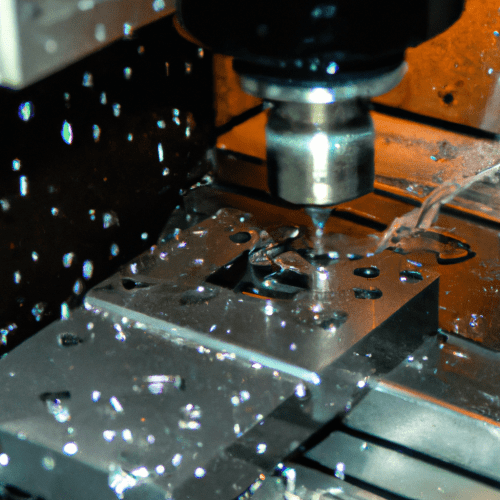

CNC milling is a machining process that uses computer numerical control (CNC) to control the movement of a cutting tool in a machine. It is a type of subtractive manufacturing process, where material is removed from a workpiece to create a desired shape or finish. CNC milling is a versatile process that can be used to create a variety of shapes and features on a workpiece.

To begin CNC milling, the workpiece must be securely clamped to the machine table. The cutting tool is then loaded into the spindle and the desired cutting parameters are entered into the CNC controller. The CNC controller will then move the cutting tool in the desired direction and at the desired speed to create the desired shape or feature. The cutting tool is then moved to the next position and the process is repeated until the desired shape or feature is achieved.

The cutting tool used in CNC milling can vary depending on the material being machined and the desired shape or feature. Common cutting tools used in CNC milling include end mills, drill bits, and reamers. The cutting tool is typically made from high-speed steel or carbide and is designed to cut through the material being machined.

The cutting speed and feed rate of the cutting tool are two of the most important parameters when CNC milling. The cutting speed is the speed at which the cutting tool moves through the material and is typically measured in meters per minute (m/min). The feed rate is the speed at which the cutting tool is fed into the material and is typically measured in millimeters per minute (mm/min). The cutting speed and feed rate must be carefully adjusted to ensure that the desired shape or feature is achieved without damaging the workpiece.

CNC milling is a precise and efficient process that can be used to create a variety of shapes and features on a workpiece. It is important to understand the process and the parameters that affect the cutting process in order to achieve the desired results.

What is the process of CNC milling?

CNC (Computer Numerical Control) milling is a machining process that uses computer-controlled cutting tools to remove material from a workpiece in order to create a desired shape or finish. The process is typically used to create complex parts with precise dimensions and shapes.

The CNC milling process begins with the creation of a 3D model of the desired part. This model is then converted into a set of instructions, known as G-code, which is used to control the cutting tool. The G-code is then loaded into the CNC machine, which is typically a vertical or horizontal milling machine.

The CNC machine is then set up with the appropriate cutting tools, such as end mills, drills, and reamers. The cutting tools are then positioned in the machine and the workpiece is secured in place. The CNC machine is then programmed to move the cutting tool in a specific pattern, which is determined by the G-code instructions.

Is it hard to learn CNC machining?

Learning CNC machining can be a challenging process, but it is also a rewarding one. CNC machining is a complex process that requires a great deal of knowledge and skill. It involves programming a computer to control the movements of a machine tool, such as a lathe or milling machine, to produce a desired shape or finish on a workpiece. To become proficient in CNC machining, one must have a thorough understanding of the principles of machining, the various types of machine tools, and the programming language used to control the machine.

In addition to the technical knowledge required, CNC machining also requires a great deal of practice. It is important to become familiar with the machine tools and the programming language, as well as the various cutting tools and materials used in the process. It is also important to understand the safety protocols associated with CNC machining, as well as the proper maintenance and troubleshooting techniques.

Can you use a CNC router as a mill?

Yes, a CNC router can be used as a mill. A CNC router is a computer-controlled cutting machine used to cut a variety of materials, such as wood, plastic, metal, and foam. It is similar to a mill in that it uses a cutting tool to shape and form materials, but it is different in that it is computer-controlled and can be programmed to cut a variety of shapes and sizes.

CNC routers are typically used for cutting and shaping wood, plastic, and metal, but they can also be used to mill materials such as aluminum, brass, and steel. The cutting tool used in a CNC router is usually a router bit, which is a rotating cutting tool with a sharp cutting edge. The router bit is mounted on a spindle and is driven by a motor. The motor is controlled by a computer, which is programmed to move the router bit in a specific pattern to cut the material.

How CNC machine works step by step?

