Welcome to our in-depth exploration of Desktop Metal, a leading player in the field of metal 3D printing and industrial additive manufacturing. As the demand for metal fabrication and rapid prototyping continues to grow, Desktop Metal’s advanced technology and innovative solutions provide an exciting glimpse into the future of manufacturing.

Desktop Metal was founded in 2015 with a mission to make metal 3D printing accessible for a wide range of applications. Since then, the company has raised an impressive $438 million in venture funding, demonstrating the industry’s confidence in their vision and expertise.

With their cutting-edge 3D printing software and state-of-the-art printers, Desktop Metal offers a range of solutions for metal parts production and manufacturing technology. Their Studio System caters to engineers and small production runs, while their Production System is designed for large-scale printing and manufacturers.

One of the key advantages of Desktop Metal’s technology is its broad material compatibility. They offer various metal powders and materials, including steels, copper, aluminum, and alloys like Inconel, allowing for limitless possibilities in design and fabrication.

Desktop Metal has also garnered attention through strategic collaborations with industry giants such as Ford Motor Company, BMW, and Google. These partnerships not only validate the quality and potential of Desktop Metal’s solutions but also help drive innovation and refine their offerings to meet the specific needs of various sectors.

Recognition and awards have also been showered upon Desktop Metal for their groundbreaking contributions to the manufacturing industry. The World Economic Forum recognized them as a Technology Pioneer, and MIT Technology Review included them among the 50 Smartest Companies in the World.

As we delve deeper into their products, applications, and future outlook, we will uncover the transformative potential of Desktop Metal’s metal 3D printing technology. So, stay tuned as we embark on this exciting journey through the world of additive manufacturing and explore the limitless possibilities it holds for the future of metal fabrication.

History of Desktop Metal

Desktop Metal, a prominent metal 3D printing startup, was founded in 2015 in Cambridge, Massachusetts. The company embarked on a mission to develop a fast and affordable metal 3D printer suitable for office settings. Co-founded by Ric Fulop, Jonah Myerberg, and a team of five others, the company quickly gained attention in the additive manufacturing industry.

Securing approximately $14 million in startup funding, Desktop Metal laid the foundation for its ambitious endeavors. As the company gained traction, it went on to raise additional funds from notable investors such as GE Ventures and Saudi Aramco, propelling its growth and expansion into new markets.

In 2017, Desktop Metal achieved a significant milestone by launching its first two printer systems: the Studio System and the Production System. The Studio System catered to engineers and small-scale production runs, while the Production System was designed to meet the requirements of manufacturers and large-scale printing.

Recognizing the importance of collaboration, Desktop Metal forged strategic partnerships with industry giants like Ford Motor Company and BMW. These partnerships allowed them to refine their technology and tailor it to meet the demanding requirements of the manufacturing sector.

In essence, the history of Desktop Metal is characterized by continuous innovation, pioneering the field of metal 3D printing, and establishing strategic partnerships to drive technological advancements in additive manufacturing.

| Year | Key Milestones |

|---|---|

| 2015 | Desktop Metal founded by Ric Fulop and Jonah Myerberg |

| 2017 | Launch of Studio System and Production System |

| 2017 | Formed partnerships with Ford Motor Company and BMW |

| 2020 | Initiated IPO merger with Trine Acquisition Corp. |

Products Offered by Desktop Metal

Desktop Metal offers a range of 3D printing systems tailored to different applications and needs. Whether you’re an engineer, a manufacturer, or part of a metal job shop, Desktop Metal has a printer system that can cater to your requirements.

Studio System

The Studio System, designed for engineers and small production runs, combines office-friendly hardware with a user-friendly software workflow. This system enables you to create metal parts with ease and efficiency, making it ideal for rapid prototyping and low-volume production.

Production System

The Production System is built for manufacturers and large-scale printing. With advanced capabilities, such as single-pass jetting technology, this system allows you to produce metal parts quickly and cost-effectively on an industrial scale. It is a game-changer for industries that require high-volume metal part production.

