed to make exact and precise holes. This is thanks to its adjustable depth gauge, which allows you to set the exact depth of the hole, as well as its adjustable chucks, which enable you to accurately center the drill bit in the material. With the drill press, you can be sure that each hole will be placed exactly where you need it to be.

Another advantage of the drill press is its power. Unlike a handheld drill, which often struggles to bore through thick or hard materials, the drill press has the power to easily pierce through hardwoods, metals, and plastics. This makes it ideal for a variety of projects, from furniture making to metalworking and more. The drill press also offers greater control over the drilling process. With a handheld drill, you’re limited to drilling in only one direction, whereas the drill press allows you to drill in both directions, allowing for a more precise hole. Additionally, the drill press can be used at variable speeds, giving you greater control over the speed of the drill bit and the rate of material removal. Finally, the drill press is much safer than a handheld drill. With a handheld drill, the user is at risk of slipping or losing control of the drill, which can lead to serious injury. The drill press, however, is designed to remain stable and secure while in use, reducing the risk of accidental injury.

For all of these reasons, owning a drill press can be a great asset for any DIYer or professional. Its accuracy, power, and control make it a tool that can be used for a variety of applications, from woodworking to metalworking and more. If you’re looking for a tool that offers precision and power, the drill press is a great choice.

How to Properly Mount a Drill Press

Properly mounting a drill press can be a challenging task, especially for those who are new to the process. However, with the right tools and knowledge, anyone can successfully mount a drill press in no time. Here are the basic steps to follow when mounting a drill press:

1. Secure the drill press to the floor. Before mounting the drill press, make sure that it is secure on the floor. This can be done by either bolting the drill press to the floor or by placing casters underneath it.

2. Level the drill press. Using a level, make sure that the drill press is completely level. This will ensure that it functions properly and prevent it from vibrating excessively.

3. Secure the table. The drill press table should be securely attached to the drill press. This can be done with a few bolts or screws depending on the model of the drill press.

4. Bolt the stand to the floor. The stand should be securely bolted to the floor. If the stand is not securely bolted to the floor, it can cause the drill press to vibrate excessively.

5. Connect the motor to the power source. Connect the motor to the power source, whether it is a wall outlet or a generator. Make sure that the wattage and voltage are compatible with the drill press. Once these steps have been completed, your drill press should be securely mounted and ready to use. By following these steps, you will be able to properly mount your drill press and ensure that it functions properly for years to come.

Drill Press Maintenance and Safety Tips

Drill presses are an important tool in any workshop. Although they may seem straightforward to operate, there are certain maintenance and safety steps that must be taken in order to ensure that the drill press is working properly and that the user is safe. Maintenance Regular maintenance of your drill press is essential to ensure optimal performance and safety. Always unplug the drill press before performing any maintenance.

1. Clean the drill press frequently to remove any dust and debris.

2. Check all screws, nuts, and bolts to ensure they are tightened to the correct torque.

3. Inspect the drill press table for any damage or warping, as this could cause the drill bit to drift or wobble.

4. Inspect the drill press spindle for any signs of wear or damage. If the spindle is damaged, it should be replaced.

5. Check the power cord for signs of wear and make sure the plug is firmly in place.

6. Check the drill press chuck for any signs of wear or damage. If the chuck is damaged, it should be replaced. Safety Safety should always be the top priority when using a drill press. Be sure to follow these safety tips:

7. Wear safety glasses and appropriate clothing when operating the drill press.

8. Secure the workpiece to the drill press table using clamps or a vise.

9. Make sure the drill press is properly grounded before plugging it in.

10. Set the drill speed to the appropriate rate for the material being drilled.

11. Make sure all guards are in place and functioning properly before operating the drill press.

12. Do not reach across the drill press table while the machine is running.

13. Shut off the drill press and unplug it before making any adjustments. Following these simple maintenance and safety tips will help you get the most out of your drill press and keep you safe while using it.