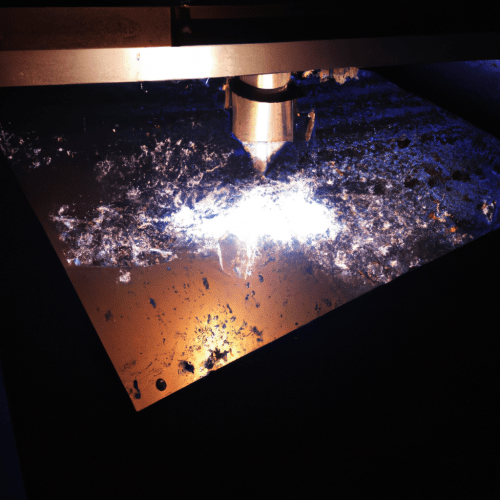

Yes, you can plasma cut aluminum. Plasma cutting is a process that uses a high-velocity stream of ionized gas to cut through electrically conductive materials, such as aluminum. The process works by creating an electrical arc between an electrode and the workpiece. This arc is then used to heat the material to its melting point, allowing it to be cut. Plasma cutting is a fast and efficient way to cut aluminum, and is often used in industrial applications.

The process of plasma cutting aluminum requires the use of a plasma cutter, which is a specialized machine that is designed to cut through electrically conductive materials. The plasma cutter works by creating an electrical arc between an electrode and the workpiece. This arc is then used to heat the material to its melting point, allowing it to be cut. The plasma cutter also uses a high-velocity stream of ionized gas, such as argon or nitrogen, to help cut through the material.

When plasma cutting aluminum, it is important to use the correct settings on the plasma cutter. The settings will depend on the thickness of the aluminum being cut, as well as the type of plasma cutter being used. It is also important to use the correct type of consumables, such as the correct type of nozzle and electrode, to ensure that the cut is clean and precise.

In addition to using the correct settings and consumables, it is also important to use the correct safety equipment when plasma cutting aluminum. This includes safety glasses, gloves, and a face shield. It is also important to ensure that the area is well ventilated, as the process of plasma cutting aluminum can produce hazardous fumes.

Overall, plasma cutting aluminum is a fast and efficient way to cut through electrically conductive materials. However, it is important to use the correct settings, consumables, and safety equipment to ensure that the process is done safely and correctly.

What metals Cannot be cut with plasma cutter?

Plasma cutters are a type of cutting tool that uses a high-velocity stream of ionized gas to cut through electrically conductive materials such as steel, aluminum, brass, and copper. While plasma cutters are capable of cutting through a wide variety of metals, there are some metals that cannot be cut with a plasma cutter. These metals include stainless steel, titanium, and magnesium.

Stainless steel is a type of steel alloy that contains a high percentage of chromium and other elements that make it highly resistant to corrosion. The chromium content of stainless steel makes it difficult to cut with a plasma cutter because the chromium absorbs the heat generated by the plasma arc, making it difficult to cut through the metal.

Titanium is a strong, lightweight metal that is highly resistant to corrosion and heat. It is also highly resistant to the heat generated by a plasma cutter, making it difficult to cut with a plasma cutter.

Magnesium is a lightweight metal that is highly flammable and can easily ignite when exposed to a plasma arc. This makes it dangerous to cut with a plasma cutter, as the sparks generated by the plasma arc can easily ignite the magnesium.

In addition to these metals, there are also some other materials that cannot be cut with a plasma cutter, such as ceramics, glass, and plastics. These materials are not electrically conductive, so they cannot be cut with a plasma cutter.

What gas is used for plasma cutting aluminum?

