Nano Dimension is at the forefront of additive manufacturing and 3D printing technologies, revolutionizing the way they design and prototype in the electronics industry. With its innovative technology and high-resolution printing capabilities, Nano Dimension is transforming the world of advanced manufacturing.

With a focus on PCB prototyping, Nano Dimension combines nanotechnology, materials science, and process development to deliver cutting-edge solutions for rapid prototyping. Their intelligent machines integrate 3D printing with advanced robotics, hardware, and software, reinventing analog and manual processes.

Key Takeaways

- Nano Dimension is a leader in the field of 3D printing and additive manufacturing.

- Their high-resolution printing capabilities enable rapid prototyping in the electronics industry.

- Nano Dimension combines nanotechnology, materials science, and process development to deliver innovative solutions.

- Their intelligent machines integrate 3D printing with advanced robotics, hardware, and software.

- By reinventing analog and manual processes, Nano Dimension is transforming advanced manufacturing.

Revolutionizing Design and Production with Industry 4.0 Solutions

Industry 4.0 is paving the way for a new era of manufacturing efficiency, and Nano Dimension is at the forefront of this transformative movement. By integrating advanced factory robotics, cutting-edge hardware, and sophisticated software developments, including neural-network Deep Learning AI, Nano Dimension is revolutionizing design and production processes.

With Industry 4.0 solutions, Nano Dimension is creating an all-digital system that streamlines operations, enhances productivity, and optimizes manufacturing efficiency. By harnessing the power of neural-network Deep Learning AI, Nano Dimension’s digital system takes manufacturing to new heights, enabling automated processes, predictive maintenance, and real-time analytics for data-driven decision-making.

This digital transformation brings numerous benefits to the manufacturing industry, including improved operational efficiency, reduced downtime, enhanced quality control, and increased production flexibility. By leveraging advanced technologies, Nano Dimension is pushing the boundaries of what is possible in design and production, enabling companies to gain a competitive edge in today’s fast-paced and dynamic market.

Maximizing Manufacturing Efficiency through Advanced Robotics and Digital Systems

At the core of Nano Dimension’s Industry 4.0 solutions is the integration of advanced factory robotics. These robots work seamlessly with the digital system to automate repetitive tasks, eliminate errors, and accelerate the production process. By reducing manual intervention, companies can achieve greater manufacturing efficiency, cost savings, and improved overall performance.

The digital system utilized by Nano Dimension enables seamless connectivity between different stages of the production line, ensuring synchronized operations and optimized resource utilization. Through real-time monitoring, the system identifies bottlenecks, detects anomalies, and provides valuable insights for process optimization, resulting in enhanced productivity and reduced time to market.

Unleashing the Power of Neural-Network Deep Learning AI

Neural-network Deep Learning AI plays a pivotal role in Nano Dimension’s Industry 4.0 solutions, empowering manufacturing processes with intelligent decision-making capabilities. By analyzing vast amounts of data, the AI algorithms identify patterns, predict outcomes, and optimize production parameters for maximum efficiency and quality.

Through continuous learning and adaptation, the neural-network Deep Learning AI becomes more efficient over time, leading to improved production processes, reduced waste, and enhanced product innovation. Its ability to identify potential issues before they occur enables proactive measures, such as preemptive maintenance or adjustments, ensuring uninterrupted manufacturing operations.

With its groundbreaking Industry 4.0 solutions, Nano Dimension is driving the future of design and production. By embracing advanced robotics, digital systems, and neural-network Deep Learning AI, Nano Dimension is helping companies unlock their full potential and achieve superior manufacturing efficiency in the age of Industry 4.0.

