CNC machining is generally considered to be very accurate. Depending on the type of CNC machine and the materials being machined, accuracy can range from 0.001 inches to 0.0001 inches. The accuracy of CNC machining is also affected by the skill of the operator, the quality of the tools being used, and the quality of the programming. In general, CNC machining is considered to be very accurate and reliable.

How precise is CNC machining compared to other machining methods?

CNC machining is highly precise compared to other machining methods. It is capable of producing parts with tight tolerances and high accuracy. CNC machining is able to produce parts with a tolerance of up to 0.001 inches, which is much more precise than other machining methods such as manual machining or EDM. CNC machining also has the ability to produce parts with complex geometries and intricate details that would be difficult or impossible to achieve with other machining methods. Additionally, CNC machining is able to produce parts with a high degree of repeatability, meaning that the same part can be produced multiple times with the same exact specifications.

What factors affect the accuracy of CNC machining?

- Tool Path: The tool path is the path that the cutting tool follows when machining a part. If the tool path is not programmed correctly, the part may not be machined accurately.

- Tool Wear: As the cutting tool is used, it will wear down over time. This can affect the accuracy of the machining process, as the tool may not be able to cut as precisely as it did when it was new.

- Machine Setup: The machine must be set up correctly in order to achieve accurate results. This includes setting the correct spindle speed, feed rate, and tool offsets.

- Workpiece Material: The material of the workpiece can affect the accuracy of the machining process. Harder materials are more difficult to machine accurately, while softer materials are easier to machine.

- Cutting Parameters: The cutting parameters, such as the feed rate, spindle speed, and depth of cut, must be set correctly in order to achieve accurate results.

- Tool Geometry: The geometry of the cutting tool must be correct in order to achieve accurate results. If the tool is not sharp or is not the correct shape, it may not be able to cut accurately.

- Workpiece Fixturing: The workpiece must be securely held in place in order to achieve accurate results. If the workpiece is not held securely, it may move during the machining process, resulting in inaccurate results.

How can CNC machining accuracy be improved?

- Ensure that the CNC machine is properly calibrated and maintained. Regularly check the machine for any wear and tear, and replace any worn parts.

- Use high-quality cutting tools that are designed for the specific material being machined.

- Use a cutting fluid to reduce friction and heat buildup during the machining process.

- Use a high-precision spindle and tooling system to ensure accuracy.

- Use a high-precision CNC controller with advanced features such as look-ahead and adaptive control.

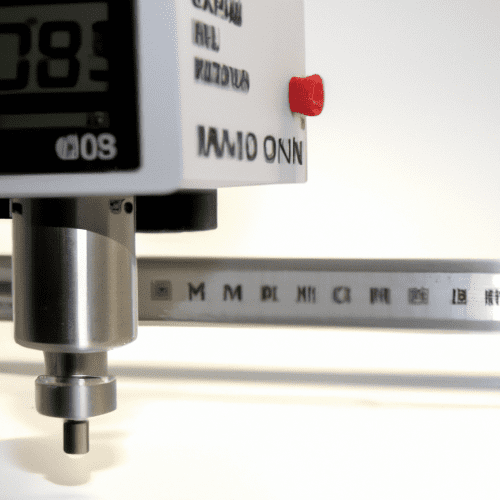

- Use a high-precision CNC machine with a rigid frame and high-precision linear guides.

- Use a high-precision CNC machine with a high-resolution encoder for precise positioning.

- Use a high-precision CNC machine with a high-speed servo motor for faster cutting.

- Use a high-precision CNC machine with a high-resolution digital readout for precise measurements.

- Use a high-precision CNC machine with a high-speed spindle for faster cutting.

What are the most common sources of inaccuracy in CNC machining?

The most common sources of inaccuracy in CNC machining are:

- Tool Wear: As the cutting tool wears, it can cause the cutting path to deviate from the programmed path, resulting in inaccurate parts.

- Tool Deflection: As the cutting tool is subjected to high forces, it can deflect, resulting in inaccurate parts.

- Machine Calibration: If the machine is not properly calibrated, it can cause inaccurate parts.

- Program Errors: If the program is not written correctly, it can cause inaccurate parts.

- Poor Workholding: If the workpiece is not held securely, it can cause inaccurate parts.

- Poor Fixturing: If the fixture is not designed correctly, it can cause inaccurate parts.

- Poor Tool Selection: If the wrong tool is used, it can cause inaccurate parts.