Plasma cutting aluminum requires the use of a gas such as nitrogen, argon, or a mixture of the two. Nitrogen is the most commonly used gas for plasma cutting aluminum because it is relatively inexpensive and provides a good cutting quality. Argon is also used for plasma cutting aluminum, but it is more expensive and provides a better cutting quality. The mixture of nitrogen and argon is often used when a higher quality cut is desired. The gas used for plasma cutting aluminum is typically delivered to the cutting torch through a gas supply line. The gas is then ignited by an electric arc, which creates a high-temperature plasma jet that is used to cut the aluminum. The gas used for plasma cutting aluminum must be clean and free of contaminants, as any impurities can cause the plasma jet to become unstable and cause poor cutting quality.

Can you CNC plasma aluminum?

Yes, you can CNC plasma aluminum. CNC plasma cutting is a process that uses a high-velocity stream of ionized gas to cut through electrically conductive materials, such as aluminum. The process is similar to traditional oxy-fuel cutting, but instead of using a flame to cut through the material, a plasma torch is used. The plasma torch is composed of a nozzle, an electrode, and a gas supply. The nozzle is used to focus the plasma stream, while the electrode is used to create an electrical arc between the nozzle and the material being cut. The gas supply is used to create the plasma stream.

When cutting aluminum with a CNC plasma cutter, the material is first clamped into place. The plasma torch is then moved over the material in a programmed pattern, using a CNC machine. The plasma stream is then used to cut through the material, creating a precise cut. The cut edges of the aluminum are usually smooth and free of burrs.

CNC plasma cutting is a great way to quickly and accurately cut aluminum. It is also a cost-effective method, as it requires less energy and fewer consumables than traditional oxy-fuel cutting. Additionally, CNC plasma cutting is a safe process, as it does not produce any hazardous fumes or sparks.

Can you plasma cut 6061 aluminum?

Yes, you can plasma cut 6061 aluminum. Plasma cutting is a process that uses a high-velocity stream of ionized gas to cut through electrically conductive materials, such as aluminum. The process works by creating an electrical arc between an electrode and the material being cut, which then melts and vaporizes the material. The plasma arc is then directed through a nozzle, which focuses the arc and increases its velocity. This high-velocity stream of ionized gas is then used to cut through the material.

6061 aluminum is an alloy of aluminum, magnesium, and silicon, and is one of the most commonly used aluminum alloys. It is highly corrosion-resistant and has excellent weldability and machinability. It is also relatively easy to cut with a plasma cutter, making it an ideal material for a variety of applications.

When plasma cutting 6061 aluminum, it is important to use the correct settings on the plasma cutter. The settings will depend on the thickness of the material being cut, as well as the type of plasma cutter being used. Generally, a lower amperage and higher cutting speed should be used for thinner materials, while a higher amperage and lower cutting speed should be used for thicker materials. It is also important to use the correct type of nozzle for the material being cut, as this will help to ensure a clean, precise cut.

Overall, plasma cutting is an effective way to cut 6061 aluminum, and with the right settings and nozzle, it can produce clean, precise cuts.

What is a disadvantage of plasma cutting?

One of the main disadvantages of plasma cutting is that it is not as precise as other cutting methods. Plasma cutting is a thermal cutting process that uses a high-velocity stream of ionized gas to cut through electrically conductive materials. This process is fast and efficient, but it is not as precise as other cutting methods such as laser cutting or waterjet cutting. Plasma cutting can produce a rough edge on the material being cut, which may require additional finishing work to achieve the desired result. Additionally, plasma cutting can produce a lot of heat, which can cause warping or distortion of the material being cut. This can be especially problematic when cutting thin materials, as the heat can cause the material to warp or bend. Finally, plasma cutting can produce a lot of sparks and smoke, which can be hazardous in certain environments.

Can you cut aluminum with a CNC plasma cutter?

Yes, you can cut aluminum with a CNC plasma cutter. CNC plasma cutters are a type of machine that uses a high-velocity stream of ionized gas to cut through metal. The gas is heated to a very high temperature and then directed through a nozzle at the metal, which melts and is then blown away by the gas. This process is known as thermal cutting and is used to cut through a variety of metals, including aluminum.