Unprecedented 3D Printing Capabilities for Manufacturing Excellence

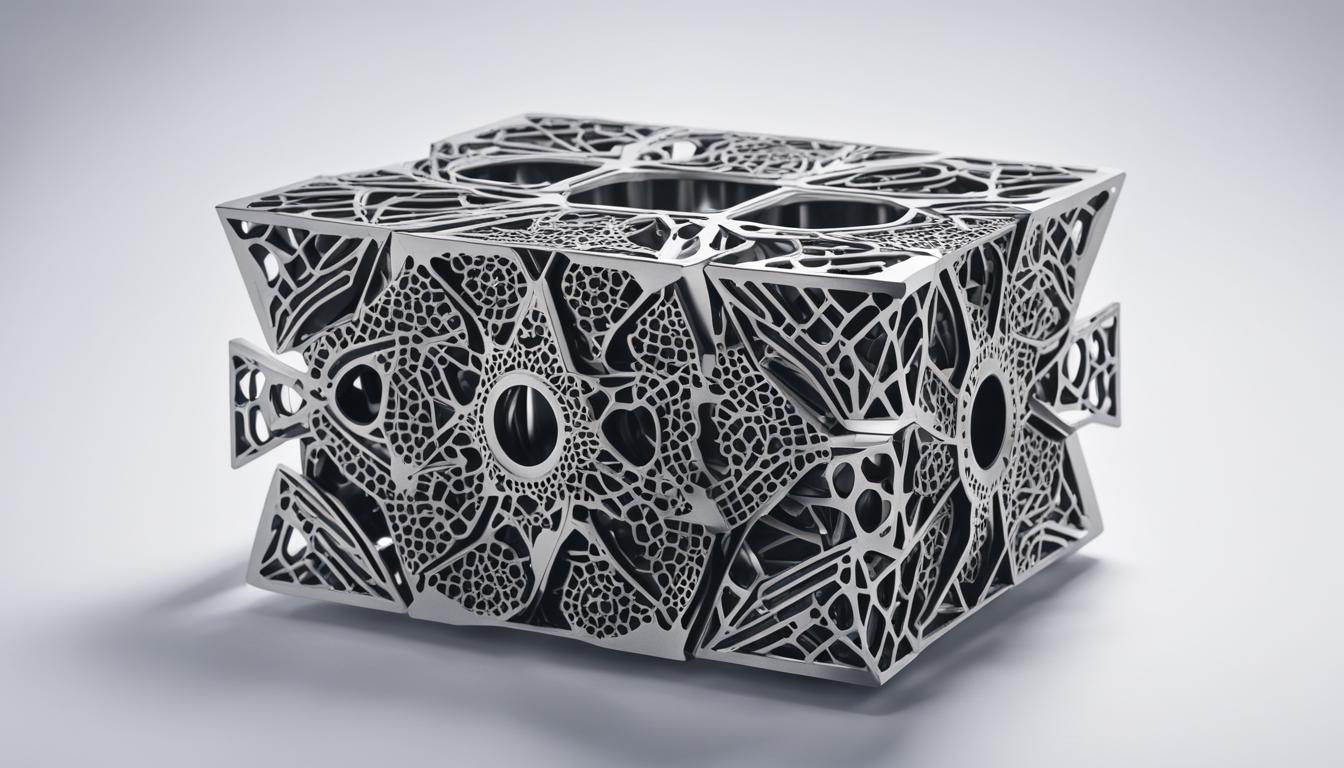

Nano Dimension, a leading provider of intelligent machines, offers unprecedented 3D printing capabilities that drive manufacturing excellence. The company’s advanced additive robotics manufacturing equipment, including robotics systems and additive manufacturing equipment, enables digital-industrial production in various industries, particularly electronics manufacturing. These cutting-edge systems deliver sophisticated innovation and facilitate the creation of reliable, short-order supply chains for sectors such as aerospace, defense, and high-tech manufacturing.

Advanced Additive Robotics Manufacturing Equipment

Nano Dimension’s advanced additive robotics manufacturing equipment is at the forefront of modern manufacturing. These systems integrate robotics systems and cutting-edge additive manufacturing equipment, revolutionizing digital-industrial production. By leveraging these technologies, customers in the electronics manufacturing field can enhance their production process, achieving high-quality output and accelerated time-to-market.

