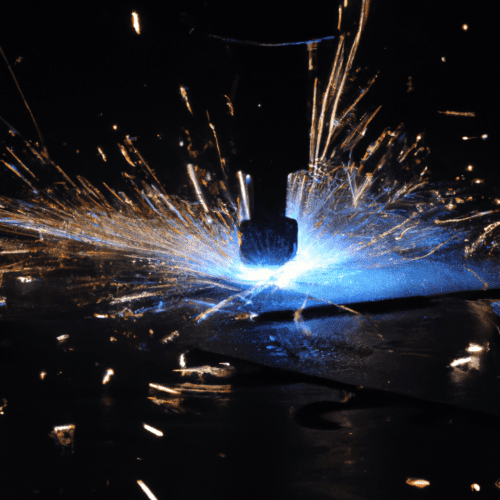

Plasma cutting is a process of cutting through materials using an accelerated jet of hot plasma. It is often used in industrial metal fabrication and has become a popular choice for many industrial cutting applications due to its versatility, accuracy, and affordability. The process of plasma cutting works by using a combination of electrical energy, gas, and a constricted opening to create an extremely hot and fast-moving plasma arc. The plasma arc is then directed towards the material being cut by a torch, and the material is then melted or burned away as the arc passes through it. The result is a clean, precise cut that is free of burrs or other imperfections. Plasma cutting can be used on a wide variety of materials, including steel, aluminum, copper, brass, stainless steel, and plastics. It can be used to cut through thick and thin materials with equal ease, making it a great choice for many industrial cutting applications. In addition to its versatility, plasma cutting offers a number of advantages over traditional cutting methods. It is much faster than traditional cutting methods, and it produces a smoother, cleaner cut with less heat distortion.

It is also much more cost-effective than other cutting methods and is often used in conjunction with other cutting methods, such as oxyacetylene or laser cutting, to further increase the efficiency of the cutting process. Overall, plasma cutting is a great choice for many industrial cutting applications due to its speed, efficiency, and affordability. Its versatility and accuracy make it a popular choice for many industrial applications, and its affordability makes it an attractive option for businesses looking to reduce their costs.

Exploring the Benefits of Plasma Cutting: Why It’s the Preferred Choice

Plasma cutting is one of the most efficient and cost-effective metal fabrication techniques used by manufacturers around the world. It is a process that utilizes a high-velocity stream of ionized gas to cut through electrically conductive materials such as steel, stainless steel, aluminum, brass, and copper, among others. This cutting method is often preferred over traditional mechanical cutting techniques due to its higher accuracy, speed, and flexibility. One of the primary benefits of plasma cutting is its speed and efficiency. Compared to traditional mechanical cutting methods, plasma cutting can cut faster and with greater accuracy. This is because the plasma cutting torch is capable of producing a high-velocity stream of ionized gas, which can cut through even the toughest materials at a fraction of the time. Additionally, the plasma cutting process is less prone to errors, as it requires fewer steps and less set up time. In addition to its speed and efficiency, plasma cutting offers several other advantages. For instance, it can be used to cut intricate shapes and patterns, which are difficult to achieve with traditional cutting methods.

Furthermore, the plasma cutting process is known for its extreme precision and can be used to create complex shapes with very high tolerances. With this kind of precision, manufacturers can achieve a greater level of accuracy in their products. Finally, plasma cutting is a relatively low-cost solution for metal fabrication. Compared to other types of cutting, plasma cutting requires only minimal amounts of electricity and does not require costly consumables such as welding rods. In addition, the plasma cutting process is relatively safe and does not generate excessive levels of heat or smoke, making it suitable for use in confined spaces. In conclusion, plasma cutting is a preferred choice for many manufacturers due to its speed, accuracy, flexibility, and cost-effectiveness. It is a reliable and efficient metal fabrication process that offers a range of benefits to manufacturers.

How Plasma Cutting Technology Has Evolved Over Time

Plasma cutting technology has come a long way since its invention in the early 1950s. The first plasma cutters were bulky and unreliable, using manual controls and limited power sources to produce relatively rough cuts in materials such as steel. Today, plasma cutting is a highly automated and precise process that can produce intricate shapes and smooth, precise edges. This transformation has been driven by the development of more powerful, reliable power sources and computerized controls that allow for precise, automated cutting. The most modern plasma cutters use CNC (computer numerical control) technology to allow for extremely precise cuts. CNC-controlled plasma cutters use a combination of computer programming and feedback from physical sensors to accurately control the cutting speed, force, and length of the cut.