When cutting aluminum with a CNC plasma cutter, it is important to use the correct settings. The speed and power of the plasma cutter should be adjusted to the thickness of the aluminum being cut. The speed should be set to a lower level for thinner aluminum, and a higher level for thicker aluminum. The power should also be adjusted to the thickness of the aluminum, with a higher power setting for thicker aluminum and a lower power setting for thinner aluminum.

It is also important to use the correct type of nozzle when cutting aluminum with a CNC plasma cutter. The nozzle should be designed specifically for cutting aluminum, as it will be able to withstand the high temperatures and pressures associated with the cutting process. Additionally, the nozzle should be designed to provide a smooth cut, as rough edges can cause the aluminum to warp or crack.

Finally, it is important to use the correct type of cutting gas when cutting aluminum with a CNC plasma cutter. The most common type of gas used is compressed air, but other gases such as nitrogen or argon can also be used. The type of gas used will depend on the thickness of the aluminum being cut, as different gases are better suited for different thicknesses.

In conclusion, aluminum can be cut with a CNC plasma cutter, but it is important to use the correct settings, nozzle, and cutting gas in order to achieve the best results.

What metals can you plasma cut?

Plasma cutting is a process that uses a high-velocity stream of ionized gas to cut through electrically conductive materials, such as metals. It is a very efficient and cost-effective way to cut through metal, and is used in a variety of industries, from automotive to aerospace. The metals that can be plasma cut include aluminum, stainless steel, mild steel, copper, brass, and titanium. Plasma cutting is also used to cut through non-metallic materials such as plastics, composites, and ceramics.

The process of plasma cutting involves the use of a plasma torch, which is a device that produces a high-temperature, high-velocity stream of ionized gas. The gas is then directed through a nozzle, which is used to focus the gas stream and create a precise cut. The plasma torch is connected to a power source, which supplies the energy needed to create the plasma stream. The plasma stream is then directed at the metal, which is heated to a very high temperature and then cut.

The type of metal that is being cut will determine the type of plasma torch that is used. For example, aluminum requires a higher temperature than mild steel, so a higher-powered plasma torch is needed. The type of plasma torch also affects the speed and accuracy of the cut.

The plasma cutting process is very efficient and cost-effective, and is used in a variety of industries. It is also a very safe process, as the plasma stream is contained within the torch and does not come into contact with the operator. Plasma cutting is a great way to quickly and accurately cut through a variety of metals, and is an essential tool for many industries.

What type of metals can the plasma cutter cut?

A plasma cutter is a tool used to cut through electrically conductive materials such as steel, stainless steel, aluminum, brass, copper, and other metals. It works by using an electrical arc to heat the metal to its melting point, and then a high-velocity stream of ionized gas (plasma) is used to blow away the molten metal. Plasma cutters are capable of cutting through a variety of thicknesses of metal, from thin sheet metal to thick steel plates. They are also capable of cutting intricate shapes and patterns, making them a popular choice for metal fabrication and welding projects. Plasma cutters are also used in the automotive, aerospace, and construction industries. In addition to cutting through metal, plasma cutters can also be used to cut through other materials such as wood, plastic, and ceramic.

Can you use a plasma cutter on stainless steel?

Yes, you can use a plasma cutter on stainless steel. Plasma cutters are a type of cutting tool that uses a high-velocity stream of ionized gas to cut through electrically conductive materials, such as stainless steel. The plasma cutter works by creating an electrical arc between an electrode and the material being cut. This arc is then used to heat the material to the point of melting, which allows the plasma cutter to cut through the material. Plasma cutters are often used to cut stainless steel because they are able to cut through the material quickly and accurately. Additionally, plasma cutters are able to cut through stainless steel without leaving any burrs or rough edges, which is important for many applications. However, it is important to note that plasma cutters can be dangerous to use and should only be used by experienced operators. Additionally, it is important to use the correct settings and safety equipment when using a plasma cutter.