Shop System

Desktop Metal has introduced the Shop System, a metal binder jetting printing system specifically designed for machine and metal job shops. This system provides a reliable, affordable, and easy-to-use solution for shops looking to venture into metal 3D printing. With the ability to print complex parts in a variety of metals, the Shop System opens up new possibilities for metal fabrication.

Fiber

When it comes to continuous carbon fiber parts, Desktop Metal has you covered with their Fiber printer. This printer offers high-strength, lightweight, and precise carbon fiber composite parts. With the Fiber printer, you can achieve superior performance and durability in your printed parts, making it suitable for aerospace, automotive, and other demanding industries.

Desktop Metal also provides a wide range of metal powders and materials that are compatible with their printers. Whether you need steels, copper, aluminum, or alloys like Inconel, they have the materials to support your printing needs.

With their diverse portfolio of printing systems and materials, Desktop Metal empowers professionals in various industries to harness the full potential of metal 3D printing and unlock endless possibilities for innovation and manufacturing excellence.

Strategic Partnerships and Collaborations

Desktop Metal has established strategic partnerships with leading companies in the manufacturing and technology sectors. These partnerships enable them to expand their reach, enhance their product offerings, and drive innovation within the industry. Let’s take a closer look at some of their notable collaborations:

Ford Motor Company and BMW

Desktop Metal has forged partnerships with automotive giants Ford Motor Company and BMW. Through these collaborations, they aim to explore innovative manufacturing applications and eliminate the need for warehousing parts. By leveraging Desktop Metal’s advanced metal 3D printing technology, Ford and BMW can streamline their production processes, reduce costs, and achieve greater manufacturing efficiency.

Stratasys

In addition to their partnerships, Desktop Metal has also established a strategic connection with 3D printing pioneer, Stratasys. As an investor in Desktop Metal, Stratasys recognizes the potential of their technology and the value it brings to the industry. This collaboration fosters knowledge sharing, technological advancements, and further propels the growth of both companies.

EnvisionTEC

Furthermore, Desktop Metal has made a significant move in the photopolymer printing space through their acquisition of EnvisionTEC, a leading German company specializing in this technology. This collaboration broadens Desktop Metal’s product portfolio, allowing them to offer a wider range of solutions to meet the diverse needs of their customers.

Through these strategic partnerships and collaborations, Desktop Metal continues to strengthen its position as a key player in the manufacturing and technology sectors. By joining forces with industry leaders like Ford Motor Company, BMW, Stratasys, and EnvisionTEC, they are not only expanding their capabilities but also driving the advancement of additive manufacturing as a whole.

Recognition and Awards

Desktop Metal’s innovative technology and contributions to the manufacturing industry have garnered recognition and numerous awards. The company has been honored by prestigious organizations and publications, solidifying its reputation as a leader in the field.

World Economic Forum Technology Pioneer

Desktop Metal was named a Technology Pioneer by the World Economic Forum in 2017, a prestigious accolade given to innovative companies that have the potential to significantly impact their respective industries. This recognition highlights Desktop Metal’s groundbreaking advancements in metal 3D printing technology and their commitment to driving industrial transformation.

MIT Technology Review Smartest Companies

MIT Technology Review, a leading publication in the technology sector, has included Desktop Metal in its list of 50 Smartest Companies in the World. This acknowledgment reflects the company’s strategic vision, technological expertise, and ability to disrupt and shape the future of additive manufacturing.

Industry Awards

In addition to these esteemed recognitions, Desktop Metal has won various industry awards for their outstanding contributions to the manufacturing and 3D printing landscape. Notable accolades include the Edison Award, which honors innovations that push the boundaries of creativity and ingenuity, and an emerging tech award from Digital Trends, highlighting Desktop Metal’s excellence in the ever-evolving technology industry.