Sophisticated Innovation and Supply Chain Optimization

Through the utilization of Nano Dimension’s 3D printing capabilities, companies can achieve unprecedented levels of innovation. These advanced additive robotics manufacturing systems enable the production of complex electronics with precision and efficiency. By streamlining the manufacturing process, businesses can optimize their supply chains, ensuring prompt delivery of high-quality products to meet market demands.

| Features of Nano Dimension’s 3D Printing Capabilities: | Benefits for Manufacturing Excellence: |

|---|---|

| Integration of robotics systems and additive manufacturing equipment | Enhanced precision and efficiency in production process |

| Sophisticated innovation in electronics manufacturing | Opportunity for groundbreaking product development |

| Reliable and short-order supply chains | Accelerated time-to-market and customer satisfaction |

Nano Dimension’s commitment to delivering unparalleled 3D printing capabilities has solidified its position as a leader in the manufacturing industry. With a focus on robotics systems, additive manufacturing equipment, and digital-industrial production, Nano Dimension continues to push the boundaries of innovation, providing customers in the electronics manufacturing sector with the tools they need for manufacturing excellence.

Expanding Market Reach with Strategic Partnerships

Nano Dimension, a global leader in 3D printing technology, is expanding its market reach by forging strategic partnerships with industry leaders. One such partnership that holds immense promise is the collaboration with AURORA Group, a renowned market leader in the manufacturing sector.

AURORA Group’s extensive resources and network, combined with Nano Dimension’s cutting-edge technology, create a powerful synergy that enables both companies to tap into new opportunities. This strategic partnership opens doors to the Asia Pacific market, with a specific focus on China, known for its rapid growth in the 3D printing industry.

Through this collaboration, Nano Dimension aims to market and sell its flagship product, the DragonFly 2020 Pro 3D printer for electronics, in China. The DragonFly 2020 Pro is an award-winning solution that enables high-precision 3D printing of electronics, revolutionizing the manufacturing process.

With the support of AURORA Group, Nano Dimension gains a significant advantage in penetrating the Asian market and meeting the increasing demand for innovative 3D printing solutions. The growth potential of the 3D printing market in China, combined with government initiatives and investments, makes this strategic partnership even more compelling.

To gain a better understanding of this collaboration and its impact, let’s explore the benefits and opportunities it brings to Nano Dimension and AURORA Group:

Benefits of the Strategic Partnership

The partnership between Nano Dimension and AURORA Group offers several key advantages:

- Access to AURORA Group’s extensive resources and network, allowing Nano Dimension to establish a strong presence in the Asian market.

- The opportunity to market and sell the DragonFly 2020 Pro 3D printer for electronics in China, tapping into the country’s booming 3D printing market.

- Collaboration on research and development initiatives to further enhance the capabilities and applications of 3D printing technology in electronics manufacturing.

- Joint efforts in driving awareness and adoption of additive manufacturing solutions in China, promoting the benefits of 3D printing for various industries.

This strategic partnership not only strengthens Nano Dimension’s position as a market leader in 3D printing technology but also enables AURORA Group to offer its customers cutting-edge solutions for electronics manufacturing.

Together, Nano Dimension and AURORA Group are poised to drive the growth of the 3D printing market in China and the Asia Pacific region. With their combined expertise and resources, they are well-positioned to unlock new possibilities and accelerate the adoption of additive manufacturing in diverse industries.

AURORA Group’s Commitment to Innovation and High-Quality Solutions

AURORA Group, as Nano Dimension’s leading partner in China, is dedicated to delivering cutting-edge 3D printing solutions and high-quality products to its customers. Through its strategic collaboration with Nano Dimension, AURORA expands its portfolio to include advanced capabilities for 3D printing electronics. Their collaboration introduces the DragonFly 2020 Pro, a groundbreaking technology that revolutionizes the possibilities of additive manufacturing in the electronics industry.

With the DragonFly 2020 Pro, electronics designers and manufacturers can now explore new avenues of innovation and create functional electronic devices with unmatched precision and efficiency. This groundbreaking technology combines the power of additive manufacturing with sophisticated materials science and process development, offering a comprehensive solution for the production of high-quality, customized electronics.

