Rapid prototyping is a process used to develop a prototype of a product or part in a short amount of time. ProtoLabs is a leading provider of rapid prototyping services, with the ability to quickly turn product ideas into reality. ProtoLabs utilizes a combination of 3D printing, CNC machining, and injection molding to quickly produce parts and prototypes. With 3D printing, ProtoLabs can quickly create prototypes with complex geometries and intricate details. CNC machining enables ProtoLabs to create custom parts in a range of materials for functional testing. Injection molding is used to quickly produce production-grade plastic parts. ProtoLabs also offers a range of services to assist customers with the rapid prototyping process.

These services include design for manufacturability (DFM) reviews, engineering consultation, and materials selection assistance. ProtoLabs’ experienced team of engineers and technicians are available to provide guidance and advice throughout the rapid prototyping process. ProtoLabs is a trusted provider of rapid prototyping services, with the ability to quickly turn product ideas into reality. Its combination of 3D printing, CNC machining, and injection molding allow for rapid production of prototypes and parts. Furthermore, its experienced team of engineers and technicians are available to provide guidance and advice throughout the rapid prototyping process.

How Rapid Prototyping with ProtoLabs is Revolutionizing the Manufacturing Industry

Rapid prototyping with ProtoLabs is revolutionizing the manufacturing industry by providing companies with a fast, reliable, and cost-effective way to create high-quality parts and products. ProtoLabs is a digital manufacturing platform that provides rapid prototyping services with a quick turnaround time. The platform is designed to automate the entire process, from the design and development of the product to the production of the parts and components. Using ProtoLabs’ rapid prototyping services, companies can design and develop parts and products quickly, with a turnaround time of as little as one day. The platform is equipped with advanced software and powerful machines that can produce high-precision parts with complex geometries and intricate details. The platform also offers a variety of materials such as metals, plastics, and composites, allowing companies to create parts and products with the exact specifications required.

The platform is also equipped with advanced quality assurance systems, ensuring that all parts and products meet the highest levels of quality and reliability. The rapid prototyping services offered by ProtoLabs enable companies to save both time and money. Companies no longer have to wait weeks or months for a prototype to be designed and developed. Instead, they can produce a prototype in a matter of days, allowing them to quickly move forward with the product development process. Additionally, the cost of rapid prototyping is significantly lower than traditional prototyping methods, allowing companies to reduce their overall costs. Furthermore, the rapid prototyping services offered by ProtoLabs enable companies to reduce the risk of errors and defects in the parts and products they produce.

The platform uses advanced software to automatically detect and correct any errors or defects in the parts and components produced, ensuring that all parts and products meet the highest levels of quality and reliability. In conclusion, ProtoLabs’ rapid prototyping services are revolutionizing the manufacturing industry by providing companies with a fast, reliable, and cost-effective way to create high-quality parts and products. The platform’s advanced software and powerful machines enable companies to design and develop a prototype in a matter of days, while its quality assurance systems ensure that all parts and products meet the highest levels of quality and reliability. By using ProtoLabs’ rapid prototyping services, companies can reduce their overall costs and minimize the risk of errors and defects in their products.

Benefits of Rapid Prototyping with ProtoLabs for Product Designers

Rapid prototyping with ProtoLabs is an invaluable resource for product designers, allowing them to create highly detailed prototypes quickly and efficiently. By leveraging the latest technology, ProtoLabs provides a cost-effective way for product designers to bring their ideas and concepts to life in a fraction of the time and cost of traditional manufacturing methods. Here are some of the key benefits of ProtoLabs’ rapid prototyping services for product designers:

1. Speed: ProtoLabs’ automated processes and advanced technologies allow designers to create prototypes faster than ever before. With ProtoLabs, designers can go from concept to prototype in as little as one day, allowing them to move through the design and development process quickly and efficiently.

2. Cost: With ProtoLabs, product designers are able to create prototypes at a fraction of the cost of traditional manufacturing methods. This makes it easier for designers to create multiple iterations of their designs to test and refine, without worrying about the cost.

3. Precision: ProtoLabs’ state-of-the-art CNC machines and 3D printing technologies are able to create highly detailed and accurate prototypes, giving product designers the ability to create highly complex parts and shapes. This allows designers to create prototypes that are as close to the final product as possible, ensuring that their designs are viable and functional.

4. Flexibility: ProtoLabs offers a wide range of materials and processes, giving product designers the flexibility to create the type of prototype that best suits their needs. With a range of materials, such as metals, plastics, and composites, designers can choose the perfect material for their design.

5. Support: ProtoLabs’ experienced engineering team is available to assist product designers throughout the entire process, from concept to prototype. They provide helpful guidance and advice to ensure that designers are able to bring their ideas to life in the most efficient and cost-effective way possible. Overall, ProtoLabs’ rapid prototyping services offer product designers a wealth of benefits, allowing them to bring their ideas to life faster and more cost-effectively than ever before.

With their advanced technologies, wide selection of materials, and experienced support team, product designers can create high-quality, accurate prototypes in a fraction of the time and cost of traditional manufacturing methods.