- Poor Tool Paths: If the tool path is not designed correctly, it can cause inaccurate parts.

- Poor Material Selection: If the wrong material is used, it can cause inaccurate parts.

- Poor Coolant Selection: If the wrong coolant is used, it can cause inaccurate parts.

What are the benefits of CNC machining accuracy?

CNC machining accuracy offers a variety of benefits, including:

- Increased Productivity: CNC machining accuracy allows for faster production times, as the machines can produce parts with greater precision and accuracy than manual machining. This means that more parts can be produced in a shorter amount of time, resulting in increased productivity.

- Improved Quality: CNC machining accuracy also ensures that parts are produced with greater precision and accuracy than manual machining. This means that parts produced with CNC machining are of higher quality and are more likely to meet the desired specifications.

- Cost Savings: CNC machining accuracy also helps to reduce costs associated with production. By producing parts with greater accuracy and precision, fewer parts need to be scrapped or reworked, resulting in cost savings.

- Reduced Waste: CNC machining accuracy also helps to reduce waste associated with production. By producing parts with greater accuracy and precision, fewer materials are wasted, resulting in cost savings.

- Increased Safety: CNC machining accuracy also helps to reduce the risk of injury associated with manual machining. By producing parts with greater accuracy and precision, fewer mistakes are made, resulting in a safer working environment.

How does CNC machining accuracy compare to manual machining accuracy?

CNC machining is typically more accurate than manual machining because the machines are programmed with precise instructions and can be adjusted to produce parts with very tight tolerances. CNC machines are also able to produce parts with complex geometries that would be difficult or impossible to produce with manual machining. CNC machining is also faster than manual machining, allowing for higher production rates and shorter lead times. CNC machining is also more consistent than manual machining, as the machines are programmed to produce parts with the same dimensions and tolerances each time.

What are the limitations of CNC machining accuracy?

The accuracy of CNC machining is limited by several factors, including the accuracy of the machine itself, the accuracy of the cutting tools, the accuracy of the programming, and the accuracy of the operator.

- Machine Accuracy: The accuracy of the CNC machine is limited by the precision of the components used in its construction. The accuracy of the machine is also affected by the wear and tear of the components over time.

- Cutting Tool Accuracy: The accuracy of the cutting tools used in CNC machining is limited by the quality of the tools and the sharpness of the cutting edges. The accuracy of the cutting tools is also affected by the speed and feed rate of the cutting tool.

- Programming Accuracy: The accuracy of the CNC programming is limited by the accuracy of the instructions given to the machine. The accuracy of the programming is also affected by the complexity of the program and the skill of the programmer.

- Operator Accuracy: The accuracy of the operator is limited by the skill and experience of the operator. The accuracy of the operator is also affected by the quality of the instructions given to the operator and the quality of the tools used by the operator.

How does CNC machining accuracy affect the quality of the finished product?

CNC machining accuracy is a critical factor in the quality of the finished product. The accuracy of the CNC machining process determines the precision of the finished product, which can affect the overall quality of the product. If the CNC machining process is not accurate, the finished product may have defects such as incorrect dimensions, surface finish, or other imperfections.

Accurate CNC machining ensures that the finished product meets the desired specifications and tolerances. It also ensures that the product is free from defects and has a consistent quality. Accurate CNC machining also reduces the amount of time and money spent on post-processing and finishing, which can further improve the quality of the finished product.

In addition, accurate CNC machining can help reduce the amount of scrap and waste generated during the manufacturing process. This can help reduce costs and improve the overall efficiency of the production process.

Overall, CNC machining accuracy is essential for producing high-quality products. Accurate CNC machining ensures that the finished product meets the desired specifications and tolerances, and reduces the amount of time and money spent on post-processing and finishing. It also helps reduce the amount of scrap and waste generated during the manufacturing process, which can further improve the quality of the finished product.

What types of materials are best suited for CNC machining accuracy?

The type of material best suited for CNC machining accuracy depends on the application and the desired outcome. Generally, materials that are harder and more rigid are better suited for CNC machining accuracy. Metals such as aluminum, steel, and titanium are ideal for CNC machining accuracy due to their strength and rigidity. Plastics such as ABS, polycarbonate, and nylon are also suitable for CNC machining accuracy, although they may require additional support or reinforcement to maintain accuracy. Additionally, some composite materials such as carbon fiber and fiberglass can be machined with CNC accuracy, although they may require specialized tools and techniques.