A CNC (Computer Numerical Control) machine is a type of automated machine tool that uses computer programs to control the movement of the machine’s tools. CNC machines are typically constructed from a combination of metal and plastic components, and are designed to be highly precise and accurate.

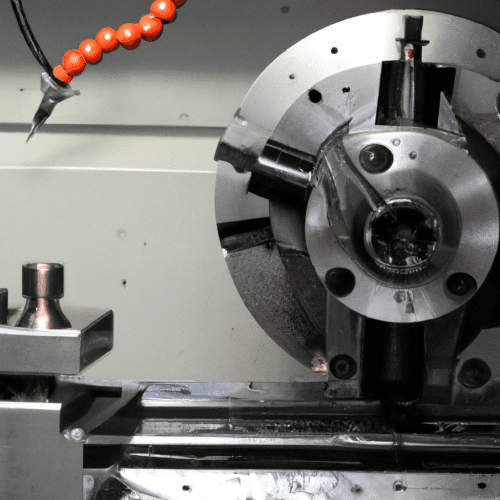

The basic components of a CNC machine include the frame, the spindle, the drive system, the control system, and the cutting tools. The frame is the main structural component of the machine, and is typically made from a combination of metal and plastic components. The spindle is the rotating component of the machine, and is typically driven by a motor. The drive system is responsible for controlling the movement of the spindle, and is typically powered by a motor or a servo motor. The control system is responsible for controlling the movement of the machine’s tools, and is typically powered by a computer program. Finally, the cutting tools are the components that actually cut the material, and are typically made from high-grade steel.

In addition to these basic components, CNC machines may also include additional components such as a coolant system, a dust collection system, and a lubrication system. The coolant system is responsible for cooling the cutting tools, and is typically powered by a pump. The dust collection system is responsible for collecting the dust and debris created by the cutting process, and is typically powered by a vacuum. The lubrication system is responsible for lubricating the cutting tools, and is typically powered by a pump.

Once all of the components of the CNC machine have been assembled, the machine is typically tested to ensure that it is functioning properly. Once the machine has been tested and is functioning properly, it is ready to be used for its intended purpose.

How CNC machines are made?

Computer Numerical Control (CNC) machines are automated machines that are used to cut and shape materials such as metal, wood, and plastic. They are used in a variety of industries, including aerospace, automotive, and medical. CNC machines are made by combining a variety of components, including motors, controllers, and software.

The first step in making a CNC machine is to create the frame. This is typically made from aluminum or steel and is designed to hold the other components of the machine. The frame is then fitted with the motors, controllers, and other components. The motors are typically stepper motors, which are designed to move in precise increments. The controllers are used to control the motors and other components of the machine.

The next step is to install the software. This software is used to control the machine and to create the instructions for the machine to follow. The software is typically written in a programming language such as C++ or Java. Once the software is installed, the machine is ready to be tested.

How CNC machine works step by step?

A CNC (Computer Numerical Control) machine is a type of automated machine tool that uses computer programs to control the movement of the machine’s tools. CNC machines are used to create parts and components for a variety of industries, including aerospace, automotive, medical, and consumer products.

The first step in the operation of a CNC machine is to create a program that will control the machine’s movements. This program is typically created using a CAD (Computer Aided Design) program, which allows the user to create a 3D model of the part or component that needs to be created. Once the 3D model is created, the user can then create a program that will control the machine’s movements. This program is typically written in a language such as G-code or M-code.

Once the program is written, it is then loaded into the CNC machine’s memory. The machine then reads the program and begins to move its tools according to the instructions in the program.

What is CNC machine structure?

A CNC (Computer Numerical Control) machine is a type of automated machine tool that uses computer programs to control the movement and operation of the machine. It is a type of machine tool that uses computer programs to control the movement and operation of the machine. The CNC machine structure consists of three main components: the controller, the drive system, and the machine tool.

The controller is the main component of the CNC machine structure. It is the computer that runs the CNC program and controls the machine’s movements. The controller is responsible for interpreting the CNC program and sending the appropriate commands to the drive system. The controller can be either a dedicated CNC controller or a general-purpose computer.

The drive system is the second component of the CNC machine structure. It is responsible for converting the commands from the controller into motion. The drive system consists of motors, gears, and other components that are used to move the machine tool.