Company Growth and Funding

Since its founding, Desktop Metal has experienced significant growth and secured substantial funding, positioning themselves as a leading player in the metal 3D printing industry. The company has successfully raised a total of $437 million in venture funding, showcasing strong investor confidence in their innovative technology and business model.

Notable funding rounds were led by esteemed investors such as GV (formerly Google Ventures) and Ford Motor Company, further validating Desktop Metal’s potential and market attractiveness. These strategic partnerships have not only provided the company with the necessary capital to fuel their expansion but have also opened doors to valuable industry collaborations and opportunities.

One of the most significant milestones in Desktop Metal’s growth trajectory was their initial public offering (IPO) through a reverse merger with Trine Acquisition Corp. In December 2020, the company began trading on the New York Stock Exchange, marking a major achievement in their journey as a publicly traded company.

The IPO merger enhanced Desktop Metal’s financial position and elevated their corporate profile, capturing the attention of the investment community and industry experts. Their successful IPO merger reflected the market’s confidence in their business strategy, technology, and vision for the future of metal 3D printing.

With a valuation of $1.5 billion, Desktop Metal emerged as one of the fastest-growing “unicorns” in the United States. This achievement not only highlights the company’s rapid growth and market potential but also solidifies their position as a leader in the additive manufacturing space.

Overall, the combination of significant venture funding, successful investment rounds, and the milestone IPO merger has positioned Desktop Metal for continued success and sets the stage for further industry advancements and market dominance.

| Year | Investment Round | Amount Raised |

|---|---|---|

| 2015 | Seed Round | $14 million |

| 2017 | Series A | $115 million |

| 2017 | Series B | $115 million |

| 2019 | Series D | $160 million |

| 2020 | Series E1 | $575 million |

Expansion into Healthcare

Desktop Metal has recently expanded its horizons into the healthcare sector with the launch of Desktop Health. This new venture is dedicated to developing innovative healthcare products that cater to a wide range of fields, including dentistry, orthodontics, dermatology, orthopedics, cardiology, plastic surgery, and printed regenerative applications.

With Desktop Health’s cutting-edge technology and expertise in 3D printing, the company aims to revolutionize the healthcare industry by providing advanced solutions for medical professionals, researchers, and patients alike.

Under the leadership of CEO Michael Mazen Jafar, Desktop Health is committed to creating healthcare products that enhance patient care, improve treatment outcomes, and unlock new possibilities in medical innovation.

By leveraging the power of Desktop Metal’s technological advancements, Desktop Health is poised to make a lasting impact on healthcare by introducing the benefits of 3D printing to the field.

Desktop Health is revolutionizing healthcare with its innovative range of healthcare products.

Acquisition Plans and Deal with Stratasys

In May 2023, industrial 3D printer company Stratasys made an announcement that they intended to acquire Desktop Metal in an all-stock transaction. This acquisition was expected to result in a combined company valuation of $1.8 billion. As part of the deal, existing shareholders of Desktop Metal would own approximately 41% of the merged company.

However, in September, Stratasys terminated the acquisition after the deal was voted against by its shareholders. The termination of the acquisition marked a significant change in the plans for both Desktop Metal and Stratasys.

This unexpected turn of events resulted in the continuation of Desktop Metal as an independent entity, allowing them to pursue their own growth strategies and objectives.

This decision had implications for both companies and their respective shareholders, as it impacted the potential synergies and opportunities that would have arisen from the merger. Nevertheless, both companies remain influential players in the 3D printing industry, with their own unique strengths and capabilities.