Understanding the Different Technologies Used in Rapid Prototyping with ProtoLabs

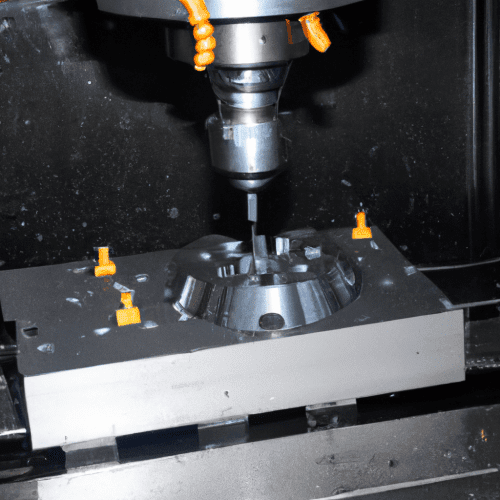

Rapid prototyping is a manufacturing technique used to rapidly create physical objects from 3D CAD (computer-aided design) data. This process has revolutionized product design and development, allowing companies to quickly create prototypes to test before investing in costly tooling and manufacturing processes. ProtoLabs is a leading provider of rapid prototyping services, offering a range of technologies for creating prototypes from plastic and metal. ProtoLabs’ rapid prototyping services include a variety of technologies, each with its own advantages for specific applications. Three of the most common rapid prototyping technologies used by ProtoLabs are CNC Machining, 3D Printing, and Injection Molding. CNC Machining is a subtractive manufacturing process that uses computer-controlled cutting tools to remove material from a block of material, such as metal or plastic, to create a part with the desired shape.

CNC Machining is ideal for producing parts with complex geometries that would be difficult to achieve with other methods. It is also great for creating parts that need to be machined to exact tolerances. 3D Printing is an additive manufacturing process that creates parts by depositing material layer by layer from a digital 3D model. This process is ideal for creating complex geometries that would be difficult to create with other methods. It is also great for creating parts with intricate details, such as texturing and color gradients. Injection Molding is a manufacturing process that creates parts by injecting molten material into a mold. Injection Molding is ideal for producing parts with complex geometries and tight tolerances, and it’s great for creating parts with a consistent surface finish. It is also great for producing large batches of parts quickly and cost effectively. ProtoLabs’ rapid prototyping services are ideal for creating prototypes quickly and cost effectively. By utilizing the right combination of technologies, ProtoLabs can provide customers with the right solution for their specific applications.

Exploring the Future of Rapid Prototyping with ProtoLabs

Rapid prototyping is the process of quickly creating a prototype for the purpose of testing a concept, design, or process. It is a key component of the product development process, allowing businesses to quickly iterate and adjust their designs in response to customer feedback or market trends. ProtoLabs is a leading provider of rapid prototyping services, offering a range of options including 3D printing, CNC machining, injection molding, and more. In this article, we will explore the future of rapid prototyping with ProtoLabs and discuss how their services are helping businesses bring products to market faster and more efficiently. ProtoLabs’ primary focus is on providing high-quality rapid prototyping services to their customers.

Through their online platform, customers can quickly and easily upload their designs and receive quotes for their projects in minutes. This enables them to quickly iterate their designs and create prototypes with minimal lead times. Additionally, ProtoLabs’ experienced project engineers are available to provide guidance and technical advice to help customers ensure their prototypes meet their desired specifications. ProtoLabs is also committed to staying on the cutting edge of rapid prototyping technology. They recently announced a partnership with Carbon, a leading provider of Digital Light Synthesis technology. Through this partnership, ProtoLabs is now able to offer customers access to Carbon’s printing technology, which enables them to create prototypes with greater accuracy and detail than ever before. In addition, ProtoLabs is exploring the use of other advanced technologies such as 3D metal printing, which could dramatically reduce lead times for certain complex projects. Finally, ProtoLabs is committed to providing customers with an easy and convenient prototyping experience. They are continuously exploring ways to streamline their processes and make the rapid prototyping experience more efficient and cost-effective.

For example, they recently implemented a new feature that allows customers to track the progress of their order in real-time, enabling them to stay informed throughout the prototyping process. As the rapid prototyping industry continues to evolve, ProtoLabs is committed to providing customers with the best possible products and services. Through their commitment to staying at the forefront of rapid prototyping technology, their partnership with Carbon, and their efforts to streamline their processes, ProtoLabs is well-positioned to remain a leader in the industry for years to come.

Tips for Working Effectively with ProtoLabs for Rapid Prototyping Projects

1. Provide clear and comprehensive design specifications: Before beginning a project with ProtoLabs, be sure to provide them with clear and comprehensive design specifications. This includes detailed drawings, material requirements, and any other important information that will help them to accurately evaluate your project and provide you with an accurate quote and timeline.

2. Work closely with ProtoLabs engineers: ProtoLabs engineers are highly experienced and knowledgeable in rapid prototyping. It’s important to work closely with them throughout the project to ensure you get the most out of ProtoLabs’ services. Ask questions and get feedback to ensure your design meets all your needs.

3. Pay attention to details: Be sure to provide ProtoLabs with detailed information about your project. This includes material specifications, design requirements, and any other important details that will help them to accurately evaluate your project and provide a timely quote.

4. Be flexible: Rapid prototyping is a fast-paced process and there can be unexpected changes along the way. Be flexible and prepared to make adjustments as needed to ensure the best possible outcome.

5. Provide feedback: Be sure to provide ProtoLabs with feedback throughout the project. This will help them fine-tune their services and ensure that the results meet your expectations.