AURORA Group’s Commitment to Innovation and Quality

AURORA Group is committed to being at the forefront of technology and innovation, constantly striving to provide its customers with the latest advancements in 3D printing solutions. As a trusted partner, AURORA combines its expertise in the manufacturing industry with Nano Dimension’s groundbreaking technology to deliver high-quality products and transformative solutions to their customers.

Capabilities for 3D Printing Electronics

Through this strategic partnership, AURORA Group gains access to state-of-the-art 3D printing technology that enables the production of complex electronic components with unparalleled precision. With capabilities for 3D printing electronics, AURORA can now serve a wider range of industries, including aerospace, defense, and high-tech manufacturing, providing them with the tools they need to innovate and succeed.

Advancing Additive Manufacturing

The DragonFly 2020 Pro is a testament to AURORA Group and Nano Dimension’s joint commitment to advancing additive manufacturing. By harnessing the power of this groundbreaking technology, AURORA is empowering its customers to embrace the future of electronics manufacturing, where customization, efficiency, and innovation intersect.

Tapping into China’s Lucrative Electronics Manufacturing Market

China, known for being one of the largest and most influential players in the electronics manufacturing and design industry, holds immense potential for companies seeking growth opportunities. This is why Nano Dimension, a leading provider of intelligent manufacturing solutions, recognizes the importance of establishing a foothold in the Chinese market.

With China’s extensive presence and strong government support in the electronics industry, Nano Dimension aims to tap into this lucrative market by partnering with AURORA Group, a prominent manufacturing leader in China.

AURORA Group’s vast network and operating experience provide Nano Dimension with fast market access and a platform for success. By leveraging AURORA’s resources and expertise, Nano Dimension can effectively introduce their cutting-edge technology to the Chinese electronics manufacturing market.

China’s commitment to driving technological advancements, coupled with their substantial investments in 3D printing, further enhances the market’s potential for Nano Dimension. This allows the company to meet the growing demand for advanced electronics manufacturing solutions.

By strategically positioning themselves in the Chinese market, Nano Dimension aims to not only expand their business opportunities but also contribute to the overall growth and innovation in the electronics manufacturing industry.

| Advantages of Tapping into the Chinese Market | Market Access | Extensive Presence | Government Support | Investments in 3D Printing |

|---|---|---|---|---|

| Opportunity to reach a vast consumer base | Establishment of strong partnerships for market entry | Access to an extensive network of manufacturers | Supportive policies and initiatives driving innovation | Availability of funding for technology advancements |

| Development of localized products and services | Reduced barriers to entry | Existing infrastructure for manufacturing operations | Promotion of high-tech industries | Integration of 3D printing in various sectors |

| Collaboration with local partners for market insights | Customer acquisition and market penetration | Availability of skilled workforce | Incentives and subsidies for technology companies | Growth potential in the additive manufacturing sector |

By capitalizing on the Chinese electronics manufacturing market, Nano Dimension is strategically positioning themselves for growth and success in a rapidly evolving industry. Through their partnership with AURORA Group and the support of the Chinese government, Nano Dimension aims to provide advanced electronics manufacturing solutions that meet the unique needs of the Chinese market.