A CNC (Computer Numerical Control) machine is a type of automated machine tool that uses computer programs to control the movement of the machine’s tools. CNC machines are used to create parts and components with high precision and accuracy. The steps involved in the operation of a CNC machine are as follows:

1. Programming: The first step in the operation of a CNC machine is to create a program that will control the machine’s movements. This program is typically created using a CAD (Computer Aided Design) software package. The program will contain instructions for the machine to move its tools in a specific order and at a specific speed.

2. Setting up the Machine: Once the program has been created, the machine must be set up for the job. This includes loading the program into the machine’s memory, setting up the tools and materials, and ensuring that the machine is properly aligned.

What are the steps of the milling process?

Milling is a machining process that uses a rotating cutting tool to remove material from a workpiece. The milling process begins with the selection of the appropriate type of milling cutter for the material to be machined. The cutter is then mounted on the spindle of the milling machine and the workpiece is clamped in place.

The next step in the milling process is to set the cutting parameters, such as the feed rate, spindle speed, and depth of cut. The feed rate is the speed at which the cutter is moved across the workpiece, while the spindle speed is the rotational speed of the cutter. The depth of cut is the amount of material that is removed with each pass of the cutter.

Once the cutting parameters have been set, the milling process can begin. The cutter is moved across the workpiece in a series of passes, with each pass removing a small amount of material. The depth of each pass is determined by the depth of cut setting.

What is CNC milling used for?

CNC (Computer Numerical Control) milling is a machining process that uses computer-controlled cutting tools to shape and fabricate parts from a variety of materials. It is a versatile process that can be used to create a wide range of components, from simple to complex shapes. CNC milling is used in a variety of industries, including aerospace, automotive, medical, and consumer products.

CNC milling is used to create parts with complex shapes and features that would be difficult or impossible to create with traditional machining methods. It is also used to create parts with tight tolerances and intricate details. CNC milling is a subtractive process, meaning that material is removed from the workpiece to create the desired shape. The cutting tools used in CNC milling are typically made of high-speed steel or carbide and are mounted in a spindle that rotates at high speeds.

CNC milling is a highly automated process that can be used to produce parts with high accuracy and repeatability.

What is CNC milling and turning?

CNC (Computer Numerical Control) milling and turning are two of the most common machining processes used in the manufacturing industry. CNC milling is a subtractive manufacturing process that uses computer-controlled cutting tools to remove material from a workpiece in order to create a desired shape or geometry. CNC turning is a subtractive manufacturing process that uses computer-controlled cutting tools to remove material from a rotating workpiece in order to create a desired shape or geometry.

CNC milling is typically used to create complex shapes and features in a workpiece, such as slots, pockets, and contours. The cutting tool is typically a rotating end mill that is moved in three axes (X, Y, and Z) to create the desired shape. The cutting tool is usually held in a spindle that is driven by a motor. The workpiece is typically held in a vise or clamped to a table.

How does a milling machine work?

A milling machine is a tool used to shape and form solid materials such as metal and wood. It typically uses a rotating cutting tool to remove material from the workpiece in a variety of directions. The cutting tool can be moved in multiple directions and depths to create a variety of shapes and sizes.

The milling machine consists of a table, which is the workpiece, and a spindle, which is the cutting tool. The spindle is mounted on a motor that rotates the cutting tool at a high speed. The cutting tool is usually a drill bit, end mill, or router bit. The cutting tool is held in place by a collet, which is a type of chuck that holds the cutting tool in place.

The table is mounted on a bed, which is a platform that can be moved in the X, Y, and Z directions. The bed is moved by a leadscrew, which is a type of screw that is used to move the bed in a precise manner. The leadscrew is driven by a motor, which is usually a stepper motor.

What is CNC turning process?

CNC (Computer Numerical Control) turning is a machining process used to create parts with cylindrical features by rotating a cutting tool while the material is held in a chuck. The cutting tool is typically a single-point cutting tool, but can also be a multi-point tool. The cutting tool is fed into the rotating material, which is held in a chuck, and the cutting tool is then moved along the axis of rotation to create the desired shape. The cutting tool is then retracted and the material is rotated to the next cutting position. This process is repeated until the desired shape is achieved.

CNC turning is a highly automated process that is used to produce parts with high accuracy and repeatability. It is used in a variety of industries, including automotive, aerospace, medical, and consumer products. The process is also used to create complex shapes, such as threads, grooves, and tapers. CNC turning is a cost-effective way to produce parts with high precision and repeatability.