Key Features of Desktop Metal’s Technology

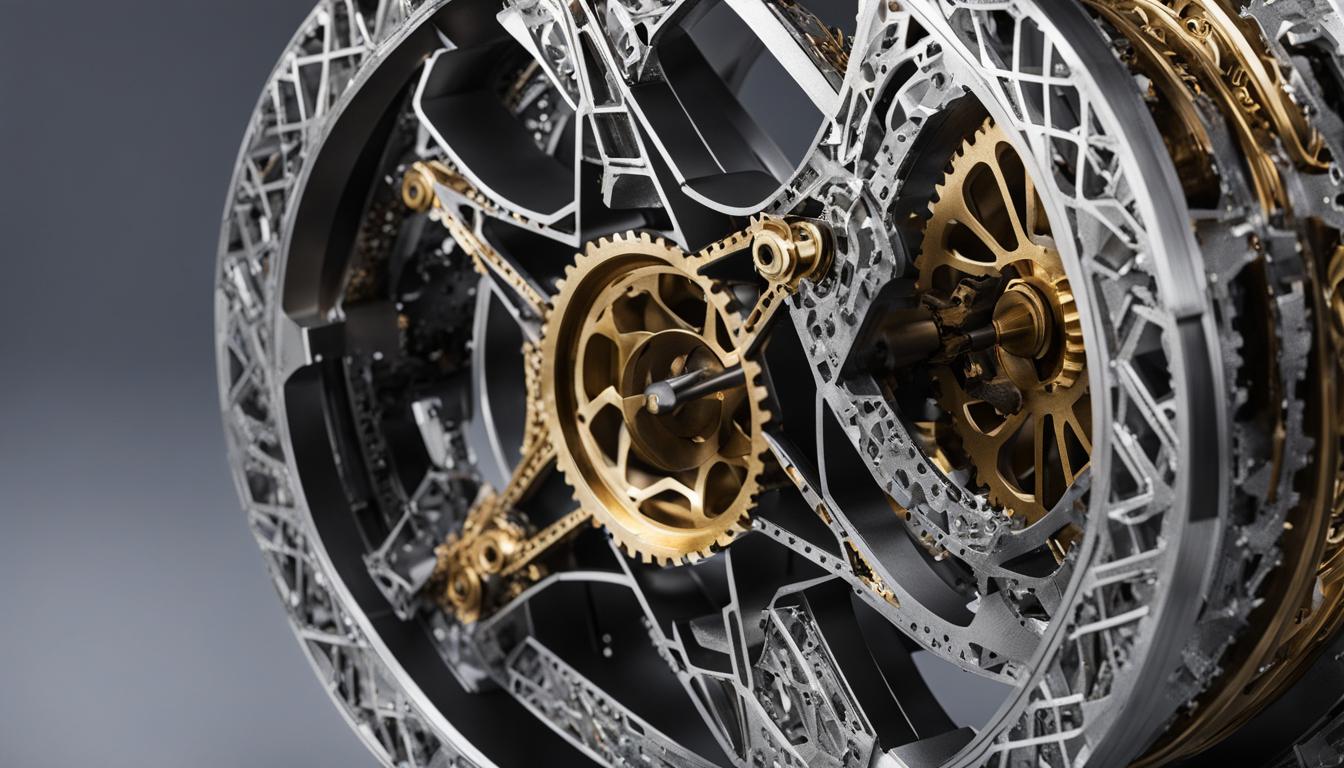

Desktop Metal employs a unique technology known as Bound Metal Deposition to revolutionize the world of metal 3D printing. This process combines the benefits of metal powder and polymer extrusion, enabling the creation of intricate shapes and structures with exceptional accuracy and precision.

With Bound Metal Deposition, Desktop Metal’s 3D printers extrude a carefully formulated mixture of metal powder and polymers, layer by layer, to build objects from the ground up. This method not only ensures precise control over the printing process but also allows for the incorporation of complex geometries that were previously challenging to achieve through traditional manufacturing techniques.

Once the object is printed, it undergoes a crucial step in the production process—the sintering furnace. In the sintering furnace, the printed object is subjected to controlled heat treatment. The polymers in the printed part burn away, leaving behind a porous structure composed of metal particles. The metal particles are then compacted together just below their melting point, resulting in a fully dense and robust final product.