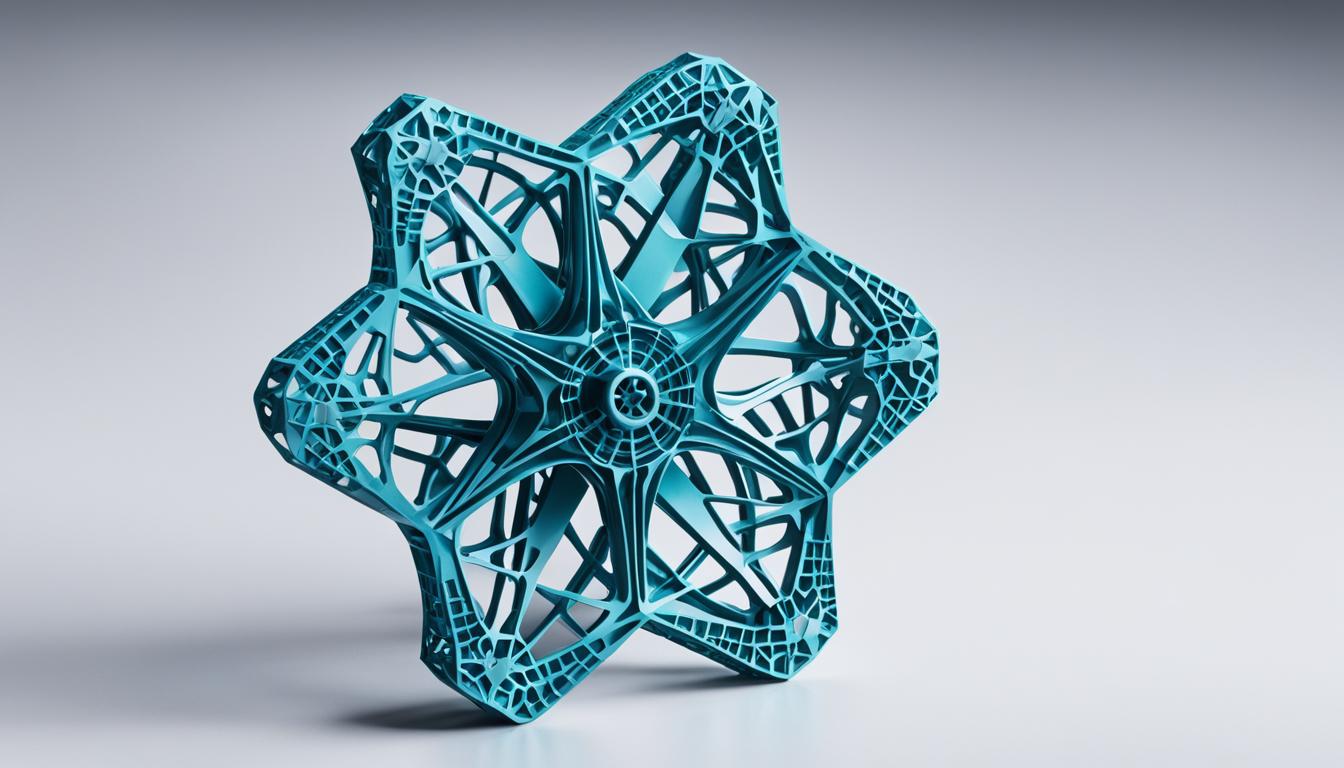

Transforming Electromechanical Development with the DragonFly 2020 Pro

The DragonFly 2020 Pro 3D printer from Nano Dimension is revolutionizing electromechanical development, empowering companies to take full control of their development cycle. This cutting-edge system enables the 3D printing of functional electronics, including encapsulated sensors, conductive geometries, antennas, molded connected devices, and printed circuit boards. With the ability to produce these innovative devices, Nano Dimension is enabling electronics designers and manufacturers to accelerate their product development and bring their ideas to life like never before.

The Benefits of the DragonFly 2020 Pro

The DragonFly 2020 Pro offers a range of benefits that transform the way electromechanical development is conducted:

- Efficiency: By leveraging 3D printing technology, companies can reduce the time and costs associated with traditional manufacturing processes.

- Design Freedom: The DragonFly 2020 Pro provides designers with the freedom to explore complex geometries and create functional electronics with intricate features.

- Rapid Prototyping: With the ability to quickly iterate designs and produce functional prototypes in-house, developers can significantly accelerate their product development cycles.

- Customization: The system allows for on-demand production of fully customizable components, tailored to specific project requirements.

- Reduced Waste: By eliminating the need for traditional subtractive manufacturing processes, such as CNC machining, the DragonFly 2020 Pro minimizes material waste and environmental impact.

