CNC stands for Computer Numerical Control, and it is a type of automation used in the manufacturing industry. It is a process in which a computer is used to control the movement of a machine tool, such as a lathe, milling machine, or router. The computer is programmed with a set of instructions that tell the machine tool how to move and what operations to perform. CNC machines are used to produce a wide variety of products, from simple parts to complex components. CNC machines are highly accurate and can produce parts with very tight tolerances. They are also capable of producing parts with complex shapes and intricate details. CNC machines are used in a variety of industries, including aerospace, automotive, medical, and consumer products. CNC machines are also used in the production of furniture, musical instruments, and toys.

What is CNC design?

CNC design is the process of creating a 3D model of a part or product using computer-aided design (CAD) software. This 3D model is then used to create a CNC program, which is a set of instructions that tells a CNC machine how to manufacture the part or product. CNC design is used in a variety of industries, including automotive, aerospace, medical, and consumer products.

The CNC design process begins with the creation of a 3D model of the part or product. This model is created using CAD software, which allows the designer to create a 3D representation of the part or product. The model is then used to create a CNC program, which is a set of instructions that tells the CNC machine how to manufacture the part or product. The CNC program is then loaded into the CNC machine, which is then used to manufacture the part or product.

What is the meaning of CNC cutting?

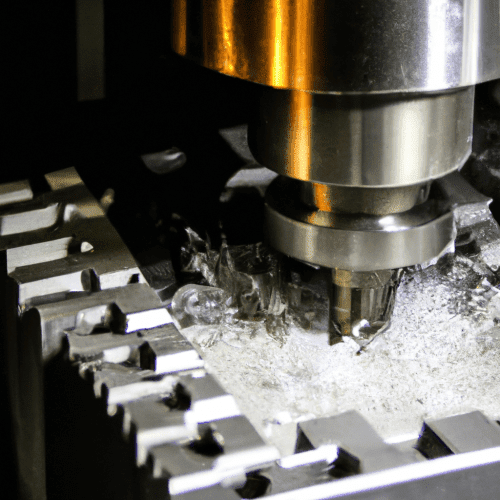

CNC (Computer Numerical Control) cutting is a manufacturing process that uses computer-controlled cutting tools to shape and cut materials into specific shapes and sizes. It is a form of subtractive manufacturing, which is the process of removing material from a larger piece of stock to create a desired shape or design. CNC cutting is used in a variety of industries, including aerospace, automotive, medical, and consumer products.

The CNC cutting process begins with a CAD (Computer Aided Design) file that contains the design of the part to be cut. This file is then loaded into the CNC machine, which is programmed to move the cutting tool along the desired path. The cutting tool is typically a router, laser, or waterjet, and is used to cut the material into the desired shape. The cutting tool is guided by the CNC machine, which is programmed to move the cutting tool along the desired path.

The CNC cutting process is highly accurate and repeatable, and can be used to create complex shapes and designs with a high degree of precision.

What is the correct full form of CNC?

The correct full form of CNC is Computer Numerical Control. CNC is a type of automation technology used in the manufacturing industry to control machine tools such as lathes, mills, routers, and grinders. It is a computer-controlled system that uses numerical data to control the movement of the machine tools. CNC machines are programmed with a set of instructions that tell the machine how to move and what operations to perform. This allows for precise and repeatable machining operations, which can be used to create complex parts with high accuracy and repeatability. CNC machines are used in a variety of industries, including aerospace, automotive, medical, and consumer products.

What is CNC experience?

CNC experience is the knowledge and skill gained from operating a CNC (Computer Numerical Control) machine. CNC machines are automated machines that are programmed to perform specific tasks, such as cutting, drilling, and milling. CNC experience is important for those who work in the manufacturing industry, as it allows them to produce parts and components with precision and accuracy.

CNC experience is gained through hands-on training and practice. This involves learning how to program the machine, as well as how to operate it. It also involves understanding the different types of CNC machines, their capabilities, and how to troubleshoot any issues that may arise. Additionally, CNC experience includes understanding the safety protocols and procedures that must be followed when operating a CNC machine.

CNC experience is beneficial for those who are looking to enter the manufacturing industry, as it allows them to produce parts and components with precision and accuracy. It also allows them to troubleshoot any issues that may arise, and to understand the safety protocols and procedures that must be followed when operating a CNC machine.