One of the key advantages of Desktop Metal’s technology is its broad material compatibility. The company offers a wide range of metal powders that can be used with their printers, including popular metals such as stainless steel, titanium, and aluminum, as well as various alloys like Inconel. This versatility allows for the production of parts with different material properties, catering to the diverse needs of industries such as automotive, aerospace, medical, and consumer goods.

By harnessing the power of Bound Metal Deposition and its unique combination of metal powder and polymer extrusion, Desktop Metal provides manufacturers with a game-changing solution for metal 3D printing, enabling them to create complex, customized, and high-quality metal parts with ease.

Applications of Desktop Metal’s 3D Printing Solutions

Desktop Metal’s cutting-edge 3D printing technology offers a multitude of applications in various industries. From metal parts production to rapid prototyping and enhancing manufacturing efficiency, their solutions are transforming how businesses operate and innovate.

Revolutionizing Metal Parts Production

With Desktop Metal’s 3D printing solutions, the process of metal parts production has reached new heights. By leveraging advanced additive manufacturing techniques, businesses can now create complex and intricate metal components with exceptional precision and durability. This eliminates the limitations of traditional manufacturing methods and enables the production of custom-designed metal parts that meet specific requirements.

Accelerating Rapid Prototyping

Rapid prototyping is a crucial stage in product development, allowing businesses to iterate quickly and efficiently. Desktop Metal’s 3D printing solutions enable rapid prototyping with metal materials, facilitating the creation of functional prototypes that closely resemble the final product. This significantly reduces the time and cost associated with traditional prototyping methods, allowing businesses to bring their ideas to market faster.

Enhancing Manufacturing Efficiency

Desktop Metal’s 3D printing technology streamlines the manufacturing process by eliminating the need for complex tooling and reducing material waste. By directly printing metal components, businesses can optimize their production workflows, minimize lead times, and enhance overall efficiency. This not only increases productivity but also enables on-demand manufacturing, reducing inventory costs and enabling a more sustainable approach to production.

Unleashing Customizable Designs

One of the remarkable advantages of Desktop Metal’s 3D printing solutions is the ability to create highly customizable designs. Whether it’s intricate geometries, lightweight structures, or personalized components, their technology empowers businesses to push the boundaries of design freedom. This opens up exciting possibilities in industries such as automotive, aerospace, healthcare, and consumer goods, where unique and tailored products are in high demand.

Visual Representation:

| Industry | Application |

|---|---|

| Automotive | Customized automotive components |

| Aerospace | Lightweight and complex aerospace parts |

| Healthcare | Precision medical implants and prosthetics |

| Consumer Goods | Unique and personalized consumer products |

With Desktop Metal’s 3D printing solutions, businesses can embrace the future of manufacturing. By leveraging the power of metal additive manufacturing, they can achieve greater innovation, efficiency, and customization, positioning themselves at the forefront of their respective industries.

Future Outlook for Desktop Metal

With a commitment to continued innovation and a track record of disrupting the market, Desktop Metal is poised for a promising future. As the demand for metal 3D printing technology continues to grow and industries seek more efficient manufacturing solutions, Desktop Metal is well-positioned to meet these needs.

The company’s dedication to research and development ensures that they will remain at the forefront of industry advancements. Desktop Metal’s team of engineers and scientists are continually pushing the boundaries of what is possible in metal fabrication, exploring new materials, and enhancing printing processes.

As Desktop Metal expands its product offerings and continues to refine its technology, they are not only catering to existing markets but also creating new ones. With their innovative 3D printing solutions, Desktop Metal is enabling manufacturers to produce complex and customizable designs, leading to increased efficiency and cost savings.

In the coming years, Desktop Metal’s impact on additive manufacturing and metal fabrication is expected to be significant. As they pave the way for continued innovation, market growth, and industry advancements, Desktop Metal will play a key role in shaping the future of manufacturing technology.