With the DragonFly 2020 Pro, Nano Dimension is driving innovation in electromechanical development, enabling companies to bring their product ideas to life faster and more efficiently. This groundbreaking technology opens up new possibilities for the design and production of functional electronics, setting a new standard for the industry.

Case Study: Encapsulated Sensors for IoT Applications

| Traditional Manufacturing | DragonFly 2020 Pro |

|---|---|

| Lengthy production process with multiple steps | Streamlined one-step production with shorter turnaround times |

| High material waste due to subtractive manufacturing | Minimal material waste through additive manufacturing |

| Limited design flexibility and customization options | Freedom to create complex geometries and fully customizable designs |

| Long lead times for iterations and design changes | Rapid prototyping capabilities for quick iterations and design improvements |

The DragonFly 2020 Pro has proven its capabilities in the production of encapsulated sensors for IoT applications. Compared to traditional manufacturing methods, the DragonFly 2020 Pro offers significant advantages, such as streamlined production, reduced waste, enhanced design flexibility, and faster iterations. This case study showcases the transformative power of the DragonFly 2020 Pro in the development of functional electronics.

Commitment to Responsible Innovation and Sustainability

Nano Dimension is dedicated to fostering responsible innovation and addressing key environmental, social, and governance (ESG) opportunities and risks. The company recognizes the importance of reducing the environmental impact of its technologies and operations, embracing sustainable practices in the dynamic manufacturing industry.

Environmental Impact

At Nano Dimension, minimizing the environmental impact of its operations and products is a top priority. The company actively seeks ways to optimize its energy consumption, reduce waste generation, and implement eco-friendly practices throughout its manufacturing processes.

Social Responsibility

Nano Dimension is committed to upholding high standards of social responsibility within its organization and beyond. The company promotes fair labor practices, prioritizes employee safety and well-being, and actively invests in initiatives that support local communities.

Governance and Ethics

As a responsible innovation leader, Nano Dimension adheres to stringent governance and ethical standards. The company maintains transparency, accountability, and integrity in its decision-making processes to ensure the highest level of professionalism and trustworthiness.

Corporate Sustainability Initiatives

Nano Dimension is actively involved in various sustainability initiatives to drive positive change in the manufacturing industry. The company collaborates with partners, associations, and government bodies to promote sustainable practices, foster innovation, and develop eco-friendly solutions.

Continual Improvement

Nano Dimension recognizes that responsible innovation and sustainability are ongoing journeys. The company remains dedicated to continually improving its processes, technologies, and practices to minimize its environmental footprint and positively impact society.

| Key Environmental Initiatives | Social Responsibility Initiatives | Governance and Ethics Initiatives |

|---|---|---|

|

|

|

Expertise across Engineering Disciplines

Nano Dimension is proud to have a highly skilled team with a wide range of expertise across multiple engineering disciplines. Our team members are specialists in materials science, advanced process development, electronics, neural network artificial intelligence, and additive 3D printing technologies. This diverse knowledge base allows us to continuously push the boundaries of innovation and deliver cutting-edge solutions to our customers.

At Nano Dimension, they understand the importance of interdisciplinary collaboration in driving advancements in the manufacturing industry. Our team’s collective expertise enables us to develop and implement advanced manufacturing processes that integrate materials science, electronics, and artificial intelligence. By harnessing the power of additive 3D printing technologies, they can create complex and functional prototypes with precision and efficiency.

Whether it’s optimizing materials for specific applications, developing advanced process techniques, or leveraging neural network artificial intelligence for intelligent design, Nano Dimension’s team of experts is at the forefront of innovation. They are dedicated to pushing the boundaries of what is possible and delivering industry-leading solutions that drive progress in various sectors.

Materials Science and Advanced Process Development

Materials science is at the core of our innovation. Our team of materials scientists continuously researches and develops new materials that meet the demanding requirements of modern manufacturing. By understanding the properties, behavior, and interactions of different materials, they can optimize their use in additive manufacturing processes. This expertise allows us to select and develop materials that offer high strength, flexibility, heat resistance, and other critical properties required for specific applications.