What is CNC machine made of?

A CNC (Computer Numerical Control) machine is a type of automated machine tool that uses computer programs to control the movement and operation of the machine. CNC machines are typically made up of several components, including a controller, a motor, a spindle, a drive system, and a tooling system. The controller is the brain of the machine, and it is responsible for interpreting the instructions from the computer program and sending the appropriate signals to the motor, spindle, and drive system. The motor is responsible for providing the power to move the machine, while the spindle is responsible for rotating the cutting tool. The drive system is responsible for translating the signals from the controller into motion, and the tooling system is responsible for holding and positioning the cutting tool. CNC machines are typically made from a combination of metal and plastic components, and they are designed to be highly precise and accurate.

Where are CNC machines made?

CNC machines are made in a variety of locations around the world. Many of the major manufacturers of CNC machines are based in the United States, Japan, Germany, and Taiwan. In the United States, CNC machines are made by companies such as Haas Automation, Mazak Corporation, and Fadal Machining Centers. In Japan, CNC machines are made by companies such as Fanuc, Okuma, and Yamazaki Mazak. In Germany, CNC machines are made by companies such as DMG Mori, Trumpf, and Heller. In Taiwan, CNC machines are made by companies such as Hiwin, Kinetic, and Leadwell.

In addition to these major manufacturers, there are also many smaller companies that make CNC machines in various countries around the world. These companies often specialize in specific types of CNC machines, such as 3D printers, laser cutters, and milling machines.

How are machines made?

Machines are made through a process called manufacturing. Manufacturing is the process of taking raw materials and transforming them into a finished product. This process typically involves a combination of processes such as cutting, shaping, assembling, and finishing. The first step in the manufacturing process is to create a design for the machine. This design will include the size, shape, and function of the machine. Once the design is complete, the materials needed to create the machine are gathered. This could include metal, plastic, wood, or other materials. The materials are then cut, shaped, and assembled into the desired form. This could involve welding, machining, or other processes. Once the machine is assembled, it is tested to ensure that it meets the design specifications. If any adjustments need to be made, they are done at this stage. Finally, the machine is finished with paint, polish, or other treatments to give it a professional look. Once the machine is complete, it is ready to be used.

How are machine parts made?

Machine parts are typically made through a process called machining. Machining is a manufacturing process in which parts are cut from a block of material, such as metal, plastic, or wood, using a variety of tools such as saws, drills, and lathes. The process begins with a block of material, which is then cut into the desired shape using a variety of tools. The tools used depend on the type of material being cut and the desired shape of the part. For example, a drill may be used to create a hole in a metal block, while a saw may be used to cut a plastic block into a specific shape.

Once the part has been cut to the desired shape, it is then smoothed and polished using a variety of tools such as grinders, sanders, and polishers. This process is used to ensure that the part is free of any imperfections and has a smooth finish.

What is the working principle of CNC machine?

The working principle of a CNC (Computer Numerical Control) machine is based on the use of computer software to control the movement of the machine’s tools. CNC machines are programmed with a set of instructions that tell the machine what to do and how to do it. The instructions are written in a computer language called G-code, which is a language specifically designed for CNC machines. The G-code instructions are sent to the CNC machine’s controller, which is a computer that interprets the instructions and controls the machine’s movements.

The CNC machine is equipped with a number of motors that are used to move the machine’s tools. These motors are controlled by the controller, which sends signals to the motors to move the tools in the desired direction. The controller also monitors the position of the tools and adjusts the speed and direction of the motors accordingly. This allows the CNC machine to accurately and precisely move the tools in the desired direction.

Do CNC machines require any programming?

Yes, CNC machines do require programming. CNC stands for Computer Numerical Control, and the programming is what allows the machine to perform its automated functions. CNC programming is a language that is used to communicate instructions to the machine, telling it what to do and how to do it. The programming language is usually a combination of G-code and M-code, which are the two most common types of CNC programming. G-code is the language used to control the motion of the machine, while M-code is used to control the machine’s functions, such as spindle speed, coolant, and tool selection.

CNC programming is a complex process that requires a good understanding of the machine’s capabilities and limitations. It also requires a good understanding of the programming language and the ability to write code that is both efficient and accurate. CNC programming can be done manually, using a text editor, or it can be done using a computer-aided design (CAD) program.