The biggest disadvantage of using CNC is the high cost of setting up and maintaining the machinery. Highly skilled technicians are required to operate and program the machines, and the machines require regular maintenance and upkeep. Additionally, CNC machinery is often bulky and takes up a significant amount of space.

How to Overcome the Challenges of Working with CNC

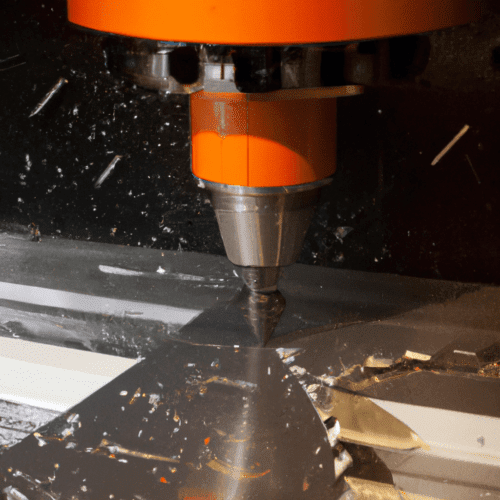

Working with CNC machinery can be a challenging endeavor, but the rewards are well worth the effort. To ensure a successful CNC project, it is important to understand the steps involved and be aware of the common challenges that arise. Here are some tips to help you overcome the challenges of working with CNC.

1. Familiarize yourself with the machine: Before you begin working with CNC, familiarize yourself with the machine’s capabilities and limitations. Learn the different controls, understand the programming language, and practice running test programs.

2. Prepare the workpiece: Properly preparing the workpiece is essential for a successful outcome. Make sure the workpiece is securely clamped in place, and that the cutting tool is sharp and correctly positioned.

3. Check the programming code: Check the programming code before you run the program to make sure it is free of errors and that it will produce the desired outcome.

4. Monitor the machine: Monitor the machine while it is running to make sure the program is running correctly and that the workpiece is being machined properly.

5. Troubleshoot problems: If you encounter any problems while running the program, stop the machine and troubleshoot the issue. Common problems include mistakes in the programming code, incorrect tool positioning, or a damaged workpiece. By following these tips, you can ensure that your CNC project will be successful. With the right preparation and monitoring, you can confidently work with CNC machinery and overcome any challenges that arise.

What are the Financial Implications of Investing in CNC Machinery?

Investing in CNC machinery can have considerable financial implications. The initial cost of purchasing the machinery, as well as the cost of installation, maintenance and repairs can be significant. Additionally, ongoing operational costs such as materials and labor must be taken into account. In order to ensure the long-term success of the investment, businesses must carefully consider the cost-benefit of CNC machinery and its ability to increase productivity and reduce errors. It is also important to consider the potential for increased profits derived from the sale of CNC-made products, as well as the potential cost savings associated with reduced labor and improved efficiency. Ultimately, businesses must weigh the financial implications of CNC machinery against the potential return on investment to ensure a successful financial outcome.

What Safety Considerations Should be Taken When Utilizing CNC Machinery?

When operating CNC machinery, safety is paramount. To ensure the safety of operators, the following considerations should be taken:

1. Proper training: All operators should be properly trained in the safe operation of CNC machinery. This includes understanding the hazards associated with operating the machine, as well as the appropriate procedures for setting up, operating, and shutting down the machine.

2. Protective equipment: Protective equipment, such as safety glasses, gloves, and hearing protection, should be worn when operating the CNC machine. Additionally, guards should be in place to shield operators from any moving parts of the machine.

3. Machine maintenance: The CNC machine should be regularly inspected and maintained to ensure it is in proper working order and free of any potential hazards.

4. Emergency stop: The machine should be equipped with an emergency stop button that operators can use in case of an emergency.

5. Fire safety: A fire safety plan should be in place in the event of a fire. Fire extinguishers should be available and easily accessible. By following these safety considerations, operators can ensure their safety when operating CNC machinery.

Understanding the Limitations of CNC Machinery

CNC machinery offers tremendous advantages in terms of speed, accuracy, and consistency, but it also carries certain limitations. It is important to understand these limitations in order to ensure the best results with CNC machinery. The most significant limitation is the complexity of the programming language used to control the machinery. This programming language is highly complex and difficult to master, and mistakes can lead to costly errors. In addition, complex designs require a great deal of time and effort to program into the machine. Another limitation of CNC machines is the material constraints. Certain types of materials, such as soft metals or plastics, are difficult for CNC machines to cut. If a wrong material is used, the tool may become damaged, and the job may have to be restarted. CNC machines are also limited in terms of their size. They are generally limited to a certain size range, and larger parts may need to be cut in multiple pieces. This can be time-consuming and labor-intensive. Finally, it is important to note that CNC machines require regular maintenance and repairs. This can be costly and time-consuming, and can lead to production delays. Overall, CNC machines offer powerful advantages, but it is important to be aware of their limitations in order to ensure the best possible results. With proper care and attention, CNC machines can provide valuable results.

Strategies for Maximizing Efficiency when Working with CNC

1. Ensure all CNC machines are properly maintained to reduce downtime. Regularly check for broken or worn-out parts and replace them as needed.

2. Create detailed and accurate programs for the CNC machine to follow. This will reduce the time needed for machining and minimize errors.

3. Use an appropriate cutting speed and feed rate. This will help to ensure smooth and accurate cuts while also helping to reduce tool wear.

4. Utilize the proper tooling for the job. The wrong tool can cause poor quality cuts and extra time spent on re-machining.

5. When possible, use multiple tools on one CNC spindle. This will reduce the time spent on tool changes and maximize the machine’s efficiency.

6. Utilize programs like G-code to help maximize the machine’s capabilities. This will help to reduce the time spent programming and increase the accuracy of the cuts.

7. When programming CNC machines, use a simulation to ensure the tool paths are correct. This will help to reduce the time spent on re-machining and minimize potential mistakes.

8. Use the proper coolant when machining. This will help to reduce the heat generated from cutting and maximize the cutting tool’s life.

9. Take advantage of automation when possible. This will help to reduce labor costs, reduce setup times, and improve machining accuracy.

10. Utilize 3D printing or rapid prototyping to quickly test parts before machining. This will help to reduce the time spent on re-machining and minimize waste.