In addition to materials science, they also specialize in advanced process development. Our engineers are constantly exploring new techniques and refining existing processes to improve efficiency, accuracy, and speed. Through continuous experimentation and optimization, they can offer advanced process solutions that meet the unique needs of our customers.

Electronics and Neural Network Artificial Intelligence

With our deep understanding of electronics and neural network artificial intelligence, they can integrate intelligent design solutions into our additive manufacturing processes. This enables us to create functional and optimized designs for complex electronic systems, including printed circuit boards (PCBs) and other electronic components. Our expertise in these areas allows us to optimize designs for performance, reliability, and manufacturability.

By leveraging neural network artificial intelligence, they can analyze and interpret complex data sets to improve design accuracy and optimize manufacturing processes. This advanced technology allows us to identify patterns, make predictions, and generate design recommendations, enabling our customers to achieve higher levels of efficiency and innovation in their manufacturing processes.

With our expertise across various engineering disciplines, Nano Dimension is well-equipped to drive advancements in the additive manufacturing industry. Our commitment to innovation and pushing the boundaries of what is possible allows us to deliver cutting-edge solutions to our customers, enabling them to stay ahead in a rapidly evolving manufacturing landscape.

Continuous Investment in Research and Development

In order to drive technological fabrication innovation, Nano Dimension places a strong emphasis on research and development. The company’s continuous investment in R&D enables them to develop and deliver advanced manufacturing systems that cater to the evolving needs of their customers. By staying at the forefront of innovation in the additive manufacturing industry, Nano Dimension provides unique organizations with access to their state-of-the-art systems.

Through their commitment to research and development, Nano Dimension pushes the boundaries of what is possible in the world of advanced manufacturing. Their team of experts constantly explores new materials, processes, and technologies to enhance the capabilities of their systems and ensure that they remain at the cutting edge of the industry.

One of the key focuses of Nano Dimension’s research and development efforts is finding innovative ways to improve the speed and precision of their manufacturing systems. By leveraging their unique organization and expertise, they aim to revolutionize the production process and make it more efficient, cost-effective, and sustainable.

To illustrate the impact of their continuous investment in R&D, here is a table highlighting some of the key technological advancements achieved by Nano Dimension:

| Technological Advancement | Description |

|---|---|

| High-resolution 3D Printing | Nano Dimension has developed advanced printing technologies that enable high-resolution printing with exceptional accuracy, allowing for the creation of intricate and precise components. |

| Multi-material Printing | Their systems are capable of printing with multiple materials simultaneously, enabling the production of complex, multi-functional parts with varying properties. |

| Embedded Electronics | Nano Dimension has pioneered the integration of electronics directly into 3D-printed structures, eliminating the need for traditional assembly methods and reducing production time and costs. |

| Smart Software Solutions | They have developed intelligent software solutions that optimize the design and manufacturing processes, ensuring compatibility with their advanced systems and maximizing efficiency. |

Through their continuous investment in research and development, Nano Dimension is driving technological fabrication innovation and revolutionizing the additive manufacturing industry. By delivering advanced manufacturing systems with unparalleled capabilities, they empower organizations to unleash their creativity, accelerate production, and realize the full potential of additive manufacturing.

Career Opportunities with Nano Dimension

Are you passionate about innovative technologies and high-tech manufacturing? Look no further than Nano Dimension for exciting career opportunities in the additive manufacturing industry. As a global leader in 3D printing innovation, Nano Dimension is continuously seeking talented individuals with expertise in various engineering disciplines.

At Nano Dimension, they believe in pushing the boundaries of what is possible. Our team of experts in materials science, advanced process development, electronics, neural network artificial intelligence, and additive 3D printing technologies work together to develop groundbreaking solutions that shape the future of technology.

Joining Nano Dimension means being part of a dynamic, forward-thinking organization that is revolutionizing the manufacturing industry. By contributing your skills and knowledge, you will play a crucial role in driving advancements in high-tech manufacturing and innovative technologies.