This makes it possible to produce complex shapes with the highest degree of accuracy. The development of more powerful, efficient power sources has also been a major factor in the evolution of plasma cutting technology. The most modern plasma cutters are capable of cutting thicker materials with higher cutting speeds than ever before. This has allowed for faster cutting times and more efficient production of complex shapes. In addition to the advances in power sources and CNC technology, the development of plasma cutting torches has also contributed to greater precision and efficiency. Modern plasma torches use a combination of high-pressure gases and electricity to create a powerful, focused arc that can produce clean, precise cuts with minimal heat distortion. Overall, the evolution of plasma cutting technology has allowed for greater precision, speed, and efficiency in the production of intricate shapes. The combination of more powerful power sources, computerized controls, and advanced torches has allowed for the production of complex shapes with the highest degree of accuracy and minimal heat distortion. This evolution has revolutionized the way manufacturers create components and products, allowing for greater efficiency and cost savings.

The Advantages of Plasma Cutting Over Other Cutting Processes

Plasma cutting has been around since the 1950s and has since become the preferred cutting process for many manufacturing and fabrication businesses. It is a cost-effective and accurate process, and it offers a number of advantages over other cutting processes. The primary advantage of plasma cutting is its accuracy. Plasma cutting can produce precise cuts with minimal waste and distortion, making it ideal for intricate shapes and patterns. This is especially true when compared to more traditional cutting processes such as oxy-fuel and saw cutting, which are not as accurate and can produce edges that are not as clean. Plasma cutting is also much faster than other processes. It can be used to cut through thick metal quickly and easily, which can be a huge time saver.

Additionally, the cutting speed can be adjusted to suit the needs of the job, allowing for faster production times. Finally, plasma cutting is a relatively safe process. It does not require the use of any flammable materials, like oxygen or acetylene, and it is much less noisy than other cutting processes. This makes it a great choice for environments where safety is a top priority. Overall, plasma cutting offers a number of advantages over other cutting processes. Its accuracy, speed, and safety make it ideal for many fabrication and manufacturing applications. Additionally, its cost effectiveness and lack of need for hazardous materials make it an attractive choice for businesses on a budget.

Tips for Achieving the Best Results with Plasma Cutting

Plasma cutting is a process that uses high-temperature, high-velocity plasma to cut through conductive metals. It is an effective and efficient way to cut metal, and it produces a clean, smooth edge with minimal heat affected zone (HAZ). However, it is important to take the necessary steps to ensure the best results with this process. Here are some tips for achieving the best results with plasma cutting: • Prepare the metal: Before beginning the cutting process, it is important to prepare the metal surface. This means cleaning it, removing any rust or dirt, and grinding away any sharp edges. This will ensure that the plasma has a smooth surface to cut through and will create a better-quality cut.

- Use the right nozzle: It is important to use the right nozzle when plasma cutting. The nozzle size should be chosen based on the thickness of the metal. A smaller nozzle will produce a narrower, more precise cut, while a larger nozzle will produce a wider, less precise cut.

- Adjust the speed: The speed of the plasma cutting process should be adjusted based on the material being cut. A slower speed will result in a cleaner cut, while a faster speed will produce a rougher cut.

- Adjust the amperage: The amperage of the plasma should also be adjusted based on the material being cut. A lower amperage will produce a cleaner cut, while a higher amperage will produce a rougher cut.

- Choose a good cutting table: A good cutting table is essential for achieving the best results with plasma cutting. The table should be large enough to accommodate the material being cut, and it should be able to withstand the heat generated by the plasma.

- Use the correct gases: Depending on the material being cut, different gases may be required. Argon is typically used for stainless steel, while air is used for mild steel. It is important to use the correct gas for the material being cut to ensure the best results. Following these tips will help ensure the best results with plasma cutting. Taking the time to properly prepare the metal and adjust the amperage, speed, and gases is essential for achieving the best results.

Plasma Cutting Applications: Where It’s Used and Why It’s so Effective

Plasma cutting is one of the most versatile and effective cutting processes available for use in industrial applications. It is widely used in a variety of industries, such as metal fabrication, automotive, aerospace, and HVAC. Plasma cutting is capable of cutting through a wide range of materials, including steel, stainless steel, aluminum, copper, brass, and other metals. The process of plasma cutting involves the use of a directed stream of hot gas, such as an inert gas like argon or nitrogen, to create a high-energy channel of plasma. This plasma is then used to cut through the material. The heat generated by the plasma is so intense that it melts and vaporizes the material, separating it from the workpiece. One of the advantages of plasma cutting is its speed and accuracy. Plasma cutting systems are designed to provide precise cuts with minimal material loss.

This process can produce cuts that are straight, curved, or beveled, depending on the shape of the cutting nozzle. Additionally, the cutting speed of plasma cutting systems is faster than other cutting processes, such as oxy-fuel cutting or water jet cutting. Plasma cutting is also very cost-effective. It requires a relatively low initial capital investment and does not require additional labor costs. Additionally, the process is relatively safe, as the cutting process is highly automated and requires minimal operator intervention. Overall, plasma cutting is highly effective and efficient for a variety of applications. It is capable of producing high-quality cuts with minimal waste, is fast and accurate, and is cost-effective. As a result, it is widely used in many industrial applications.